Solvionic: What You Need to Know about Liquid Electrolytes & Safety

Learn from Solvionic's assessment of safe electrolytes, optimizing battery performance and safety across different configurations for next-generation energy storage solutions.

Liquid electrolytes are foundational to battery technology, serving as conductive mediums for ion transfer between electrodes, essential for energy storage. A white paper by Solvionic titled “ Safe electrolytes for high voltage lithium batteries” delves into the critical role of non-flammable liquid electrolytes in batteries, examining their impact on performance metrics such as energy density, cycle life, and safety. By discussing innovations in electrolyte formulation, additives, and electrolyte-electrode interactions, the white paper provides insights into the evolving landscape of battery electrolytes. Its comprehensive analysis of research findings aims to contribute to developing next-generation battery systems with improved performance, reliability, and safety profiles. We’ll summarize those findings here; the entire white paper can be found at [link].

The role of liquid electrolytes

According to Solvionic, liquid electrolytes are crucial in advancing battery technology for several reasons. Firstly, they enhance safety by mitigating the risk of thermal runaway and fire hazards associated with flammable electrolytes, making them particularly valuable for applications prioritizing safety, such as electric vehicles (EVs) and portable electronics. Additionally, liquid electrolytes often demonstrate superior chemical and thermal stability, leading to extended battery cycle life by minimizing electrolyte degradation and side reactions, thereby improving long-term performance and reliability.

Furthermore, they enable the utilization of higher voltage and energy-dense electrode materials without compromising safety, resulting in batteries with increased energy densities. This enhances runtime and power capabilities, which are essential for applications requiring high energy storage capacities. The company claims that non-flammable electrolytes are also compatible with a wide range of electrode materials and battery chemistries, offering flexibility in battery design and facilitating the development of next-generation battery technologies with improved performance characteristics.

Solvionic’s assessment

Solvionic compared LNMO (Li₁Ni₀.₅Mn₁.₅O₄) cathodes—TOPSOE’s cathode material—paired with graphite and lithium metal anodes to evaluate the performance and suitability of each configuration for advanced lithium-ion battery systems. By comparing these two setups, Solvionic aimed to assess the performance and suitability of their non-flammable electrolytes—Solviolyte—in various battery configurations.

Full cell LNMO - Graphite at 25°C and 45°C

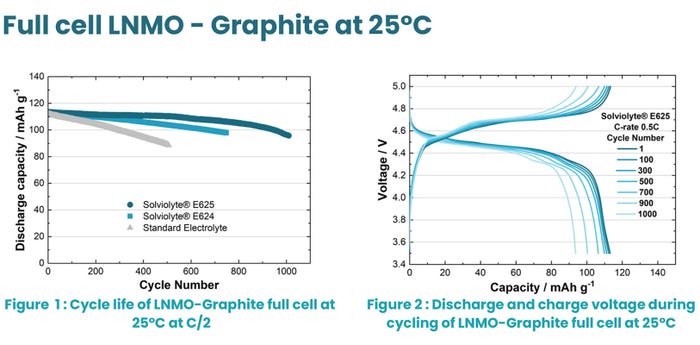

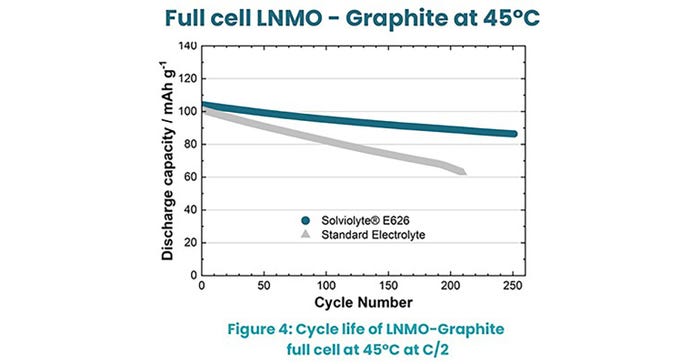

The company assessed its non-flammable electrolyte in various battery configurations. Firstly, they tested full cell LNMO - Graphite batteries at 25°C and 45°C, demonstrating significantly improved capacity retention with Solviolyte E625 compared to standard electrolytes.

Full cell NMO - Graphite at 25°C. Courtesy of Solvionic.

At 25°C, 90% capacity retention was achieved after 900 cycles, compared to only 279 cycles with standard electrolytes. The efficiency of Li⁺ ion diffusion and charge/discharge reversibility was also highlighted, with a mere 15% capacity loss at higher discharge rates. Similarly, at 45°C, Solviolyte exhibited significantly lower capacity loss than standard electrolytes after 250 cycles.

Full cell NMO - Graphite at 45°C. Courtesy of Solvionic.

Full cell LNMO - Li Metal at 25°C

Furthermore, Solviolyte assessed full cell LNMO - Li Metal batteries at 25°C, showcasing the stability of their electrolytes with over 94% capacity retention after 700 cycles at 100% Depth of Discharge (DoD). Solvionic emphasized their cycling stability, surpassing carbonate-based electrolytes.

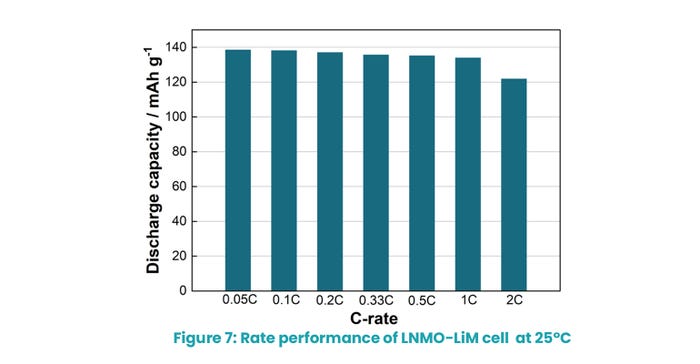

Their findings also demonstrated the advantage of utilizing lithium metal anodes over graphite, particularly at higher discharge rates, with a discharge capacity exceeding 120mAh.g⁻¹ at 2C, representing only a 10% reduction compared to 1C. In contrast, graphite anodes showed a significantly higher capacity loss between 1C and 2C.

LNMO - Li Metal batteries at 25°C. Courtesy of Solvionic.

Understanding the differences between LNMO - Graphite and LNMO - Lithium metal systems helps optimize battery designs and identify the most effective combination of cathode and anode materials. Additionally, this comparison allows Solvionic to evaluate safety considerations associated with each anode material and develop strategies to enhance the safety and performance of next-generation lithium-ion batteries for various applications.

Solvionics' assessment showed that using non-flammable electrolytes positively influenced the results by enhancing battery performance, safety, and stability. These electrolytes facilitated efficient ion transport, improving charge/discharge reversibility and reducing capacity loss over cycling. Non-flammable electrolytes have the potential to deliver natural and superior chemical and thermal stability, mitigating the risk of thermal runaway and electrolyte degradation and contributing to overall battery reliability.

About the Author(s)

You May Also Like