At 6K Energy, Environmentally Friendly Battery Materials Processing is Hot

A 6,000-degree Kelvin microwave plasma system enables faster, cleaner production. Company president Sam Trinch explains.

Shamara Ray, Group Event Director, The Battery Show

The ability to create battery materials and processes that fit into low-cost, higher-power requirements is difficult and often environmentally unfriendly and unsustainable. With power and energy requirements in constant flux within the energy storage market, combined with the industry's highly complex and technical nature, integrating sustainable practices into the manufacturing process is incredibly challenging.

6K Energy, an industry-leading division focused on producing low-cost, environmentally friendly battery materials, is championing the innovative process of plasma technology to not only lower the environmental impact of global battery material production but to do so cost-effectively and sustainably.

I had the pleasure of speaking with Sam Trinch, president of 6K Energy, a prominent exhibitor at The Battery Show North America, about the current challenges and opportunities in the energy storage market and what attendees can expect to learn at their booth this September 13-15 at the Suburban Collection Showplace in Novi, Michigan.

The Battery Show North America, co-located with The Electric & Hybrid Vehicle Technology Expo, serves as North America's largest and most comprehensive advanced battery technology event bringing together industry-leading engineers and business leaders to discover and demo the latest products, technology, and solutions from more than 750 suppliers.

What are the current challenges in the energy storage market?

Trinch: The move toward vehicle electrification is causing an increased demand for batteries and battery material production. The current hydrometallurgical process for producing battery material is expensive and much harder on the environment than many people know; because of these critical factors, China controls 85% of global battery material production. By contrast, the United States today produces zero battery material for production. Bringing the current process to US soil or EU soil for domestic production of battery material would be costly and have a devastating effect on the environment based on the stated Li-ion capacity expansion.

How is 6K Energy addressing these obstacles?

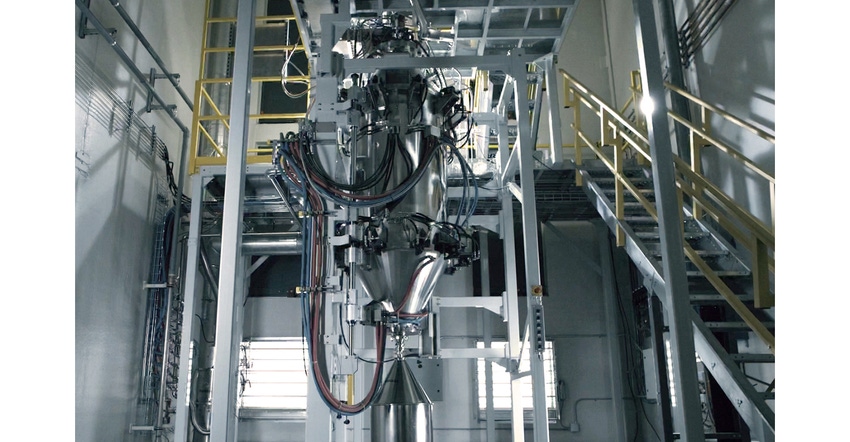

Trinch: 6K Energy has developed an innovative process to produce battery material that leapfrogs legacy battery material processing technology with proven 6,000-degree Kelvin microwave plasma technology, known as UniMelt. 6K’s UniMelt process can produce multiple chemistries ultra-fast and at substantially lower cost with significantly less environmental impact than the current process. 6K’s UniMelt can produce battery material using 90% less water, generating zero solid and liquid waste and significantly less energy and CO2 emissions.

The capital cost for setting up a battery material production plant with the UniMelt technology is 20-30% less than the current process while occupying half the total footprint, allowing for smaller, modular facilities to be built locally. The modularity and flexibility of a UniMelt plant will allow for the start of production ramp-up ahead of full capacity installation, making it capable of producing battery material sooner and more efficiently. Lastly, the equipment developed out of the MIT Plasma Science and Fusion Center can be redeployed when you want to change chemistries, making it virtually futureproof. The end result is auto manufacturers that utilize 6K Energy battery material can save billions with a significantly reduced environmental impact.

What can you tell us about the future of Plasma Technology?

Trinch: The UniMelt process is based on a patented microwave plasma technology that provides for a very controlled, uniform, highly reactive, and high-temperature reaction zone that enables the synthesis of materials at rates far greater than with conventional methods and with much greater chemistry and size flexibility. This flexibility in the chemistry allows for a simple transition from one chemistry to another, easily adapting to the rapidly changing chemistry landscape for battery material. Expanding the plasma production zone through engineering advancements provides a future path for higher-throughput and more cost-effective solutions.

6K Energy has partnered with Cirba Solutions (formerly Retriev) to produce new battery material from recycled EOL batteries, developing a solution to the critical supply needs of raw battery material at a low environmental and economic cost. By working together, we can reduce the cost and energy needed in the process by eliminating the need to separate metals and process to dry powder. Using a mixed metal oxide solution, we can test, concentrate, and process directly into new battery materials with the same quality and performance without having to mine virgin metals and rely on China for processing.

What advancements is 6K Energy currently making in the automotive applications industry, including EVs?

Trinch: Just over a year ago we announced our Battery Center of Excellence (BCE) and we are weeks away from opening its doors. The new state-of-the-art facility will accommodate up to ten UniMelt systems that can produce as much as 100 tons of material from each system annually. This will support full scale development of materials such as high energy density and single crystal cathode, solid-state electrolyte materials, silicon anode for fast-charging and many more. The expansion will create 6K Energy pilot production capabilities to fully support partner qualification, providing a gateway direct to domestic production.

The BCE will also allow us to offer dedicated UniMelt systems to customers, enabling the rapid commercialization of battery materials, which could have major implications for the cycle life and safety of future NMC-based EV products, making smaller, lower cost batteries a reality, without giving up vehicle range. Our recent announcements with companies like Albermarle and ONE are two great examples of how the BCE will jointly help 6K Energy and our partners advance battery materials production.

You’re a prominent exhibitor at The Battery Show North America. What products and technologies can attendees look forward to learning about at your booth?

Trinch: 6K Energy will showcase its full portfolio of cathode, anode, and solid-state electrolyte materials produced with the UniMelt process. A demonstration of the UniMelt microwave plasma technology will be on display in our booth, with the complete process outlined and described. The 6K Energy team can walk you through the current process and the future plans for battery material development.

The electric industry is growing like crazy, and 6K Energy has a proven, cost-effective solution to deploy a battery material production plant at scale that can produce multiple chemistries under one roof at a fraction of the cost with significantly less impact on the environment.

About the Author(s)

You May Also Like