Audi is building the new e-tron EV using production techniques developed entirely in virtual reality, with no physical models.

August 24, 2021

In its conversion of its Neckarsulm plant from only producing the zoomy R8 super sports car to include assembly of the e-tron electric models, Audi employed only virtual modeling to make the necessary changes to the plant. That makes the Audi e-tron GT is the first model whose production was planned entirely without physical prototypes, according to the company. Audi points to technical innovations such as three-dimensional building scans, machine learning processes, and virtual reality as the keys to developing this production entirely in virtual reality.

Assembly processes were tested and optimized in virtual space that models the real-world counterparts down to the finest detail. The permits virtual planning across site boundaries, enabling digital, connected working without business trips or foreign assignments.

“The 3-P (Production Preparation Process) process workshop using VR allows us to respond very flexibly. We can display all products, from the e-tron GT or all product variants, something we couldn’t do in the classic 3-P process workshop with the hardware,” explained Markus Moinot, who works in assembly planning processes at the Neckarsulm plant.

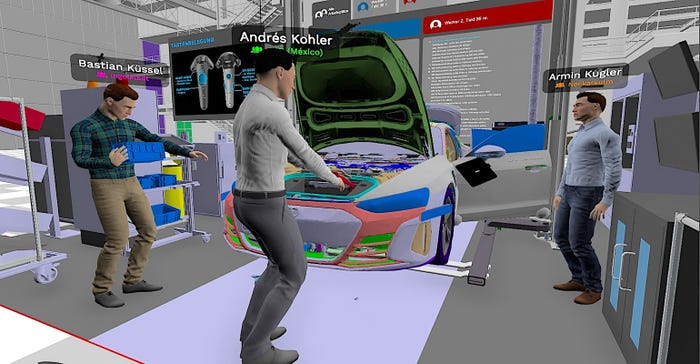

This technology is not limited to the Neckarsulm plant. Instead, it connections production colleagues at various plants for planning. “Thanks to a VR solution developed here at Audi and the digital model, colleagues from all over the world can now meet in virtual spaces and find themselves in the middle of the production facility of tomorrow," said Andrés Kohler, responsible for virtual assembly planning at Audi. "They can look over the shoulders of digital workers as they perform the planned procedures. They can also experience and optimize the planned processes for any part variants in our application.”

Although the virtual reality headsets and avatars may be unique to virtual reality systems, using it was actually familiar, reported Bernd Widdmann, assembly planning methods leader for the Ingolstadt plant. “You can think of it as something like a Skype conference," he observed. "You invite participants. They are connected on their computer, put on their glasses, and they appear as avatars in our joint scenario.”

For the question-and-answer portion, Audi's various experts on the virtual reality project collaborated to provide group answers to the questions.

Where is virtual planning used and why are 3D scans so important for this?

Audi: A variety of prototypes are used in the conventional planning process for the production of a new Audi model. The vehicle prototypes are fabricated during the early planning phase as one-off models with hand-built parts. This is time-consuming and cost-intensive. Assembly Planning uses these prototypes to define and optimize the later production processes. What are the employee’s tasks? Where does a part have to be located for the employee to have optimal access to it? Can the employee hold and install the part by him- or herself? How does she have to move to do it? Are other parts in the way? What tools does he need?

During production planning for the Audi e-tron GT, these questions were derived and answered entirely in the virtual world. Every step and every action was tested in the digital space using virtual reality. The goal of virtual planning is to ensure that during the later production of the vehicle, all processes are perfectly meshed and the cycles along the line are seamlessly coordinated. This requires that every detail of the production hall be modeled precisely and to scale. This is where 3D scans come into play. Using special hardware and software, they create a virtual reproduction of the physical production facility, including all equipment, tools and shelves.

The Audi Böllinger Höfe at the Neckarsulm site, where the Audi e-tron GT is built, thus also exist in the digital world. And thanks to new, digital planning methods, the production of tomorrow can be planned virtually years in advance on the basis of this model.

How do 3D scans work and what role does artificial intelligence play?

Audi: A scanner – the hardware – is essential for generating the corresponding data.

It is roughly two meters (6.6 ft) tall and is mounted on four wheels so that an employee can move it around the space. At the top is a lidar unit and three additional laser scanners as well as a camera. Two processes are conducted simultaneously while scanning a space: The wide-angle camera takes a picture of the space while the lasers precisely measure it and generate a three-dimensional point cloud of the surroundings. 250,000 square meters (2,690,977.6 sq ft) of production hall space at the Neckarsulm site alone has already been scanned using this technology.

But it is the interaction between the hardware and software that takes the points, images, and data sets generated and turns them into a usable overall image that can be used with the existing planning systems. The software used here is an in-house Audi development based on artificial intelligence and machine learning. The point cloud and the photographs are combined to produce a three-dimensional, photo-realistic space similar to what is seen in Google Street View. Proportions and sizes are true to scale and correspond to reality. The software also automatically recognizes all objects, such as machines, shelves, and systems in the space.

It also learns automatically with each scan to recognize, distinguish and classify objects even more precisely. For example, the system distinguishes between a shelf and a steel beam. The position of the shelf can be changed in the program later and relocated in the virtual space. That of the steel beam cannot. These data enable a virtual walk-through of the scanned production facility from any starting point and can be used directly in planning processes.

Where is virtual planning with virtual reality already being used and what advantages does it offer?

Audi: The Audi e-tron GT is the brand’s first vehicle for which the assembly procedures and associated logistics processes were tested exclusively virtually and without any physical prototypes.

To do this, a holistic, virtual model of the planned assembly with vehicle data, material handling, equipment, tools, and the planned processes is prepared as a so-called digital model. The 3D scans are one element of this. The digital model is the basis for further innovations, as the results can then be used to train employees, also on the basis of the VR application. These new possibilities are now being used in an increasing number of additional projects and at multiple sites. A 3-P (Production Preparation Process) workshop, for example, was held at the Audi site in San José Chiapa, Mexico, and project team members from Ingolstadt also took part. As digital avatars and thus completely virtually, the experts discussed and planned the production of the Audi Q5 facelift and the new Q5 Sportback in VR.

All assembly procedures are jointly defined and tested in real-time, as are ergonomic aspects or the exact arrangement of machines, shelves, and parts along the assembly line. Audi is the Group lead for the development of the comprehensive VR solution including the digital model. The project is being continued across brand lines under the leadership of the four rings as a Group project and rolled out to more and more sites.

About the Author(s)

You May Also Like