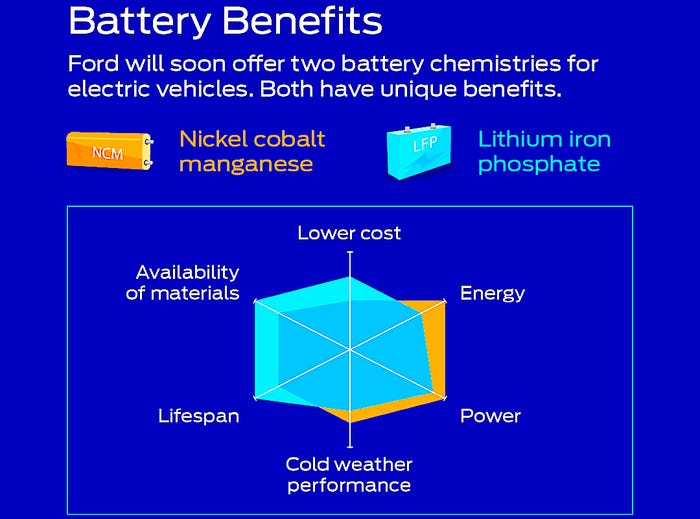

This alternative lithium-ion battery technology has unique strengths compared to current nickel cobalt manganese chemistry EV batteries.

February 21, 2023

Ford’s announcement that it is building a plant to make lithium iron phosphate (LFP) EV batteries has raised the profile of this alternative EV battery chemistry. So far, it has seen little use in the U.S., but it is more widely used in other countries.

Ford has good reason to diversify away from nickel cobalt manganese (NCM) batteries despite those batteries’ own advantages, explains the company’s global director of electrified systems engineering, Charles Poon. “Currently, the nickel and cobalt used in these batteries are in high demand, with limited supply, making them particularly expensive,” he said. “So later this year, Ford will introduce a new type of battery on some electric models.”

Even before the Ford announcement, the research company Fortune Business Insights was forecasting dramatic growth for this technology. The global lithium iron phosphate battery market size is projected to rise from $10.12 billion in 2021 to $49.96 billion in 2028 at a 25.6 percent compound annual growth rate during the assessment period 2021-2028, according to the company’s research report, titled, “Global Lithium Iron Phosphate Battery Market, 2021-2028.”

“Lithium iron phosphate (LFP) battery packs have gained traction to offer high voltage, power density, long life cycle, less heating, and increased safety,” the report notes. “Soaring demand for electric vehicles will boost the popularity of LFP battery components.”

Poon outlined the pros and cons of each in a presentation for the announcement of the new factory. “NCM batteries have a higher power rating and energy density, which means they can travel long distances and greater loads,” he explained. “They hold up well in colder conditions.”

Nevertheless, there are reasons to consider LFP batteries. “LFP batteries can charge faster, which means less of a wait to get back on the road,” said Poon. “The materials in LFP batteries make it more affordable to produce and will help Ford make EVs accessible to more customers. Plus, they tend to be more durable and have a longer projected lifespan.”

LFP batteries will make sense for some kinds of customers for whom the maximum range on a charge is not the overriding factor. “All of the LFP benefits are attractive for certain kinds of customers, such as business owners who run the same routes with their vehicles over and over again and charge frequently,” Poon stated. “Or someone who mainly uses their EV on shorter, routine commutes like dropping the kids off at school and going to work. We believe there’s an advantage to having both types of batteries, NCM and LFP in the Ford lineup”

Recognizing the interest in LFP technology for heavy trucks, Cummins issued a list of five fast facts to know about LFP batteries:

An LFP is a lithium-ion battery. The Li-Ion battery family contains different battery chemistries named after their cathode. Other lithium-ion batteries include the nickel manganese cobalt oxide (NMC) battery and the lithium nickel cobalt aluminum oxides (NCA) battery.

The “F” in LFP stands for iron. The “F” comes from “Fe,” the periodic table of elements chemical symbol for iron. Fe is derived from the Latin word for iron, ferrum.

LFPs can be charged to 100 percent. It is considered best practice to avoid a very high and meager charge in NMC and NCA batteries, with 80 percent being the standard battery capacity for an optimal lifetime. However, LFPs have 100 percent of their capacity available, meaning they can be fully charged without causing accelerated battery degradation.

LFPs are a lower-cost option. LFP batteries currently bypass supply chain issues and inflated prices because nickel and cobalt aren’t needed for the cathode. An LFP’s cathode is made from earth-abundant materials from the olivine mineral family, which is an abundant primary component of the Earth’s upper mantle.

17 percent of the global EV market is powered by LFPs. This battery chemistry is poised to make its next big breakthrough with large-scale adoption in different on-highway applications like electric buses and electric trucks.

The researchers at Gartner pointed out other advantages of using LFP battery chemistry:

“The batteries also have better safety characteristics and do not explode under extreme conditions. LFP batteries also eliminate the concerns of cobalt entering the environment through improper disposal once they have expired.”

With so many advantages in exchange for lower power density, it seems certain that LFP batteries will gain a meaningful portion of the EV battery market share in the near future.

About the Author(s)

You May Also Like