Will China Outpace the West in Sustainability?

Discover China's leadership in sustainability in battery manufacturing and recycling, exemplified by CATL's Liyang plant and pioneering circular economy efforts.

China is emerging as a sustainability leader with pioneering initiatives in battery manufacturing and recycling. The following two advancements underscore China's commitment to sustainable practices, creating questions about its leadership in global sustainability initiatives.

Battery recycling study shows China is in 1st place

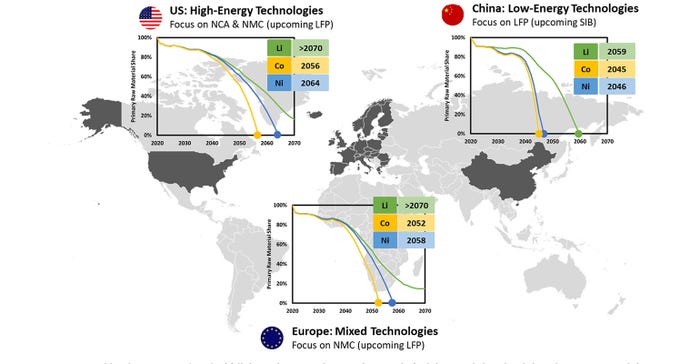

A recent study on battery recycling led by Prof. Stephan von Delft from the University of Münster reveals that China is expected to achieve a completely circular economy for primary lithium by recycling, starting as early as 2059, while Europe and the US are projected to reach this milestone after 2070. The timeline for cobalt sees China potentially meeting demand from recycling by 2045, compared to 2052 in Europe and 2056 in the US. Similarly, China aims for recycling-based self-sufficiency for nickel by 2046, with Europe following in 2058 and the US in 2064.

Forecasted break-even points (BEPs) of full demand coverage by secondary supply for lithium, cobalt and nickel in China, Europe, and the US. Courtesy of University of Munster / Elsevier.

The study emphasizes the importance of accelerated electrification in the automotive industry to speed up the availability of recyclable batteries. von Delft stated, “Our research shows that, in particular, a faster rate of electrification in the automotive industry, as is currently being discussed in the EU, will play a role in the process. The reason is that the faster electric vehicles spread throughout the automotive market, the sooner there will be sufficient quantities of batteries available for recycling.”

According to the report, reducing battery size and avoiding a "second life" for batteries could further expedite the equilibrium between the supply and demand for recycled raw materials. By leveraging recycling, China is anticipated to meet its demand for primary lithium by 2059, outpacing Europe and the US.

CATL's Liyang plant

CATL revealed that its facility in Liyang, located in Jiangsu Province, eastern China, has earned recognition as one of the 21 new additions to the Global Lighthouse Network (GLN) by the World Economic Forum (WEF).

CATL's Liyang plant in China is integrating sustainability in battery manufacturing. The company employed big data, additive manufacturing, computer vision, and deep learning to address rising demand and labor costs while aligning with carbon neutrality goals. According to CATL, the results include a 320% output increase, a 33% reduction in manufacturing costs, a 47.4% cut in normalized emissions, and an outstanding 99% drop in quality defects. Notably, the defect measurement has advanced from 'per million' to 'per billion.'

CATL's Liyang plant in east China's Jiangsu Province. Courtesy of CATL.

CATL's innovations cover faster capacity testing, quicker changeover times through virtual simulation and additive manufacturing, a comprehensive operation and maintenance system with the Industrial Internet of Things (IIoT) and big data modeling, more precise quality inspection using high-tech cameras and AI, and optimized sustainable energy management.

The plant's advancements exemplify how China contributes to the fight against climate change while applying these innovations across CATL's global network, demonstrating a commitment to sharing expertise and contributing to broader sustainable development goals.

China's strides underscore a commitment to sustainability surpassing conventional practices. While it's premature to declare China a leader in sustainability, these advancements in battery manufacturing and recycling distinctly highlight the nation's proactive and progressive stance in fostering environmentally responsible industrial practices.

About the Author(s)

You May Also Like