Separator Coating Facility to Speed Adoption of Li-Metal Batteries

Sepion's new plant will enable its LMB separator coatings to go from the prototype stage to pilot-scale production.

There’s a critical but often overlooked component in the lithium-ion battery manufacturing industry that empowers our portable devices, electric vehicles (EVs), and renewable energy storage solutions: separators. While electrodes and electrolytes often steal the limelight, unassuming separators ensure lithium-ion batteries' safe and efficient operation.

Sepion Technologies, an advanced materials company that creates safe and high-energy lithium-metal batteries, is dedicated to transforming the EV industry. The company uses a coated separator to increase the safety, range, and fast rechargeability of lithium-metal batteries (LMBs). In a recent milestone, Sepion unveiled the inauguration of North America's largest separator coating facility for LMBs.

The technology behind Sepion's separator coating

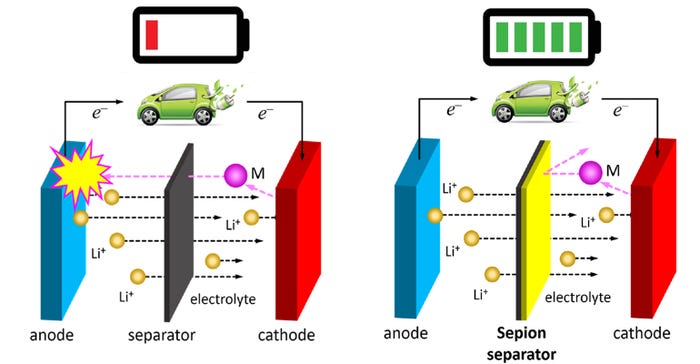

The procedure involves the application of a specialized coating onto the separator, a step that significantly enhances the battery's overall performance and characteristics. Sepion has pioneered the creation of a separator that incorporates a hybrid polymer-ceramic composite membrane coating layer that can prevent the growth of lithium dendrites on the lithium metal anode.

According to Sepion, its unique property sets this membrane apart – it allows the unrestricted flow of lithium ions while effectively obstructing the passage of electrolyte solvents. As a result, lithium metal batteries using these separator coatings have a higher energy storage capacity compared to current Li-ion batteries. Sepion's separator enables the use of liquid electrolytes, and it also has the potential to streamline the integration of lithium metal battery production with established Li-ion manufacturing methods.

Sepion’s new separator coating facility

This new facility, powered entirely by renewable energy and covering 25,000 square feet, amplifies Sepion's separator coating capacity by 1,000 and augments the polymer synthesis scale by 100. Furthermore, it facilitates manufacturing pouch cells with up to 10 Ah. These advancements will significantly accelerate Sepion's journey to shift its LMB separator coatings from the prototype stage to pilot-scale production, achieved through close collaboration with prominent automotive Original Equipment Manufacturers (OEMs).

“Today marks a major milestone in our journey to transform the EV landscape and sustainably power humankind,” stated Peter Frischmann, CEO and Co-Founder of Sepion Technologies. “We are proud to pioneer advancements that not only benefit the e-mobility industry but also contribute positively to our planet's well-being.”

The establishment of advanced separator coating facilities like Sepion's in North America represents a significant stride towards securing a sustainable and innovative future for the electric vehicle and renewable energy sectors. These facilities not only boost production capacity but also promote the development and adoption of cutting-edge battery technologies. As the demand for electric vehicles continues to rise, having such facilities in the region ensures greater energy independence, reduced environmental impact, and positions the US at the forefront of the global clean energy revolution.

About the Author(s)

You May Also Like