MIT’s Concrete Supercapacitor Could Revolutionize Renewable-Energy Storage

Made of common cement, carbon black, and water, it could simplify and spread the use of renewables.

MIT researchers have uncovered an ingenious energy storage solution using commonplace materials—cement and carbon black—in a groundbreaking study. This innovative technology has the potential to reshape the renewable energy sector, including solar, wind, and tidal power, by bolstering energy grids against the fluctuations inherent in renewable energy supply, all without relying on conventional battery systems.

The researchers have harnessed the potential of cement and carbon black by combining them with water to create a supercapacitor—a viable alternative to traditional batteries—with the capacity to store electrical energy. To clarify the distinction between a supercapacitor and a battery, let's break it down: while batteries generate and store energy through chemical reactions, supercapacitors accumulate charges at the interface between electrolytes and electrodes. (There’s more to it than that: We’ve spelled out the differences between batteries and supercapacitors here.)

The researchers offer the example of integrating this supercapacitor technology within the concrete foundations of homes, enabling the storage of a full day's worth of energy without a substantial impact on costs or structural integrity. Furthermore, the researchers have conceived the concept of constructing concrete roadways that wirelessly recharge electric vehicles as they traverse the roadway's surface.

The fundamental workings of this novel technology are detailed in a paper published in the journal PNAS by MIT professors Franz-Josef Ulm, Admir Masic, Yang-Shao Horn, alongside collaborators from MIT and the Wyss Institute for Biologically Inspired Engineering. At its core, a capacitor comprises two conductive plates separated by an electrolyte and membrane. Upon applying a voltage, charged ions amass on the plates, engendering an electric field. Supercapacitors, a specialized type of capacitor, excel in storing substantially larger charges.

How it works

The novelty of this supercapacitor innovation emanates from the development of a cement-based material boasting an exceptionally expansive internal surface area due to a network of conductive matter interlaced within its structure. By integrating carbon black—a remarkably conductive substance—into a concrete blend alongside cement and water, the researchers engineer a labyrinthine arrangement of interconnected conductive structures within the hardened cement.

These structures emulate branching networks of varying sizes, resulting in a vast surface area within a comparatively modest volume. Subsequently, the material is infused with an electrolyte, such as potassium chloride, prompting the formation of charged particles on the carbon structures. When two electrodes, forged from this material, are separated by a thin gap or insulating layer, a potent supercapacitor materializes.

This supercapacitor breakthrough holds significant promise for stationary energy storage, pivotal in accommodating the sporadic nature of renewable energy sources. In stark contrast to conventional batteries relying on materials like lithium, which are both limited and expensive, the proposed supercapacitor technology leverages cement—a plentiful and cost-effective resource.

Calculations by the research cohort indicate that a 45-cubic-meter block of nanocarbon-black-doped concrete could effectively stockpile roughly 10 kilowatt-hours of energy, equating to the average daily electricity consumption of a household. This could empower residences with foundations constructed from this material to hoard energy generated by solar panels or wind turbines, utilizing it when needed. Notably, supercapacitors boast swift charge and discharge rates, rendering them immensely efficient for energy storage.

As this technology advances, the researchers intend to engineer larger iterations of the supercapacitors for diverse applications. They acknowledge an inherent trade-off between storage capacity and structural robustness, with increased carbon black content bolstering energy storage while marginally weakening the concrete. Hence, the optimal composition for applications necessitating both energy storage and structural integrity, such as foundations or structural components, hovers around 10 percent carbon black.

Scaleable—and roadworthy?

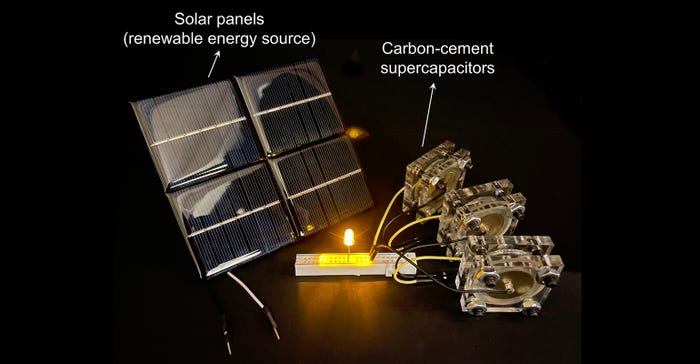

An alluring prospect involves fabricating concrete roadways embedded with supercapacitors to harness solar energy and wirelessly charge electric vehicles traversing the road. Preliminary applications of this technology could extend to remote areas lacking power grid access, where solar panels connected to cement supercapacitors could furnish electricity.

The scalability of energy-storage capacity directly corresponds to the electrode volume. This adaptability accommodates a gamut of applications, from powering minuscule devices to satisfying the energy demands of entire households. The research consortium comprises experts spanning diverse disciplines, encompassing civil and environmental engineering, mechanical engineering, and materials science.

This groundbreaking innovation has garnered support from the MIT Concrete Sustainability Hub and the Concrete Advancement Foundation. In essence, the convergence of ubiquitous materials—cement and carbon black—has paved the way for a transformative energy storage solution, portending far-reaching implications for the realm of renewable energy.

About the Author(s)

You May Also Like