How Conductive Additives Optimize Battery Performance

Orion SA will showcase its broad range of additives at The Battery Show North America 2023.

August 9, 2023

At The Battery Show North America 2023, global specialty chemicals company Orion SA is showcasing its broad range of high-performance conductive additives to meet the requirements and improve the performance of lithium-ion and lead-acid batteries.

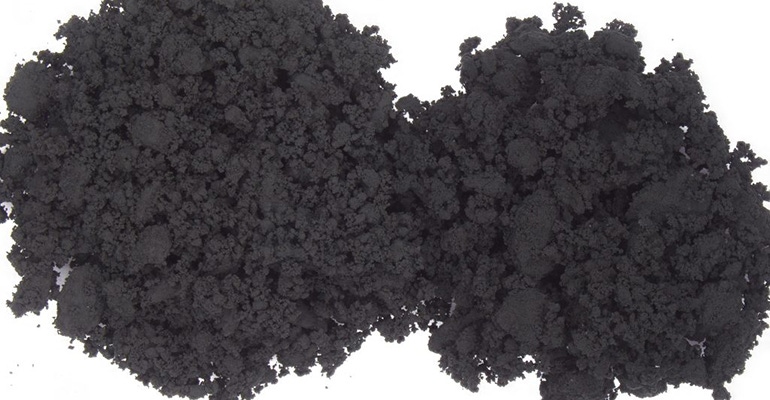

Orion is spotlighting PRINTEX kappa 100 conductive additive. Available in bead or powder form, the acetylene-based additive increases battery performance in lithium-ion batteries.

For advanced lead-acid batteries, the company is featuring its PRINTEX kappa family of products, which increases dynamic charge acceptance while maintaining acceptable water loss. Orion also offers products for standard lead-acid and primary batteries.

“We are expanding our technology portfolio in the battery industry to provide our customers suitable products and to deliver sustainable solutions, in both lead-acid and lithium-ion technology,” stated Kevin Milks, marketing manager for polymers and batteries Americas at Orion (Booth 2026). “We offer multi-disciplined chemistry—not just acetylene black but furnace black, lamp black, and gas black materials that meet battery industry needs.”

Improving conductivity in lithium-ion batteries

PRINTEX kappa 100 offers exceptional purity and imparts high electrical and thermal conductivity, leading to significantly higher power densities and longer battery life than with other carbon blacks. It forms an excellent percolation network across the cathode surface for effective charging and discharging. What’s more, PRINTEX kappa 100 is extremely dispersible, making it easier to handle and formulate, and highly hydrophobic for a longer battery lifecycle.

In addition, Orion produces acetylene black in an environmentally responsible manner. Its acetylene black production generates a high yield. As a result, PRINTEX kappa 100 has a remarkably low carbon footprint, and its sustainable chemistry contributes to the reduction of greenhouse gas emissions.

A unique production facility

Orion announced last year it is planning to build the only plant in the US producing acetylene-based conductive additives—critical for lithium-ion batteries, high-voltage cables, and other products powering the global transition to electrification and renewable energy. Planned for LaPorte, Texas, the new facility is expected to open in the first half of 2025.

“Our new production facility will help serve the increasing demand for lithium-ion batteries for electric vehicles,” stated Jennifer S. Stroh, director of specialties sales and marketing Americas. “When it goes online, it will offer North American battery manufacturers domestic availability and consistent supply.”

To learn more about Orion’s sustainability performance and initiatives, visit Orion Engineered Carbons - Sustainability - Sustainability Roadmap (orioncarbons.com).

The Battery Show and Electric & Hybrid Vehicle Technology Expo North America is in Novi, MI, September 12–14, 2023

About the Author(s)

You May Also Like