June 6, 2023

As industries across the world are searching for battery-powered devices with greater performance and sustainability, one thing has become clear: lithium-ion batteries need to go. In place of lithium-ion batteries, the industry has been turning its attention to a number of other battery chemistries. Amongst these lithium-ion alternatives, lithium-sulfur (Li-S) batteries are of particular interest.

Describing the benefits of lithium-sulfur batteries over lithium-ion batteries in a recent interview with Battery Technology, Conamix CEO Charlotte Hamilton explained that lithium-sulfur batteries have a greater volumetric energy density than lithium-ion batteries, as well as greater sustainability by not requiring materials like nickel, cobalt, and manganese. Recognizing these benefits, many people have begun development on Li-S solutions, such as the recent German project MaSSiF which aims to produce high-capacity sulfur-based battery prototypes.

Now, the Li-S industry seems to be keeping its momentum going with another slew of noteworthy recent news headlines. Read on to learn about some of the most exciting news in the lithium-sulfur battery field.

Stellantis’ Lithium-Sulfur Investment

At the end of last month, Stellantis made headlines when they announced an investment into Lyten, a developer of sulfur battery technologies.

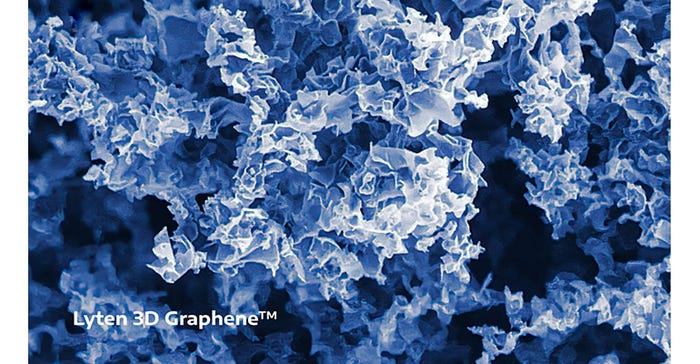

Lyten is most well-known for its work in tunable three-dimensional graphene but is also highly revered for its LytCell Lithium-Sulfur EV batteries. According to Lyten, their LytCell solution offers an EV battery with a 60% weight reduction and 2x the energy density of conventional lithium-ion EV batteries, while also offering material sustainability benefits. These benefits translate into EVs that are more energy-efficient, sustainable, and have greater range than what currently exists on the market.

By investing in Lyten, Stellantis hopes to accelerate the commercialization of Lyten's applications in the mobility industry with the ultimate goal of leveraging the company’s technology in their future fleets of EVs.

Li-S Energy’s Breakthrough

In other lithium-sulfur news, Australian company Li-S Energy recently announced a breakthrough in their lithium-sulfur battery technology.

Specifically, Li-S Energy claims to have successfully created its first 20-layer battery cells utilizing which were created via semi-solid state lithium-sulfur battery technology. With the achievement of this feat, Li-S Energy’s new battery cells are said to offer a 45% improvement in volumetric energy density as compared to lithium-ion batteries (reaching values up to 540Wh/l) as well as a gravimetric energy density of up to 400Wh/kg.

The company claims that, as compared to current Li-ion cells, their new Li-S solution has double the gravimetric energy density. The result is that, if used in EVs, their batteries can result in lightweight vehicles with greater range. The company plans to begin production of commercial samples for its key international partners in the coming months.

Zeta Energy Li-S Production

Our final piece of news comes from Zeta Energy, who recently announced that they’ve demonstrated the production of a lithium-sulfur battery using a dry process.

In most cases, battery electrodes are created using a wet process in which electrode materials are combined with a solvent which is eventually treated and dried. A major shortcoming of this method is that it is potentially hazardous to human health as well as the environment. Additionally, the drying process requires significant time, money, and energy. For lithium-sulfur batteries, which aim to be more sustainable the li-ion, this is far from ideal.

Instead, Zeta Energy has demonstrated that they can develop electrodes for lithium-sulfur batteries with a dry process that completely avoids the need for solvents and a drying process. The result is a lithium-sulfur battery that is more sustainable to manufacture - helping to further capitalize on the sustainable benefits of lithium-sulfur.

Lithium Sulfur for the Future?

There’s no doubt that alternatives to lithium-ion batteries are going to be necessary to unlock a performant and sustainable battery-powered future. To this end, lithium-sulfur batteries seem to be a strong contender. Now, with a variety of new advancements in the field, including investments from Stellantis and breakthroughs from Li-S Energy and Zeta Energy, it seems Li-S batteries is gaining some serious momentum.

About the Author(s)

You May Also Like