Driving Automotive Electrification: Interview with 3M’s Global Lab Director

A look at how 3M assists automotive customers in successfully transitioning to EVs while meeting EPA emission limits.

Assisting automotive customers in transitioning to electric vehicles (EVs) and meeting ambitious emission limits proposed by the EPA is paramount for mitigating climate change and improving air quality, leading to a cleaner and healthier environment. At the same time, assisting automotive customers in this transition fosters innovation and drives technological progress, leading to more efficient and affordable EVs in the long run.

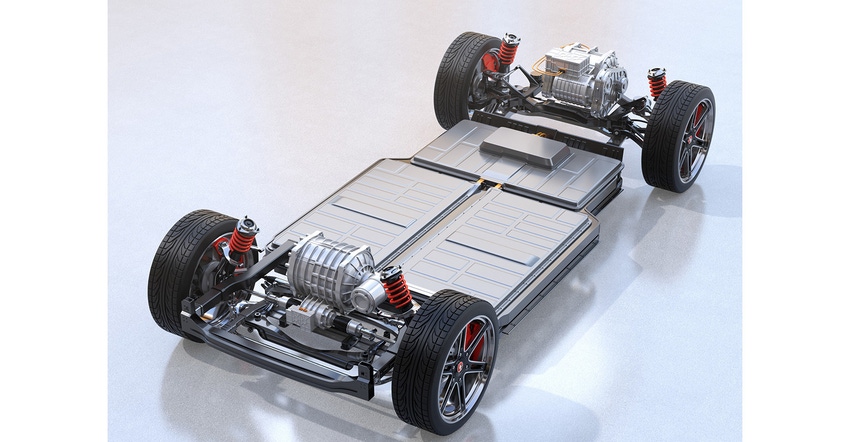

3M's automotive electrification business is dedicated to advancing automotive electrification technologies and providing innovative solutions for the electric vehicle (EV) industry. As an advanced materials science company, 3M leverages its expertise to develop and offer a wide range of products and technologies that support the transition to electric powertrains. Battery Technology spoke to 3M Global Lab Director for Automotive Electrification David Arney.

How does 3M plan to assist automotive customers in successfully transitioning to battery-electric vehicles and meeting the ambitious emission limits proposed by the EPA?

Arney: The proposed rules assume fewer than 60% of new light-duty and 40% of combined medium-duty van and pick-up sales will be electric by the model year 2032. The biggest challenge for our automotive customers to successfully transition to an electric vehicle (EV) future is profitably manufacturing affordable EVs. Electric powertrain design advancements to improve vehicle energy efficiency and reduce materials and assembly costs are a critical need for our automotive customers to build profitable, sustainable EV businesses.

3M is unique in the breadth of innovative product solutions and technologies we can bring to our automotive customers to solve some of their most difficult electric powertrain design challenges. 3M offers product solutions that help our customers achieve their electric powertrain design strategies for automated assembly, thermal/electrical management, component simplification, weight reduction, and improved energy efficiency.

What specific products or technologies does 3M offer that aligns with the requirements of the Biden administration's climate policy goals for the automotive industry?

Arney: 3M is an advanced materials science company at its core. 3M’s Automotive & Aerospace Division is significantly advancing automotive electrification technologies. 3M technology helps advance lighter, more durable, energy-efficient connected vehicles. As a trusted partner of vehicle manufacturers around the globe, 3M offers a wide array of solutions to help advance battery performance, such as thermal management, assembly, insulation, and more. Innovation in the EV space is essential as society—and the automotive industry —continues to transition to more climate-friendly, lower carbon footprint options.

Here are just three of hundreds of examples of innovative 3M product solutions to help our customers achieve their battery design targets to meet the requirements of the administration's climate policy goals for the automotive industry:

3M Sealant SZ1000 for EV Enclosure Sealing: It is a two-part, cure-in-place, flame retardant, foam, sealing solution designed for sealing enclosures such as battery packs. Moreover, it offers a resealable seal that can be opened and closed, allowing for battery servicing and ease of end-of-life recycling. The product can be dispensed automatically and meets specification IPX8 for water protection.

