Building Better Cathodes Without Cobalt

Another step in the continuing effort to remove expensive and politically sensitive cobalt from lithium-ion battery cathodes.

February 5, 2021

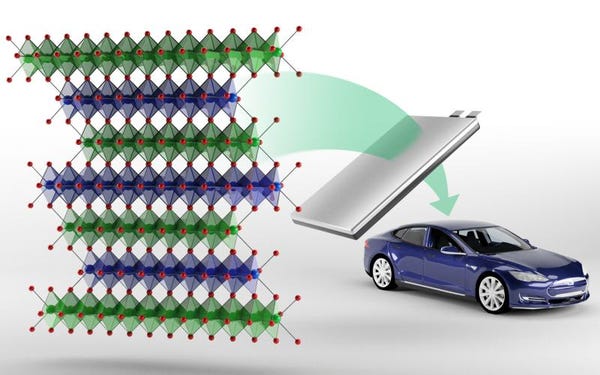

As electric vehicles (EV) are finally beginning to reach acceptance the raw materials that are used to build their lithium-ion batteries are coming under closer scrutiny. Lithium itself isn’t particularly scarce or expensive, but the nickel-based oxide that is used for the battery cathode (positive electrode) is costly, made even more so by the addition of cobalt. Cobalt is used to help stabilize the structure of the nickel-based cathode, maintaining the structural integrity as lithium ions move in and out of the cathode during the charging and discharging of the battery.

Cobalt is not only scarce and therefore expensive, but its primary source is also the Democratic Republic of the Congo (DRC), a country that suffers from political instability and unethical mining practices. The challenge is to find ways to make highly energy-dense cathodes for lithium-ion batteries that eliminate the need for cobalt.

ORNL's New Cathode Family

Recently, Oak Ridge National Laboratory (ORNL) researchers have developed a new family of cathodes with the potential to replace the cobalt-based cathodes found in today’s lithium-ion batteries that power electric vehicles and consumer electronics such as laptops and cellphones.

The new class is called NFA, which stands for a nickel, iron, and aluminum-based cathode. It is a derivative of lithium nickelate and can be used to make the positive electrode of a lithium-ion battery. Lithium nickelate is interesting as a positive electrode material for lithium-ion batteries because of its large capacity at ambient temperatures, but it can demonstrate undesirable exothermal reactions and instability at higher temperatures.

“Lithium nickelate has long been researched as the material of choice for making cathodes, but it suffers from intrinsic structural and electrochemical instabilities,” according to Ilias Belharouak, ORNL’s scientist leading the NFA research and development in an ORNL press release. “In our research, we replaced some of the nickel with iron and aluminum to enhance the cathode’s stability. Iron and aluminum are cost-effective, sustainable, and environmentally friendly materials.”

Fast, Dense, Cost-Effective

The novel cathodes designed by ORNL are fast charging, energy-dense, cost-effective, and longer-lasting. “Our investigations into the charging and discharging behavior of NFA showed that these cathodes undergo similar electrochemical reactions as cobalt-based cathodes and deliver high enough specific capacities to meet the battery energy density demands,” said Belharouak.

Although research on the NFA class is in the early stages, Belharouak said that his team’s preliminary results to date indicate that cobalt may not be needed for next-generation lithium-ion batteries. “We are developing a cathode that has similar or better electrochemical characteristics than cobalt-based cathodes while utilizing lower-cost raw materials,” he said.

In addition to performing as well as cobalt-based cathodes, the NFA cathodes investigated by Belharouak and his ORNL team can be integrated into existing global cathode manufacturing processes. That means not only are special manufacturing equipment and techniques not required, but also the adoption of the cobalt-free NFA cathode can occur quickly as larger-scale lab results prove the suitability for the cathodes in applications like EVs.

Kevin Clemens is an engineering consultant who has worked on automotive and environmental projects for more than 40 years.

About the Author(s)

You May Also Like