Altilium and Nissan Join Forces to Enhance UK EV Battery Sustainability

Discover the latest partnership from Altilium as they team up with Nissan to advance EV battery sustainability efforts in the UK.

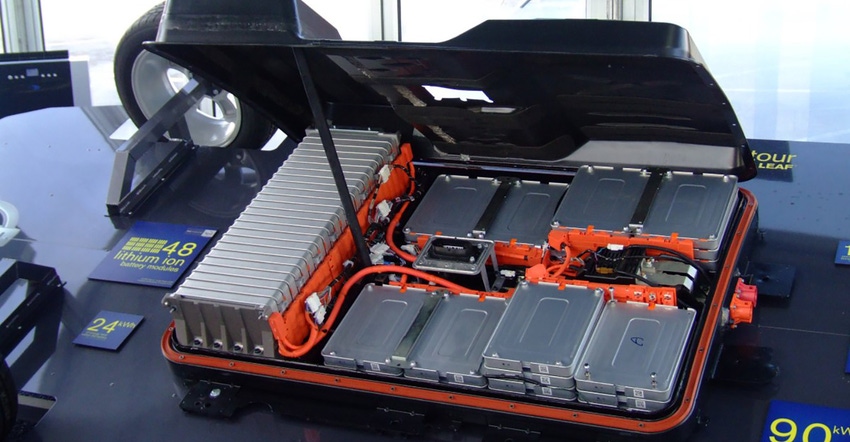

Altilium, a UK-based clean technology group, has announced a pioneering collaborative project with Nissan aimed at enhancing the sustainability of EV batteries manufactured in the UK and, at the same time, enhancing EV battery recycling efforts. With grant funding of £15M from the Advanced Propulsion Centre (APC), the project seeks to strengthen R&D capabilities at Nissan Technical Centre Europe (NTCE) in Cranfield, focusing on EV battery reuse, recycling, and energy balancing technology. The consortium also includes battery producer AESC and Connected Energy, a provider of second-life battery energy storage solutions.

Utilizing Altilium's green processing technologies, the project aims to establish a closed-loop model for battery materials, reducing reliance on mining and saving natural resources. Altilium claims its proprietary EcoCathod hydrometallurgical process can recover over 95% of cathode metals from end-of-life EV batteries, which are upcycled into high-nickel CAM, reducing the carbon footprint by 50% and cost by 20% compared to mined materials.

Dr Christian Marston, co-founder and COO of Altlium, stated: “The collaboration with Nissan, AESC and Connected Energy marks a significant milestone in our mission to create a sustainable ecosystem for EV batteries. Together, we are leveraging our strengths and resources to revolutionise how we manage and repurpose EV batteries, ensuring the UK has a domestic and sustainable source of battery materials for low carbon transportation.”

The collaborative effort, led by Nissan and Altilium, marks a pivotal moment for the UK battery supply chain. The initiative enhances resource efficiency and decreases reliance on imported raw materials through advanced recycling technologies and a closed-loop model. The UK can significantly reduce waste and carbon emissions by reusing and upcycling materials from end-of-life batteries while strengthening domestic capabilities in battery recycling and production. This bolsters supply chain resilience and fosters job creation and economic growth, particularly in regions like Teesside, where an industrial-scale recycling plant is planned. Moreover, the initiative underscores the importance of public-private partnerships in driving innovation and sustainability within the clean energy sector. Ultimately, it has the potential to position the UK as a leader in sustainable battery technology, supporting the country's transition to net zero emissions and driving progress towards a greener, more resilient future.

About the Author(s)

You May Also Like