Want to Improve EV Battery Behavior? Give It a Rest

Stanford researchers say you can improve your lithium-metal EV battery’s health and behavior the same way you would improve your toddler’s: By enforcing nap time.

Stanford University researchers have discovered a surprisingly simple yet effective solution to enhance the cycle life of lithium metal batteries, potentially revolutionizing the electric vehicle (EV) industry. Lithium metal batteries offer a game-changing 500 to 700 miles on a single charge, double the range of conventional lithium-ion batteries. However, these batteries suffer from rapid capacity loss after a limited number of charging cycles, making them impractical for long-term use.

The breakthrough, outlined in a recent study published in the journal Nature, involves treating your overtired battery as you would an overtired toddler: Give it a rest.

By draining the battery and allowing it to rest for several hours in a discharged state, researchers found that lost capacity could be recovered and overall performance significantly improved. This straightforward technique requires reprogramming the battery management software, with no additional cost or changes needed in equipment, materials, or production flow.

Resting battery face

Lead author Wenbo Zhang, a Stanford PhD student in materials science and engineering, explained in a Stanford news release, "We were looking for the easiest, cheapest, and fastest way to improve lithium metal cycling life." The study offers practical insights for EV manufacturers aiming to adapt lithium metal technology to real-world driving conditions.

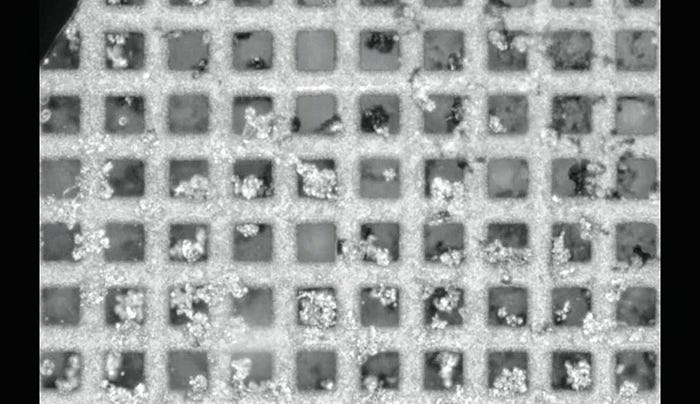

Magnified image of a copper mesh from a lithium metal battery in the discharged state. Tiny pieces of dead lithium of various sizes and shapes are deposited on square openings in the mesh. (Image credit: Wenbo Zhang/Stanford University)

Lithium metal batteries, which replace the graphite anode with electroplated lithium metal, can store twice the energy of lithium-ion batteries in the same space, offering EVs double the range. The drawback lies in the rapid degradation caused by continuous charging and discharging, resulting in the isolation of micron-sized lithium metal bits, rendering the battery ineffective for routine driving.

The researchers discovered that allowing the battery to rest for as little as one hour in a discharged state dissolves the solid electrolyte interphase (SEI) matrix, allowing dead lithium to reconnect with the anode during recharge. This simple method rejuvenates the battery, recovering lost capacity and extending its cycle life.

The rest is history

The practicality of this approach is emphasized, considering that the average American driver spends about an hour behind the wheel each day. The existing battery management system in EVs can be programmed to discharge individual modules, offering a cost-effective solution without the need for new manufacturing techniques or materials.

The Stanford study provides a potentially transformative solution for the widespread adoption of lithium metal batteries in the EV industry, offering drivers extended range without the anxiety of rapid degradation. And no milk and cookies are required.

About the Author(s)

You May Also Like