Argonne Scientist Shirley Meng Recognized for Battery Science Work

Materials science pioneer Meng receives The Electrochemical Society’s 2023 Battery Division Research Award for innovative energy storage research.

July 19, 2023

The Electrochemical Society (ECS) has selected scientist Shirley Meng of the US Department of Energy’s (DOE) Argonne National Laboratory as the recipient of the 2023 Battery Division Research Award for innovative research on interfacial science, which has led to improved battery technologies.

A pioneer in discovering and designing better materials for energy storage, Meng serves as chief scientist of the Argonne Collaborative Center for Energy Storage Science (ACCESS) and as a professor at the Pritzker School of Molecular Engineering at The University of Chicago. Her research focuses primarily on energy storage materials and systems, specifically rechargeable batteries for electric vehicles and trucks, power sources for the Internet of Things, and grid-scale storage to facilitate the widespread integration of renewable energy sources. Meng will be formally recognized in October at the 244th ECS Meeting in Gothenburg, Sweden.

“I’m deeply honored to have my work recognized by ECS. This award not only acknowledges my contributions but also highlights the interdisciplinary research conducted by the Laboratory for Energy Storage and Conversion team in addressing global energy challenges,” Meng said. “I’m grateful for the support of DOE, Argonne, and my colleagues at both the Sustainable Power & Energy Center and at the Pritzker School of Molecular Engineering. Together, we are pushing the boundaries of knowledge and paving the way for a sustainable energy future.”

Interfacial science investigates the chemical, physical, and electrochemical processes that occur where the electrode and electrolyte meet in a battery (the interface). It examines phenomena such as charge transfer, ion transport, interfacial reactions and the formation of protective layers or interfacial films. The goal is to optimize the interactions between the different materials and components to enhance battery performance, stability, and lifespan.

The Battery Division Research Award was established in 1958 to encourage excellence in battery and fuel cell research. Meng is being honored with this year’s award for what ECS described as “innovative and original research” reflected in her publications, specifically two papers published last year in the Journal of The Electrochemical Society (JES).

Putting dendrites under pressure

The first paper explored the use of external mechanical pressure to regulate the growth of needle-like structures known as dendrites that form at the interfaces in batteries and lead to an electrical short.

To address this, Meng and her colleagues designed a pressure control apparatus for lithium metal batteries that can use either liquid or solid-state electrolytes. The setup included a split cell and a pressure load cell for precise pressure control.

When a lithium metal battery cell charges, lithium ions move from the cathode (the positive side) through the electrolyte to the anode (the negative side). The anode expands as lithium atoms are deposited on its surface. During discharge, the anode contracts as lithium is stripped away. This back-and-forth process is normal in rechargeable batteries. The researchers demonstrated the effectiveness of their setup by studying the pressure’s impact on the lithium plating and stripping process, and the electrochemical reactions that occur during the charging and discharging of the battery.

Overall, the research highlights the importance of carefully controlling pressure to optimize the cycling behavior of lithium metal anodes, which are key for developing next-generation high energy density batteries. The paper is an Editor’s Choice piece in JES.

Lithium plating and stripping

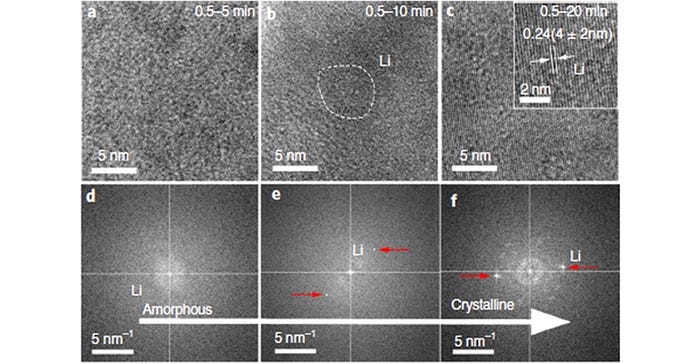

The second paper is a perspective focusing on understanding the process of lithium plating and stripping in rechargeable lithium batteries. Meng and her colleagues investigated the formation and growth of lithium deposits at different length scales, ranging from the atomic level to the microscale.

The team used advanced imaging techniques and computer simulations to study the behavior of lithium during the plating or deposition process. They discovered that lithium starts off in an amorphous/disordered state and then changes into a crystalline structure. The speed of the process was found to play a significant role in the formation and shape of the lithium deposits.

Their findings suggest that achieving reversible and efficient dense lithium plating and stripping is crucial for the long-term performance of rechargeable lithium batteries.

Meng’s award research was supported by DOE’s Vehicle Technologies Office.

About the Author(s)

You May Also Like