Battery Recycling Pilot Programs Compete for Millions

A DOE competition is in its third phase, providing up to $5.5 million to seven teams to demonstrate the feasibility of their lithium-ion battery recycling pilot programs.

March 6, 2021

One thing electric vehicle (EV) naysayers love to claim is that the lithium-ion batteries that are destined to power our electrified transportation system either can’t be or won’t be recycled. This claim is absurd, as lithium-ion cells are already being recycled in pilot plants created by car companies and their industrial partners around the world. Want more proof? Consider the Lithium-Ion Battery Recycling Prize of the U.S. Department of Energy (DOE) Office of Energy Efficiency and Renewable Energy.

The Prize

The Prize was announced in January 2019 and recently launched its third and final phase aiming toward DOE’s goal to capture 90% of all spent lithium-ion batteries for eventual recycling of critical materials and reintroduction into the supply chain.

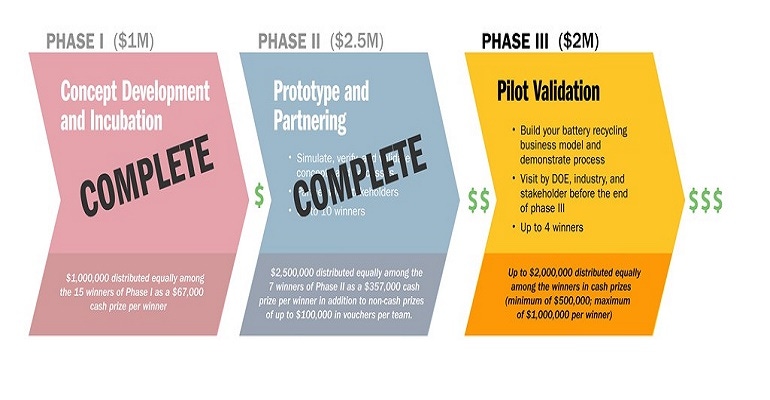

The phased prize competition is designed to help find innovative solutions to collecting, storing, and transporting discarded lithium-ion batteries for eventual recycling. In Phase I, called Concept and Incubation, $1 million was distributed among 15 winners as $67,000 cash prizes per winner. In Phase II, Prototyping and Partnering, $2.5 million in prize money was distributed between the seven winners, each receiving $357,000. In Phase III, called Pilot Validation, the seven winning teams from Phase II will demonstrate their ability to recover lithium-ion batteries and verify the feasibility and scalability of their pilot projects. Teams received up to $100,000 in vouchers to partner with industry experts and DOE’s National Laboratories through the American-Made Challenge Network to support their pilot validation.

“Lithium-ion batteries are becoming more and more prevalent, from cell phones and laptops to increasing numbers of electric vehicles on the road,” said Lauren Lynch, prize administrator in an NREL news release. “It is important to implement effective processes to recover the critical materials and avoid potentially negative impacts, environmental or otherwise.”

The Competitors

The seven Phase II winning teams that will participate in Phase III are:

Li Industries (Blacksburg, Virginia)Li Industries is developing a machine-learning-based, automated Smart Battery Sorting System capable of accurately and efficiently sorting and separating batteries by several characteristics, including chemical composition, size, weight, and packaging type.

OnTo Technology (Bend, Oregon)OnTo’s deactivate, identify, sort, and cut solution provides safe and efficient end-of-life processing of waste batteries by sorting LIBs by cathode chemistry.

Powering the Future (Glendale, Wisconsin)Clarios is leveraging the existing network of collection for lead-acid batteries to collect end-of-life (EOL) LIBs, applying innovative technologies to handle mixed EOL batteries and ultimately optimize the network’s value.

Renewance (Chicago, Illinois)The Renewance Connect asset tracking and marketplace concept optimizes reverse logistics and recycling activities by improving access to and utilizing existing infrastructure for decommissioning, collection, warehousing, sorting, transportation, and recycling services.

Smartville (San Diego, California)Smartville is deploying distributed heterogeneous unifying battery (HUB) facilities to reduce costs and create value in the reverse-logistics supply chain by balancing, conditioning, and certifying LIBs before repurposing for secondary use or shipped to recyclers.

Team Portables (Seattle, Washington)Reward to Recycle is a consumer engagement smartphone app allowing consumers to learn how to earn a reward for recycling their battery. This app uses a digital identity to track portable LIBs and support final recycling.

Titan Advanced Energy Solutions (Somerville, Massachusetts)The Battago platform will generate, aggregate, and connect battery data to create a transparent marketplace and bridge the gap between battery owners, integrators, and end-of-life recyclers.

Viability

According to a DOE release, “In Phase III of the Prize, the teams must substantially advance their end-to-end solutions and provide pilot validation of their concepts. Teams will incorporate impact modeling from Phase II to demonstrate the feasibility of their solutions. Progress made in Phase III will demonstrate how effective, efficient, and viable their concepts are when fully scaled.”

Each Phase III participating team can use up to $100,000 in non-cash vouchers to further the development of its project. NREL researchers will join other national laboratories and industry experts, providing support to participating teams to assist in developing, testing, and validating their solutions. These prize vouchers allow teams to access tools, equipment, and expertise to advance their concepts. Up to four final winners of Phase III will be selected and winners will receive a cash prize of up to $2,000,000, distributed equally among the winning teams.

We All Win

One reason why lithium-ion batteries aren’t recycled at higher rates is the small number of EVs (only around 2% of new vehicle sales) in the market, and how relatively new they are. As the electrification of transportation takes hold in the second part of this decade and EVs begin to age out, the numbers of lithium-ion batteries available for recycling will grow quickly. The object of the DOE Battery Recycling Prize is to be ready and able to meet those recycling needs, making us all the winners, and contrary to what anti-EV forces would have you believe.

Kevin Clemens is an engineering consultant who has worked on automotive and environmental projects for more than 40 years.

About the Author(s)

You May Also Like