New Battery Facilities Almost Ready for Production

SES AI and Microvast are each making their final moves toward production at their newest manufacturing sites.

This month, two battery makers have announced that they are each in the final steps of preparation before embarking on the production of battery cells at new manufacturing facilities. SES AI Corp. is perfecting its new Line 4 manufacturing line in Boston while Microvast is bringing in equipment and hiring talent for its just-built Clarksville, TN facility. Here are the details.

SES: Line 4 is a pivotal phase for lithium-metal cell production

Boston-based SES AI Corp., a prominent lithium-metal (Li-Metal) rechargeable battery developer for electric vehicles (EVs) and other applications, has announced the commencement of preparations for ‘Line 4.’ This new manufacturing line will mark the company's most advanced and pivotal phase in Li-Metal cell production, succeeding the establishment of three A-sample lines in Shanghai, China, and two in Cheongchungbuk-do, South Korea, which were completed last year.

“We have accumulated tremendous learning from our three A-sample lines, we are combining all these learnings into a brand-new line, our Line 4,” stated SES AI founder and CEO Qichao Hu.

Hu emphasized that Line 4 will exhibit significantly enhanced processes, quality, yields, and operational efficiency compared to the A-sample lines. This new line will seamlessly integrate with the Avatar system, facilitating the seamless collection and transmission of manufacturing data to the company's AI battery health monitoring software. Not all details regarding the advanced processes will be disclosed by SES. Currently, the company is actively engaged in design reviews and has commenced issuing purchase orders (POs). Hu anticipates the completion of the dry rooms by this summer, equipment delivery commencing in the fall, and the line becoming fully operational and ready for use in the first half of 2024.

“Line 4 will be a major milestone for the automotive commercialization of Li-Metal cells,” Hu finished.

Microvast: Equipment and new hires coming to Clarksville

Microvast Holdings Inc., a developer of lithium-ion batteries, is in the home stretch of renovations and hiring for its newest manufacturing plant located in Clarksville, TN.

“From major building renovations to the hiring of veterans and other high-caliber local talent, the Clarksville facility is poised to play a significant role in delivering battery manufacturing to the US while also adding a boost to the local economy here in Montgomery County,” stated Shane Smith, Microvast’s Chief Operating Officer.

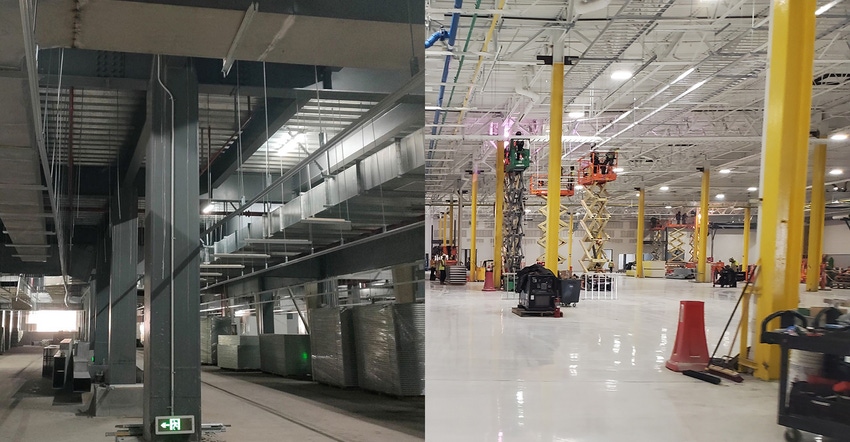

Smith continued, “Inside Microvast’s manufacturing plant, drastic changes are taking place as we quickly transition from construction to installation of the battery manufacturing equipment. There is still a lot to do, but we remain on track.”

The Clarksville facility focuses on the manufacturing of Microvast’s high-performance 53.5-Ah battery cells and modules used in commercial vehicles and energy storage systems. The renovated plant, expanded from 577,000 to 687,000 sq. ft., is expected to support every stage of the production process, from cell manufacturing through pack assembly. The renovation also includes multiple environmental tests, the creation of environmentally controlled, contaminant-free dry rooms, and a brand-new quality lab with state-of-the-art testing equipment to help ensure quality and safety.

“The construction at the Clarksville facility is progressing as planned and we expect to begin production in Q4 2023,” stated Smith.

Along with the renovation progress, Microvast has also ramped up hiring ahead of its anticipated Q4 2023 production start, taking part in several successful recruiting events as it seeks to fill numerous positions. With such close proximity to Fort Campbell, the company has been particularly focused on adding the talents and skills of local veterans and their spouses to the Microvast team. Potential positions include quality technicians, quality engineers, operations supervisors, and more.

About the Author(s)

You May Also Like