BEV vs FCEV: Which Is More Sustainable?

Explore the differences between Battery Electric Vehicles (BEVs) and Fuel Cell Electric Vehicles (FCEVs) for sustainable transportation options.

The auto industry is transforming towards sustainable mobility solutions, with battery electric vehicles (BEVs) and fuel cell electric vehicles (FCEVs) emerging as leading contenders. Both technologies offer zero-emission driving, but they differ significantly in their underlying mechanisms and infrastructure requirements. This analysis delves into the key distinctions between BEVs and FCEVs, considering factors such as efficiency, infrastructure, environmental impact, and market readiness.

Energy efficiency

BEVs rely on rechargeable batteries to store and deliver electric power to an electric motor, offering high energy efficiency with minimal energy loss during operation. In contrast, FCEVs utilize hydrogen fuel cells to generate electricity through a chemical reaction between hydrogen and oxygen, converting it into electric power to drive the motor.

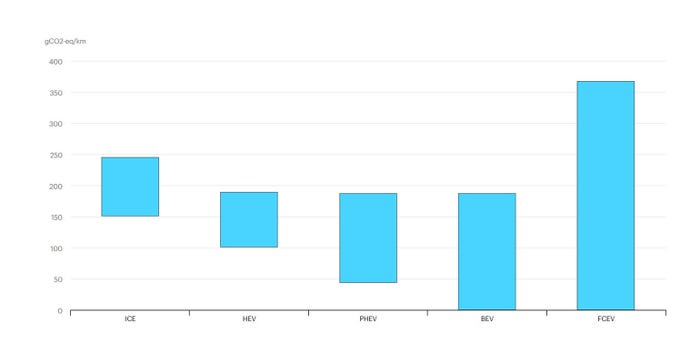

While both FCEVs and BEVs offer zero-emission transportation solutions, BEVs still exhibit higher well-to-wheel (W2W) efficiency due to their more straightforward energy conversion process and the potential for renewable electricity generation. However, advancements in hydrogen production technologies and renewable hydrogen sources could improve FCEVs' future efficiency and environmental sustainability.

IEA, Well-to-wheels greenhouse gas emissions for cars by powertrains, IEA, Paris https://www.iea.org/data-and-statistics/charts/well-to-wheels-greenhouse-gas-emissions-for-cars-by-powertrains, IEA. License: CC BY 4.0

Infrastructure

The infrastructure needed for BEVs primarily includes charging stations, spanning from residential chargers to fast-charging networks. However, despite significant advancements, the availability and accessibility of charging infrastructure poses substantial challenges for widespread BEV adoption, particularly for long-distance travel. Another obstacle is the absence of standardized charging protocols, an issue that automakers are actively addressing.

In contrast, FCEVs need hydrogen refueling stations, which are less prevalent than charging infrastructure. A robust hydrogen refueling network poses significant logistical and financial hurdles, delaying FCEVs' scalability.

Environmental impact

The environmental footprint of BEVs and FCEVs extends beyond tailpipe emissions to encompass their entire lifecycle, including manufacturing, operation, and disposal. BEVs generally perform better regarding lifecycle emissions, particularly in regions with a decarbonized electricity grid. However, producing lithium-ion batteries for BEVs demands resource extraction, energy-intensive manufacturing processes, and potential environmental ramifications associated with battery disposal and recycling.

The environmental impact of FCEVs is also subject to debate, mainly because of the source of hydrogen production. FCEVs can achieve zero tailpipe emissions if hydrogen is derived from renewable sources such as electrolysis using renewable electricity or biomass. However, if hydrogen is produced from fossil fuels, such as natural gas, it can result in greenhouse gas emissions and other pollutants, diminishing the overall environmental benefits of FCEVs.

Market readiness

BEVs have gained considerable traction in the automotive market, fueled by technological advancements, supportive policies such as EV tax credits, and growing consumer demand for sustainable transportation options. Major automakers have invested heavily in BEV development, expanding their EV portfolios and driving down costs through economies of scale.

In its second generation, the Toyota Mirai provides an EPA-estimated range rating of 402 miles on the XLE grade. Courtesy of Toyota.

FCEVs have yet to achieve widespread market penetration, constrained by infrastructure limitations, higher production costs, and limited model availability. Despite notable efforts by automakers to commercialize FCEVs, including the Toyota Mirai and Hyundai Nexo, their market presence remains niche compared to passenger cars for BEVs.

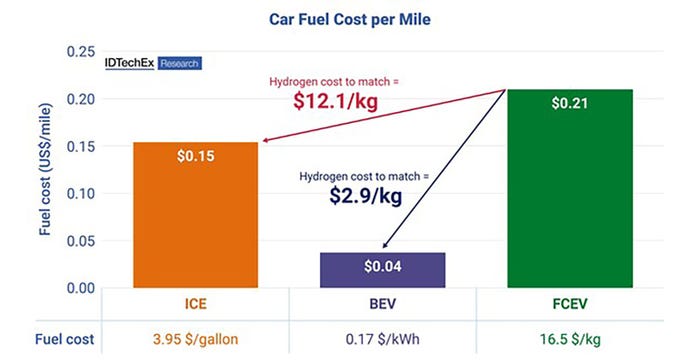

The cost of green hydrogen needs to reduce dramatically to match BEV charging costs. Courtesy of IDTechEx

Hydrogen fuel proves costly, as per IDTechEx estimates for fuel expenses in California by 2023. A Tesla Model 3 costs approximately $0.04 per mile, whereas the Toyota Mirai reaches $0.21 per mile, surpassing even gasoline cars at $0.15 per mile. To compete with BEVs, hydrogen costs would need to plummet closer to $3 per kilogram. However, regional variations may influence these figures.

Who’s the winner?

Both BEVs and FCEVs represent promising solutions for sustainable transportation, offering zero-emission alternatives to conventional internal combustion engine (ICE) vehicles. While BEVs currently enjoy broader market acceptance and infrastructure support, FCEVs hold potential for long-haul routes without frequent refueling stops. Ultimately, the success of these technologies centers on continued innovation, infrastructure development, and collaborative efforts across industry stakeholders to accelerate the transition towards a low-carbon transport future. Striking a balance between resource utilization, emissions reduction, and environmental stewardship is crucial for both technologies.

Also, many consumers are still unfamiliar with BEVs and FCEVs and may have misconceptions about their performance, range, and reliability. Educating consumers about the benefits and limitations of electric and fuel-cell vehicles is essential for increasing acceptance and adoption rates.

About the Author(s)

You May Also Like