Electric Vehicle Battery Cooling Methods Are Evolving

Battery packs generate heat while they charge or discharge, therefore they need to be cooled to protect their performance and their life span. Let’s explore the most common current and most promising future EV battery cooling methods.

Thermal management is crucial for performance, reliability, and safety of batteries. There are different methods available to maintain the ideal temperature in a battery pack for an electric vehicle (EV). Here are two of the most common EV cooling methods:

1.Air cooling: This method employs air to cool the battery. When air runs over the surface of a battery pack it carries away the heat emitted by it. Cooling is possible by forced convection (active cooling) or by natural convection (passive cooling). Passive air cooling uses air from the outdoors or from the cabin of the EV while active air cooling uses an external device such as a fan to cool a battery pack. This method of cooling can be challenging to implement in EVs because bracing and mounts can get in the way of airflow, making the airflow’s distribution difficult.

But because this method has very low maintenance costs some automakers prefer to use it over other cooling methods. The Nissan LEAF was one of the first EVs to use an air cooling method. Over the years, Nissan has made changes to the chemistry of the Nissan LEAF battery pack, but it still uses air cooling.

The design for an air-cooled system can be simple and cost-effective, but the air cooling method still tends to not be as popular or as sufficient as liquid cooling for EVs.

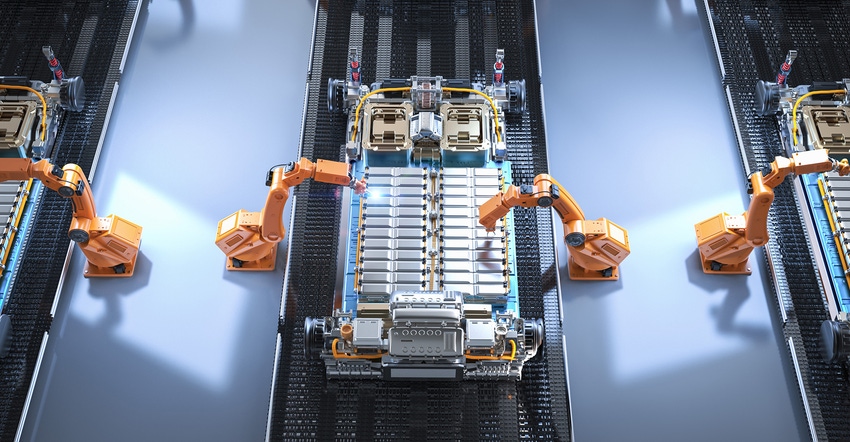

2.Liquid cooling: This method is one of the most popular due to its good performance even though it contains more components, and therefore is more expensive, than an air-cooled system. A liquid coolant such as water, a refrigerant, or ethylene glycol—a type of liquid coolant also found in antifreeze—is used for the purpose of cooling the battery. There are other components involve in the system such as tubes, cold plates, and heat exchangers.

There are two types of liquid cooling methods: direct cooling and indirect cooling.

Indirect cooling: This is a cooling method that successfully prevents electrical conduction with cells while maintaining high thermal diffusion. Indirect cooling is similar to an internal combustion engine (ICE) cooling system because both circulate liquid coolant through cooling channels attached to the surface of the battery cell.

Direct cooling: It is also called immersion cooling, where the cells of a battery pack are in direct contact with a liquid coolant that covers the entire surface and can cool a battery pack uniformly. No cooling jacket is needed, and the ideal liquid coolant must be a dielectric fluid (very poor conductor of electric current) with high thermal conductivity and thermal capacity. Direct cooling systems are still in the research and development stage and are not commercially available yet.

Lubrizol—a provider of specialty chemicals for the transportation, industrial and consumer markets—states “Based on initial testing, it becomes increasingly clear that immersion cooling is a superior battery thermal management technology that will become standard to cool high-performance EV batteries in the future. As the technology emerges into real-world applications, it becomes worthwhile to partner with companies that understand how to formulate effective, durable, and safe dielectric fluids for each specific EV battery system.”

Liquid cooling has been successfully used in datacenters for years and more recently in some EV models such as the Tesla Model X, Model S, and Model 3, to name a few.

Battery cooling methods will continue to be an important focus as performance of batteries improve even further. According to Allied Market Research, the global EV battery thermal management system industry was accounted for $2.3 billion in 2021, and is expected to reach $8.4 billion by 2031, growing at a CAGR of 14.6% from 2022 to 2031.

About the Author(s)

You May Also Like