Solutions for Continuous Manufacturing of Battery Materials

Coperion and Coperion K-Tron will showcase their solutions for the continuous production of battery masses at The Battery Show North America 2023.

With the growing demand for batteries in various industries, advancements in battery mass production technologies are continually evolving to improve efficiency, reduce costs, and enhance the overall quality of batteries. The production of battery masses is a critical step in battery manufacturing, as the quality and consistency of these materials directly impact the performance and reliability of the resulting batteries.

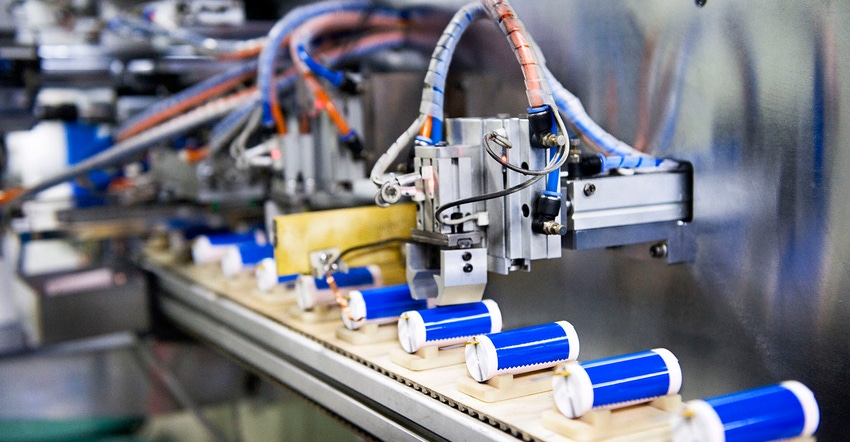

Coperion and Coperion K-Tron are set to showcase their cutting-edge technologies and comprehensive solutions for the continuous manufacturing of battery materials at Battery Show North America. Coperion's conveying systems and Coperion K-Tron's feeders provide a solution to secure material transport and high-precision ingredient feeding.

Safe conveying and feeding for processing active material and black mass recycling

Safe conveying and feeding for processing active material and black mass recycling in battery manufacturing or recycling involves handling potentially hazardous materials while ensuring worker safety and environmental compliance.

The correct processing of active materials is a crucial factor in producing battery compounds. Given that the active material is primarily responsible for storing energy within the battery, the meticulous manufacturing of this substance is imperative for achieving top-tier product quality. The production of the active material involves a multi-step process that hinges on the safe handling and precise feeding of bulk materials and additives.

This is particularly relevant when it comes to the recycling of black mass. Given the utilization of hazardous components in producing active cathode materials and recycling black mass, the need for secure containment cannot be overstated. Coperion K-Tron feeders can be used to introduce materials into the process safely. They achieve this through weighing and control technology, ensuring the production of active materials under protective conditions while upholding a strict quality standard.

Twin screw extruders and loss-in-weight (LIW) feeders

Twin screw extruders and loss-in-weight (LIW) feeders are essential components related to battery compound production in semi-dry and dry processes. Twin screw extruders are machines for mixing, compounding, and processing materials. LIW feeders are devices used for precise and continuous feeding of materials into a process based on weight control. They are crucial for maintaining accurate ingredient ratios and provide battery manufacturers with a highly efficient production method.

Coperion offers the ZSK Mc18 twin screw extruder, a solution for quality and throughput in battery compound production. Due to the extruder’s high torque, both semi-dry and dry processes can be realized using this manufacturing process. The individual process sections within the extruder allow for the mixing of dry masses, thus smoothing the path toward future forms of processing. Coperion claims that in comprehensive tests, battery compounds have been successfully manufactured on Coperion extruders using Coperion K-Tron feeders in semi-dry and dry processes.

Coperion offers solutions for recipe development, leveraging the capabilities of the ZSK 18 MEGAlab and ZSK 26 Mc18 twin screw extruders. These laboratory and small-series extruders are purpose-built to meet rigorous research and recipe development requirements. They are well-suited for experimenting with new, enhanced, or modified recipes and their subsequent validation.

About the Author(s)

You May Also Like