Lamborghini Licenses MIT's Battery Tech for EVs

Lamborghini embraces sustainability, licensing MIT's cobalt-free battery tech for electric vehicles. Explore the eco-friendly future of EVs with this groundbreaking partnership.

Researchers are exploring alternatives to cobalt-containing batteries in pursuing environmentally friendly electric vehicle (EV) technologies. One significant avenue involves substituting cobalt with lithium iron phosphate (LFP) for cathodes. Simultaneously, groundbreaking research focuses on organic cathodes, eliminating cobalt. This article delves into the challenges and successes MIT researchers face as they optimize LFP batteries and pioneer organic cathodes, striving to create efficient and eco-friendly battery solutions. In a parallel endeavor, MIT has developed a novel lithium-ion battery material, now licensed by Lamborghini for their EVs. This breakthrough technology utilizes an organic cathode, eliminating the need for cobalt or nickel metals associated with high costs and environmental impact in traditional lithium-ion batteries.

Understanding the drawbacks of cobalt and the quest for alternatives

Most EVs rely on lithium-ion batteries with cobalt-containing cathodes, known for their stability and energy density. However, the drawbacks of cobalt include scarcity, price volatility, and ethical concerns related to mining practices, including issues like hazardous working conditions and environmental pollution. The new battery material, developed by MIT researchers, offers a more environmentally friendly and cost-effective solution.

While lithium-iron-phosphate (LFP) has emerged as a practical alternative, it falls short in energy density compared to cobalt and nickel batteries. Organic materials, another promising option, have faced challenges in matching the conductivity, storage capacity, and lifespan of cobalt-containing batteries.

Lamborghini's six-year collaboration and MIT's organic battery

The research, published in the journal ACS Central Science and titled “A Layered Organic Cathode for High-Energy, Fast-Charging, and Long-Lasting Li-Ion Batteries,” highlights the potential of organic cathodes and their impressive properties. The organic cathode created by MIT researchers demonstrated comparable electrical conductivity, storage capacity, and faster charging rates than traditional cobalt-containing batteries. Lamborghini's involvement in the project began around six years ago when they funded MIT's initiative to develop an organic battery for EVs. The researchers estimate that the material cost of assembling these organic batteries could be significantly lower, ranging from one-third to one-half the cost of cobalt batteries.

A layered organic cathode for high-energy, fast-charging, and long-lasting Li-Ion batteries: Courtesy of ACS Publications, licensed under CC-BY 4.0 [https://creativecommons.org/licenses/by/4.0/]

Professor Mircea Dincă, the W.M. Keck Professor of Energy at MIT and the senior author of the study, expressed optimism about the material's impact, stating, "It is already competitive with incumbent technologies, and it can save a lot of the cost and pain and environmental issues related to mining the metals that currently go into batteries."

Organic cathode performance

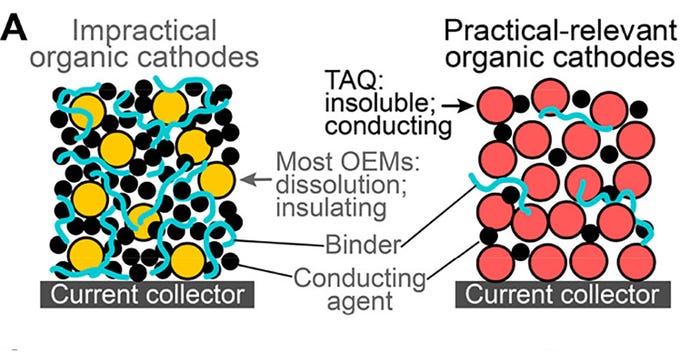

The new material comprises layers of TAQ (bis-tetraaminobenzoquinone), an organic molecule with unique properties. These layers resemble a graphite-like structure and exhibit stability due to the presence of chemical groups called quinones and amines. Dincă highlighted that the material's insolubility prevents it from dissolving into the battery electrolyte, a common issue with some organic battery materials. He stated that it leads to an extended lifetime of over 2,000 charge cycles with minimal degradation. Additionally, the newly developed batteries with a TAQ cathode exhibited faster charging and discharging capabilities, a promising aspect for EV charging efficiency.

Common organic cathodes with low active material content and TAQ-based cathodes with high and practical-relevant active material content. Courtesy of ACS Publications, licensed under CC-BY 4.0 [https://creativecommons.org/licenses/by/4.0/]

The researchers introduced filler materials such as cellulose and rubber, typically made of copper or aluminum, to enhance stability and adhesion to the battery's current collector. These fillers, making up a small fraction of the cathode composite, prevent cracking during lithium ion flow, thereby extending the battery cathode's lifespan.

Future endeavors: exploring sodium and magnesium alternatives

Looking ahead, Dincă's lab plans to continue developing alternative battery materials and explores the potential replacement of lithium with sodium or magnesium. These cheaper and more abundant alternatives could pave the way for even more sustainable and cost-effective EV technologies.

The partnership between Lamborghini and MIT signifies a pivotal moment in the electric vehicle (EV) industry, underscoring the significance of sustainable battery technologies. The introduction of cobalt-free organic battery technology represents a beacon of innovation, promising an environmentally conscious future for EVs. To facilitate widespread EV adoption, it becomes imperative to lower vehicle prices, ensuring accessibility and affordability for a broader consumer base. This collaborative effort not only transforms the industry but also aligns with the crucial goal of making eco-friendly EV solutions more within reach for the masses.

About the Author(s)

You May Also Like