Atlis Motor Vehicle CEO Mark Hanchett discusses future business plans and AMV’s one-stop-shop for all energy storage solutions.

Mesa, Arizona-based startup Atlis Motor Vehicle (AMV) recently made news when it received an order from Australia-based AUSEV for 19,000 of its all-electric XT pickup trucks. A week later, AUSEV supplemented that order by also buying 270 AMV 1.5-MW charging stations.

That AMV makes both trucks and charging systems—not to mention its own batteries—is an example of its self-identification as not only an EV maker but “an EV technology ecosystem developer.” A recent company news release stated, “Of the EV companies in the United States—both utility and passenger—only Atlis develops its own batteries and offers that technology to other companies.” The company’s marquee battery offering is the AMV Cube Cell, which, in conjunction with one of those 1.5 MW charging stations, charges from zero to 100% in 15-minutes or less.

Battery Technology spoke to AMV founder and CEO Mark Hanchett about the challenges of building not only a truck or a battery but an ecosystem:

AMV is more than electric pickup trucks. The company offers a myriad of products from battery cells to residential and commercial energy storage solutions. What are the challenges and advantages of providing all these power solutions in one place?

Hanchett: AMV believes energy density and the cost benefits that come from offering a one-stop-shop will be advantageous to consumers. There will always be competition, especially as demand for these products increase in the coming years; AMV is up for the challenge.

What industries is AMV supplying or planning to supply in the near future?

Hanchett: AMV strives to develop the future of work by supporting those who build, dig, grow, and maintain our communities. Technology designed and developed by AMV may power box trucks, pickups, RVs, vans, cement trucks, delivery vehicles, garbage trucks, agricultural machinery, military vehicles, and more.

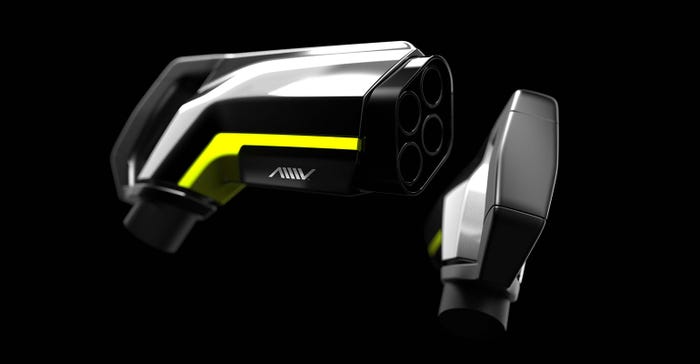

AMV is planning to fulfill an order from Australia-based AUSEV for 270 of the company’s 1.5 MW charging stations. What make AMV’s charging station stand out among competitors?

Hanchett: The Atlis Advanced Charging (AAC) system is designed to be a portable and sustainable DC and AC fast charging solution, while also supporting microgrid applications. With a multitude of connectors, from SAE J1772, CCS, preparations for MCS, and Atlis’ proprietary megawatt capable charge cable—delivering up to 1.5MW, multiple vehicles will be able to charge from one station concurrently.

The AAC system is built to be “plug and play,” allowing for flexible deployments to applications with intermittent or limited grid supply. Able to provide power back to the grid, a backup power system is also built into the design. The AAC system enables resiliency and energy buffering to reduce energy costs via intelligent software monitoring in two different ways: By requesting power from the grid when costs are low and by utilizing energy storage to reduce utility charges.

Regarding your battery pack solutions, what is the battery chemistry and capacity of the battery cells? Do they come in different sizes? Are the battery packs scalable? Where is your battery cell production located?

Hanchett: AMV battery cells are manufactured in Mesa, AZ. The battery cells are nickel manganese cobalt (NMC). The current capacity focus is 30kWh packs for select customers. The battery packs could be scaled to different pack sizes as customers request them.

AUSEV has already placed an order for 19,000 XT vehicles. Other than being fully electric, what does the XT truck offer?

Hanchett: For a work truck, range and uptime will be of the utmost importance as the market shifts to sustainable mobility. With a 500-mile range and the ability to charge from 0—100% in 15 minutes, the XT will enable the ability to get the job done. Towing 35,000 lbs. gooseneck or 5th wheel, with a payload up to 20,000lb GVWR, the XT is designed for those ready to replace their legacy diesel equipment and usher in an era of decarbonization.

Finally, how do you foresee the future of the US electric vehicle market?

Hanchett: As battery technology improves and scales, prices will drop and the shift from ICE to electric vehicles will pick up pace—even more so than we see today. AMV is committed to those preparing to make the switch by providing equipment that is less complicated and more capable to support the hard at work.

About the Author(s)

You May Also Like