Micrometers-Thin Battery Is Charged by Saline Solution—or Tears

NTU Singapore’s flexible battery for smart contact lenses is as thin as a human cornea and stores electricity when immersed in saline solution—or even human tears.

August 28, 2023

Scientists from Nanyang Technological University, Singapore (NTU Singapore) have developed a flexible battery as thin as a human cornea, which stores electricity when it is immersed in saline solution—or tears—and which could one day power smart contact lenses.

Smart contact lenses are high-tech contact lenses capable of displaying visible information on our corneas and can be used to access augmented reality. Current uses include helping to correct vision, monitoring wearers' health, and flagging and treating diseases for people with chronic health conditions such as diabetes and glaucoma. In the future, smart contact lenses could be developed to record and transmit everything a wearer sees and hears to cloud-based data storage.

However, to reach this future potential a safe and suitable battery needs to be developed to power them. Existing rechargeable batteries rely on wires or induction coils that contain metal and are unsuitable for use in the human eye, as they are uncomfortable and present risks to the user.

The NTU-developed battery is made of biocompatible materials and does not contain wires or toxic heavy metals, such as those in lithium-ion batteries or wireless charging systems. It has a glucose-based coating that reacts with the sodium and chloride ions in the saline solution surrounding it, while the water the battery contains serves as the ‘wire’ or ‘circuitry’ for electricity to be generated.

The battery could also be powered by human tears as they contain sodium and potassium ions, at a lower concentration. Testing the current battery with a simulated tear solution, the researchers showed that the battery’s life would be extended an additional hour for every twelve-hour wearing cycle it is used. The battery can also be charged conventionally by an external power supply.

Associate Professor Lee Seok Woo, from NTU’s School of Electrical and Electronic Engineering (EEE), who led the study, said: “This research began with a simple question: Could contact lens batteries be recharged with our tears? There were similar examples of self-charging batteries, such as those for wearable technology that are powered by human perspiration.

“However, previous techniques for lens batteries were not perfect as one side of the battery electrode was charged and the other was not. Our approach can charge both electrodes of a battery through a unique combination of enzymatic reaction and self-reduction reaction. Besides the charging mechanism, it relies on just glucose and water to generate electricity, both of which are safe to humans and would be less harmful to the environment when disposed of, compared to conventional batteries.”

Co-first author Dr Yun Jeonghun, a research fellow from NTU’s EEE stated, “The most common battery charging system for smart contact lenses requires metal electrodes in the lens, which are harmful if they are exposed to the naked human eye. Meanwhile, another mode of powering lenses, induction charging, requires a coil to be in the lens to transmit power, much like a wireless charging pad for a smartphone. Our tear-based battery eliminates the two potential concerns that these two methods pose, while also freeing up space for further innovation in the development smart contact lenses.”

Highlighting the significance of the work done by the research team, NTU School of Mechanical & Aerospace Engineering Associate Professor Murukeshan Vadakke Matham, who specializes in biomedical and nanoscale optics and was not involved in the study, stated, “As this battery is based on glucose oxidase, which occurs naturally in humans and powered by chloride and sodium ions, such as those in our tears, they should be compatible and suitable for human usage. Besides that, the smart contact lenses industry has been looking for a thin, biocompatible battery that does not contain heavy metals, and this invention could help further their development to meet some unmet needs of the industry.”

A battery to cry over

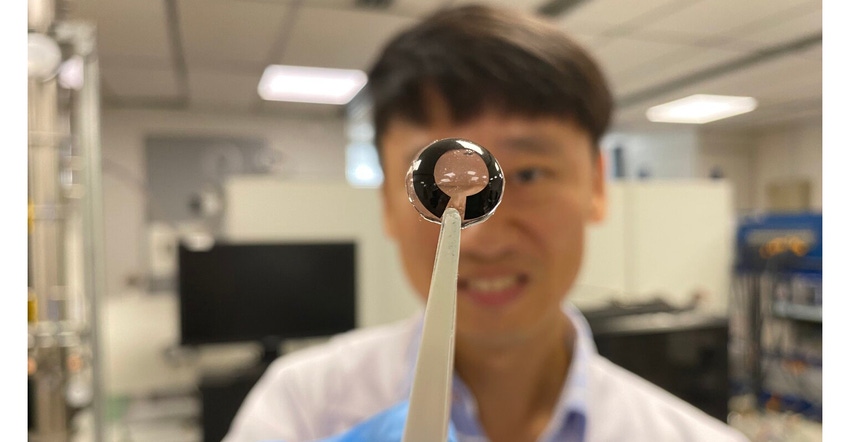

The team demonstrated their invention using a simulated human eye. The battery, which is about 0.5 µm-thin generates electrical power by reacting with the basal tears—the constant tears that create a thin film over our eyeballs—for the devices embedded within the lenses to function.

The flexible and flat battery discharges electricity through a process called reduction when its glucose oxidase coating reacts with the sodium and chloride ions in the tears, generating power and current within the contact lenses.

The team demonstrated that the battery could produce a current of 45 microamperes and a maximum power of 201 microwatts, which would be sufficient to power a smart contact lens.

Laboratory tests showed that the battery could be charged and discharged up to 200 times. Typical lithium-ion batteries have a lifespan of 300 to 500 charging cycles.

The team recommends that the battery be placed for at least eight hours in a suitable solution that contains a high quantity of glucose, sodium, and potassium ions, to be charged while the user is asleep.

Co-first author Li Zongkang, a PhD student from NTU’s EEE stated: “Although wireless power transmission and supercapacitors supply high power, their integration presents a significant challenge due to the limited amount of space in the lens. By combining the battery and biofuel cell into a single component, the battery can charge itself without the need for additional space for wired or wireless components. Furthermore, the electrodes placed at the outer side of the contact lens ensures that the vision of the eye cannot be obstructed.”

The NTU team will be conducting further research to improve the amount of electrical current their battery can discharge. They will also be working with several contact lens companies to implement their technology.

The findings were published in the scientific journal Nano Energy in June.

About the Author(s)

You May Also Like