3M UVi Semi-Structural Insulation Tape 1924B-1: It is an electrical insulation of metal surfaces in the EV battery pack assembly, such as the battery cell can, a critical requirement. Most adhesive electrical insulation films use pressure-sensitive adhesives, which limit their bond strength to metal surfaces. New customer battery pack designs like cell-to-pack and cell-to-vehicle require stronger bonding adhesive electrical insulation films. This product offers semi-structural overlap shear performance combined with a fast and easy UV initiation process application for increased battery pack manufacturing productivity. Finally, managing battery cell temperature is a critical consideration for automotive OEMs as they strive to optimize EV efficiency and performance. Heating a battery in cold environments requires much power - much more than is necessary to keep it cool. Yet excessive temperatures can permanently impair the battery’s storage capacity and shorten its life.

3M Battery Enhancement Material 1807S: It helps our customers manage battery cell temperature. It can also prevent outside temperatures from heating the battery and help warm the battery in colder temperatures. This reduces power draw, meaning less battery power is required to keep the battery operating at its optimal temperature. Depending on battery design, environmental and interior vehicle temperatures, and consumer driving habits, the material can add range. The product is thin, much lighter than most current battery thermal management solutions, and is UL 94 V-0 flame resistant.

In what ways does 3M collaborate with automotive manufacturers to develop innovative solutions that support the transition to a low-carbon transportation sector?

Arney: 3M has an extensive global team of highly trained automotive application development engineers who can work directly “at the bench” with customers to bring 3M’s entire portfolio of automotive electrification product solutions to solve customer design challenges. Automotive electrification is a highly dynamic and rapidly evolving new industry. We often are presented with customer requests for product solutions beyond the capabilities of current 3M products or completely new design challenges. A strength of 3M is our application development engineers’ capability to reach out to science and engineering specialists within our vast, global R&D organization to help develop new solutions for our customers to consider.

Can you elaborate on the newer product solutions offered by 3M's Automotive Electrification business that support the transition to electric powertrains?

Arney: EVs are proving to have excellent reliability. However, to help manage the extreme conditions during the rare occurrence of a battery pack thermal runaway event, we have a broad portfolio of barrier products to help address the thermal, electrical, mechanical, and chemical challenges during such an event. Thermal runaway propagation challenges need solutions adaptable to different cell types and customer designs. For example, 3M above cell solutions can help address thermal isolation and stability concerns in cylindrical cell applications. 3M Thermal Barrier 5000 Series is a dispensable, lightweight silicone-based solution that helps protect neighboring cells from the energy from a failed cell by creating a fire retardant, electrically and thermally insulating barrier layer. 3M Flame Barrier Material FRB-NT is an inorganic-based, halogen-free material. It provides excellent ignitability resistance and perfect arc and track resistance. It is dimensionally stable (low moisture absorption and low shrinkage at high temperatures). 3M FRB-NT may also be used under the battery lid and between modules.

3M has combined our core technologies in ceramics, non-wovens, and advanced materials and developed a portfolio of between-cell materials that are compressible, high-temperature stable, and compatible with various cell types. 3M TRB600 and 3M TRB700 are engineered to perform within very limited space. The thin, compressible materials allow flexibility as battery cells expand and shrink during cell cycling. 3M also opened a new testing laboratory last year that our customers use to put their battery packs under extreme conditions.

Can you provide examples of successful partnerships between 3M and automotive customers that have resulted in measurable progress toward achieving the administration's climate policy goals?

Arney: While we cannot discuss specific OEMs, 3M does have Collaboration Agreements or Memorandums of Understanding with multiple major automotive customers. Partnerships like these are highly valuable for customers to gain full access to 3M Science and Innovation in our vast, global R&D organization. These partnerships enable 3M to fully collaborate with automotive customers at the electric powertrain platform advanced development stage for the development of new solutions to achieve their battery pack design requirements.

How does 3M ensure that its solutions for automotive electrification are environmentally friendly and commercially viable for customers looking to comply with the administration's climate policies?

Arney: More than ever, we need science to create a more positive future where everyone can thrive. To address these challenges, 3M is harnessing science-based innovations at scale to create more sustainable homes, businesses, and communities. As part of our new program, 3M Forward, we highlight our commitment to innovate to decarbonize industry and accelerate climate solutions. The global reach of our business, combined with our science-first approach to developing scalable solutions, positions us to tackle the world’s biggest and most pressing challenges.

About the Author(s)

You May Also Like