Compared with metal assemblies, large-format all-plastic housings enable cycle time reductions and contribute to lighter vehicle weight, thus extending the range of electric vehicles (EVs).

December 6, 2021

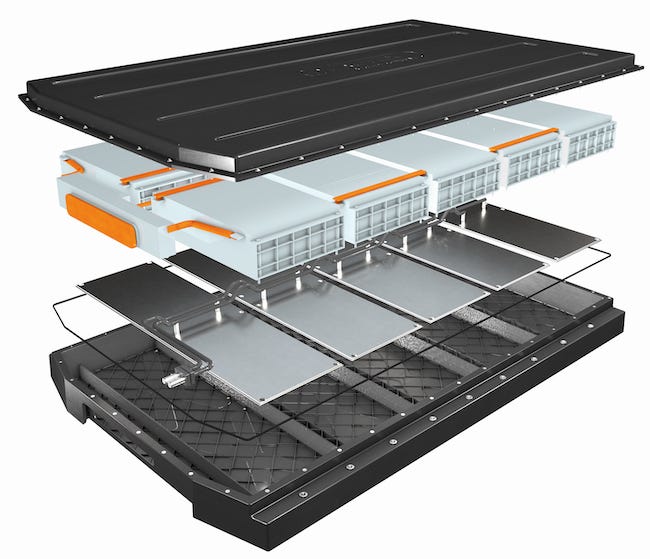

Lanxess and Kautex Textron have spent several years collaboratively researching whether battery housings for electric vehicles can be designed and manufactured from engineering thermoplastics. Using direct long-fiber thermoplastic (D-LFT) and polyamide 6 (PA 6) resins, they have developed a near-series technology demonstrator in a feasibility study. Measuring 1,400 x 1,400 mm (length x width), the system is a sophisticated, large-format all-plastic housing with a weight in the mid-double-digit kilogram range. The goal of the project was to demonstrate the advantages of thermoplastics over metals in terms of weight and cost reduction, functional integration, and electrical insulation behavior.

“As a first step, we have dispensed with the use of metallic reinforcement structures while proving we can commercially produce these complex large components,” Felix Haas, Director Product Development at Kautex Textron, explains. “Going forward, Kautex and Lanxess want to use the results of the cooperation to enter into development projects for series production with automotive manufacturers,” adds Dr. Christopher Hoefs, Project Manager e-Powertrain at Lanxess.

Single-stage manufacturing process

The demonstrator was developed based on the battery housing of a C-segment electric vehicle. It consists of a housing tray with crash structure, housing cover, and underbody protection. The housing components are produced in a single-stage D-LFT molding process, while Lanxess has optimized Durethan B24CMH2.0 polyamide 6 (PA 6) as the molding compound.

Kautex Textron compounds the PA 6 for the process with glass-fiber rovings. Local reinforcement of the housing structure is accomplished using Tepex dynalite continuous fiber-reinforced thermoplastic composites from Lanxess. “The process enables shorter and, thus, more economical cycle times than the processes in which steel or aluminum are processed,” Haas explains.

|

The demonstrator was developed based on the battery housing of a C-segment electric vehicle. It consists of a housing tray with crash structure, housing cover, and underbody protection. |

Today, housings for high-voltage batteries are primarily made of extruded steel or aluminum profiles. Depending on the vehicle class, the housing length and widths can be well over 2,000 or 1,500 millimeters, respectively. Size, component count, and the numerous manufacturing and assembly steps make metal housings very cost-intensive. For example, complex structures made from strand press profiles require many secondary work steps such as welding, punching, and riveting. In addition, the metallic components must be protected against corrosion in an additional process step by cathodic dip coating.

Assembly, logistics simplified

“Plastics, on the other hand, can fully exploit their design freedom. By integrating functions such as fasteners and thermal management components, the number of individual components of a battery housing can be greatly reduced. This simplifies assembly and logistical effort, which reduces production costs,” says Hoefs. Plastics are also corrosion-resistant and electrically insulating. The latter ensures, for example, that there is a reduced risk of the system short-circuiting. The low density of plastics and their potential for lightweight construction leads to significantly lighter housings, which benefits, among other things, the range of electric vehicles.

High-voltage battery housings must meet a variety of highly demanding requirements. For example, they must be stiff and strong and yet be able to absorb a significant amount of energy in the event of a crash. This is tested via mechanical shock and crush tests. The housings also must be flame-retardant in the event of a vehicle fire or thermal run-away of the electrical cells. Finally, the housings must be integrated into the vehicle structure.

“We continue to work together on optimizing the production and structural design of the components. The aim is to carry out the majority of the development work virtually, in order to save costs in prototype design and to shorten the time to market of future series components,” Hoefs says.

For a deeper dive into thermoplastic composites, an in-depth guide has been published on the Omnexus website.

You May Also Like