The successful commercialization of the lithium-ion battery is boosting the conception of safer and improved separator technologies.

When the first practical prototype of a lithium ion battery (LIB) was created at Asahi Kasei under the direction of Dr Akira Yoshino in 1985, the most notable innovation was a highly functional membrane separator—a particularly important factor in achieving the safety required for successful LIB commercialization.

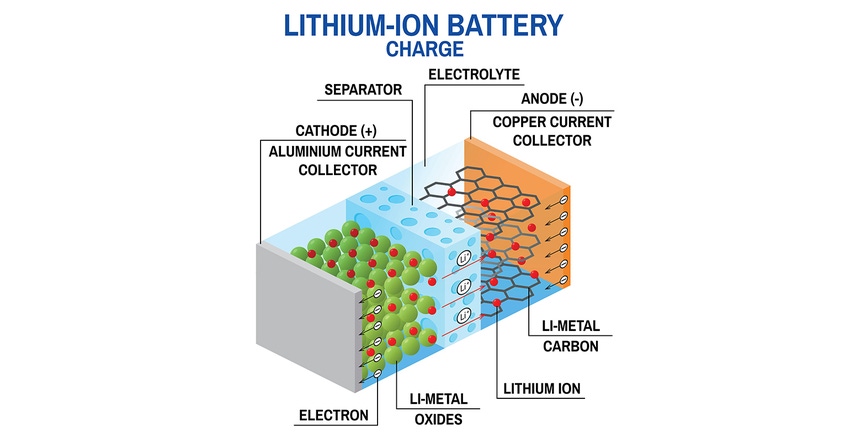

A separator is one of the most important components in a LIB. It is located between the anode and the cathode to prevent physical contact between electrodes and at the same time the separator can facilitate the transference of ions in the cell. A failure in the separator can trigger a short circuit of the cell that could cause thermal runaway.

Depending on the application, an ideal separator should include the following characteristics:

Large electrolyte uptake

As thin as possible to not add dead volume

Chemically and electrochemically stable

Appropriate uniformly porosity level

Wettability

Right impedance

Optimal Cycle life

It is a great challenge to balance all the above characteristics to create a technology that is not only safe and efficient but cost-effective. Here are some of the different technologies available right now in the LIB separator market:

Celgard: One of their solutions for battery electric vehicles applications includes the use of a polypropylene/polyethylene/polypropylene (PP/PE/PP) trilayer structure. The PP outer layers not only provide high temperature melt integrity (HTMI) which is a key property to ensure safety, but they also provide oxidative resistance. The PE inner layer provides high-speed shutdown during a thermal event.

The Celgard H1809 includes an 18 µm trilayer microporous membrane (PP/PE/PP) with a 49% of porosity. The H1809 is designed for high power lithium battery systems; especially those that require exceptional safety and energy density advantages.

UBE Corporation: Between their solutions for automobile applications, there is an option for a ceramic-coated separator called CPORE. CPORE is a high functional coated separator film which is produced by advanced dispersion technology and high speed and accuracy coating technology on the surface of separator film.

CPORE comes in different thickness ranging from 13–25 µm. Inorganic particles are applied to these separators to further increase heat resistance, minimize shrinkage due to abnormal heating and prevent shorting inside the battery, significantly improving LIB safety.

Entek: Entek offers ultra-high molecular weight polyethylene (UHMWPE) based separators in both coated and uncoated formats. One of their products—EPH—is oriented to high rate of discharge/recharge applications used in powering portable electronic devices such as cordless power tools, lawn and garden equipment, high powered RC vehicles, etc. EPH separators come in thickness between 9–16 µm with a porosity of 48%.

Soteria: Soteria's patented technology allegedly eliminates the root cause of thermal runaway, isolating short circuits and allowing cells to continue to function after damage. Soteria’s non-woven membranes are reinforced with aramid fibers, resulting in a separator that won’t melt or shrink in the presence of a defect or damage. In addition, the metallized-film current collectors burn out like a fuse, isolating the short circuit, while the rest of the cell continues to function.

Separators contribute to the safety and reliability of Li-ion batteries. R&D efforts are very active for LIB cells despite the challenges of commercializing innovative technologies. According to Graphical Research, the lithium-ion battery separator segment in North America is likely to grow at a strong CAGR of 16.2% through 2027. The road map of battery separators looks very promising with safer and better innovations in the way.

About the Author(s)

You May Also Like