3D Printing Breakthroughs in Rechargeable Batteries

Explore the world of 3D printing technology and its impact on rechargeable batteries. Uncover the latest developments, challenges, and prospects in this groundbreaking field.

October 10, 2023

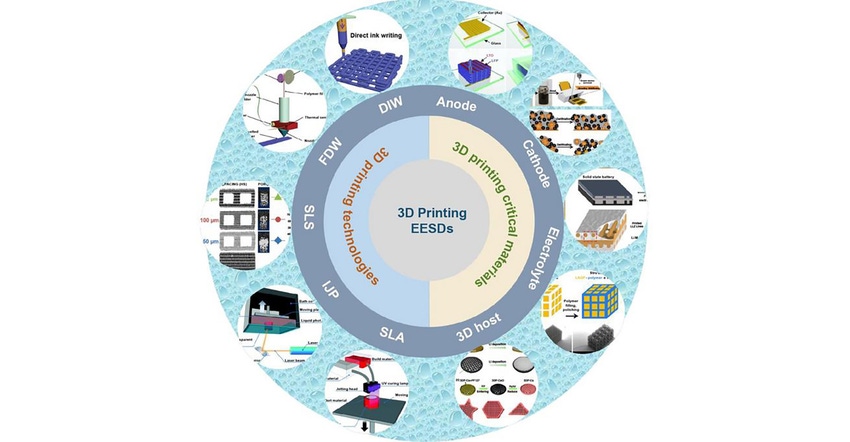

3D printing, as a promising additive manufacturing technology, is widely used in developing various electrochemical energy storage devices (EESD), such as batteries and supercapacitors at both nano and macro scale. This is due to its outstanding flexibility in manufacturing, capability in geometric design, cost-effectiveness, and eco-friendliness. Recent research has highlighted the excellent electrochemical performance of critical 3D printing materials in EESD due to their enhanced ion/electron transport capabilities and faster kinetics. Consequently, the 3D-printed EESD has higher energy density and rate capability.

Combining and developing new technologies and materials for emerging energy storage devices and equipment are crucial for rapidly advancing various EESD applications. However, recent comprehensive reviews of the structural design and applications of key 3D printing materials in EESD, especially rechargeable batteries, have been scarce.

In their recent research in the International Journal of Extreme Manufacturing, Prof. Lin Zeng’s group from the Southern University of Science and Technology presented the latest development in utilizing 3D printing technology for manufacturing various rechargeable batteries in this review. It outlines the typical characteristics of major 3D printing methods for fabricating electrochemical energy storage devices, including design principles, material selectivity, and optimization strategies.

The authors also discuss the crucial materials for 3D printing rechargeable batteries, including the anode electrode, cathode electrode, electrolyte, membrane, and 3D current collectors. It offers insights into the challenges and future research directions in developing crucial 3D printing materials for rechargeable batteries.

Prof. Zeng's team primarily engages in research and development related to fuel cells, electrolysis for hydrogen production, and materials and devices for electrochemical energy storage. Their work is based on studying the coupled mass transport phenomena at the electrolyte/electrode interface and electrochemical reaction kinetics.

“We have explored the mechanisms of cooperative mass transport, leading to a significant enhancement in the performance of electrochemical energy storage devices. In recent years, we have consistently produced research findings in various directions, including lithium-metal batteries, zinc-metal batteries, solid-state batteries, high-voltage cathodes, water electrolysis, and fuel cells.” Stated Prof. Zeng, whose group has made significant contributions in the field of 3D-printed secondary batteries, such as 3D-printed composite zinc anodes and 3D-printed solid-state electrolyte membranes.

The challenges of 3D printing

While 3D printing offers numerous advantages and tremendous potential in the field of EESD, several obstacles and challenges still need to be addressed to develop 3D printing technology further and promote its practical applications.

For example, first, to enhance the capabilities of 3D printing for EESD, it's crucial to break down the functions of 3D printing equipment, improve each subsystem, and develop integrated printing platforms. Second, research on multifunctional additives for 3D printing of rechargeable batteries is necessary to fine-tune the rheology of inks and optimize electrochemical performance. In addition, selecting the best manufacturing methods, process parameters, and structural parameters significantly impacts the capacity and power of the battery. Meanwhile, a comprehensive understanding of the interaction between electrochemical performance and structural design is necessary to optimize battery performance.

“Despite the challenges and drawbacks in developing 3D-printed rechargeable batteries, we believe that by continually advancing efficient, cost-effective, high-performance, and diverse 3D printing technologies, 3D printing will become an indispensable part of future manufacturing, bridging the gap between industry and basic research,” stated Prof. Zeng, the Deputy Director of the Carbon Neutrality Research Institute.

“To advance the commercial applications, some factors need to be considered for practical production, such as manufacturing cost, uniformity of product (including structural stabilities and performance stabilities), and potential application scenario and market sizes. Among many factors, the costs of 3D printed equipment and printable materials are the key to commercial application; factors such as premises and staff cannot be ignored. The safety performance of the final products for power batteries should be significantly improved to show attractive technical advantages and commercial values, especially under high energy densities and reduced manufacturing cost,” concluded Zeng.

About the Author(s)

You May Also Like