Flash Sintering for Ceramic Electrolytes

A new, lower-cost manufacturing technique for ceramic electrolytes might move us a step closer to solid-state lithium batteries.

March 17, 2021

Sintering is a fabrication or manufacturing process where material (in powder form) is formed and compacted into a solid mass using pressure and heat without melting. Typically used with metals, ceramics, or plastics, atoms diffuse across the boundaries of the particles and fuse the powder into one solid piece of the material. Sintering can be used to make complex objects and shapes and can be used to process high melting point metals such as tungsten, as it isn’t necessary to reach the material melting point temperature, reducing energy requirements. Sintering ceramics is of growing interest in the high-performance battery industry.

Batteries

Presently, lithium-ion batteries are used to power everything from cellphones and laptop computers, to electric vehicles (EV) to renewable electric power grids. The anode (negative electrode) of a lithium-ion battery is made from carbon graphite. Lithium ions are stored within the layers of the graphite during charging and released when the battery is discharged. There are only a limited number of lithium ions that can be stored in the graphite layers, however, limiting the amount of energy that a lithium-ion battery can store.

Lithium metal can be used as an anode, replacing the graphite and providing a vastly greater number of lithium ions that can participate in the electrochemical reaction, thus increasing the battery capacity by a factor of five or more. However, when the battery is charged, the lithium ions unevenly plate onto the surface of the lithium metal anode, creating spikey, needle-like crystals called dendrites. These dendrites can grow large enough to bridge across to the positive electrode (cathode) shorting out the battery and causing a fire.

One way to reduce or eliminate the formation of dendrites is to replace the liquid electrolyte between the anode and cathode with a solid made from polymer or ceramic. That’s where sintering comes in. The oxides used in ceramic electrolytes typically have very high melting points, so sintering without melting is under study as a way to fabricate ceramic electrolytes for solid-state lithium batteries while at the same time reducing the energy requirements in manufacturing.

Flash Sintering

With conventional sintering, producing a ceramic electrolyte can require several hours of processing at very high temperatures (1100°C). For a ceramic electrolyte, this can alter the chemical properties sufficiently to reduce the electrolyte’s effectiveness. Recently, a novel type of sintering, called flash sintering, has been under study by researchers at the University of Warwick, in the UK as a way to produce solid-state lithium electrolytes using less energy and creating fewer emissions.

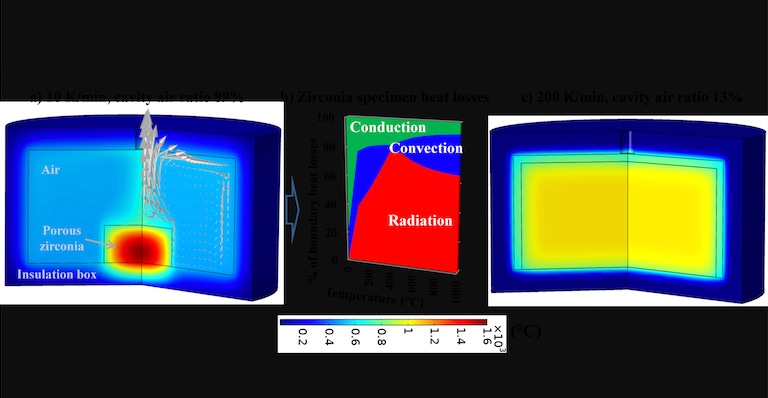

Flash sintering uses an electric current to heat a ceramic part internally rather than using only external furnace heating. This can lower ceramic processing temperatures to below 800°C and times to just a few seconds, greatly reducing energy requirements. It can also enable some ceramics to be co-processed with metals or other materials.

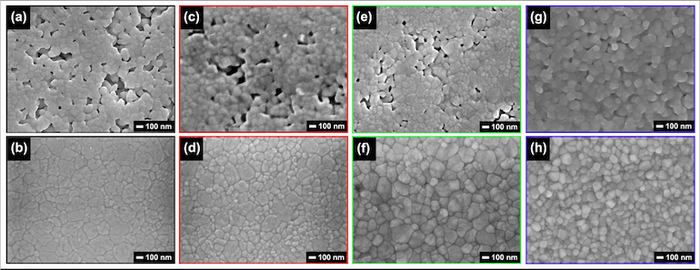

The problem is, flash sintering can result in low-quality ceramics caused by inhomogeneities in the ceramic microstructure that are caused by uneven temperature gradients in the material. Working in collaboration with academic and industrial partners, the University of Warwick study determined that the inhomogeneities could be controlled through:

Altering the method for applying electrodes

Improving thermal homogeneity through insulation

Tailoring the frequency of the AC current

Developing contactless methods for applying the electric current - which is currently limited to the consolidation of thermal barrier coatings.

Future Electrolytes

According to Dr. Claire Dancer, leader of the Ceramics Group within the Materials and Sustainability Directorate at WMG, University of Warwick, “Lowering ceramic processing temperatures by using techniques such as flash sintering is an essential step for manufacturing complex multi-material structures such as those needed for solid-state batteries, and for lowering overall energy use in the ceramic industry.” Dancer went on to comment, “However, the process must produce robust homogenous ceramic materials to be of widespread use. Our paper explains why flash sintering can result in inhomogeneous properties in ceramics and suggests a number of routes to mitigate these effects.”

Flash sintering has the potential to help in the quest for lower-cost ceramic electrolytes for solid-state lithium batteries, which promise higher energy density batteries with a longer range for EVs. The findings of the University of Warwick may help by providing a roadmap for thermal management in flash sintering, moving us a step closer to better battery systems.

Kevin Clemens is a Senior Editor with Battery Technology.

About the Author(s)

You May Also Like