Vehicle Electrification Alone Will Not Save the Planet

To stay on the 1.5-degree pathway for 2050 established by the Intergovernmental Panel on Climate Change, the global share of BEV sales would have to be close to 100% by 2032. That’s unrealistic.

February 10, 2023

A 100% switch to battery electric vehicles (BEVs) won’t be enough to save the planet, according to a study commissioned, perhaps surprisingly, by two leading BEV proponents — Polestar and Rivian. They contend that only a fundamental repositioning of the automotive industry will prevent it from overshooting the Intergovernmental Panel on Climate Change (IPCC) target of 1.5°C of global warming by 2050. This view is detailed in the “New Pathway Report” prepared by consultant Kearney on behalf of the two automakers.

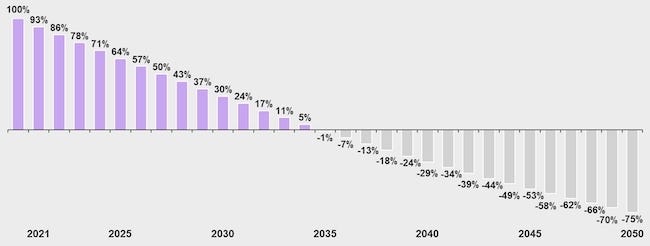

Passenger vehicles currently account for 15% of all greenhouse gas (GHG) emissions globally. The IPCC has stated that all GHG emissions need to be reduced by 43% by 2030, and the report makes clear that the automotive industry is well off track. Alarmingly, the sector will have spent its entire CO2 budget by 2035 without urgent action.

|

If it continue to do business as usual, the auto industry will wildly overshoot the Intergovernmental Panel on Climate Change (IPCC) target of 1.5°C of global warming by 2050. |

To stay on the 1.5-degree pathway for 2050, BEV share of sales must grow from 6% to close to 100% globally by 2032. Given that a transition of this magnitude is impossible from an infrastructure and socio-economic perspective, the “New Pathway Report” emphasizes the fast-track implementation of two more “levers” to accelerate the shift to sustainability:

Increasing renewable energy in power grids;

reducing greenhouse-gas emissions in the manufacturing supply chain.

Pulling just one or two levers in isolation will be insufficient and only reduce the overshoot, according to the report. Collective action from automakers is needed on all three levers, in parallel, at a global level.

First, the industry must accelerate the transition to electric vehicles by investing in manufacturing capabilities, as well as implementing a firm end date for fossil fuel car sales globally.

Second, renewable energy supply must be built out to global grids that enable EVs to reach their full potential through green charging.

Third, and this is paramount, the manufacturing supply chains for these vehicles must be decarbonized by switching to low-carbon materials and investing in renewable energy solutions.

“Car companies may be on different paths when it comes to brand, design, and business strategies, and some won’t even admit that the road to the future is electric,” commented Fredrika Klarén, Polestar's head of sustainability. “I believe it is and that the climate crisis is a shared responsibility — we must look beyond tailpipe emissions. This report makes clear the importance of acting now and together. There’s a clear cost to inaction, but there’s also a financial opportunity for innovators who find new answers to the challenges we face.”

|

"[Some] car companies won’t even admit that the road to the future is electric,” commented Fredrika Klarén, Polestar head of sustainability. |

Anisa Costa, Rivian’s chief sustainability officer, added: “The report’s findings are sobering. Our hope is that this report lays the groundwork for the automotive industry to collaborate in driving progress at the pace and scale we need — and ideally inspiring other industries to do the same. Together, I’m confident we can win the race against time.”

Increased adoption of low-carbon materials has implications for plastics take-up in vehicles, particularly for grades based on recycled content and chemically recycled and biomass-based feedstocks, according to analysts. Suppliers in Europe are already touting sustainable polypropylene (PP) as an option for durable applications such as automotive, while recent announcements by Braskem and Citroniq Chemicals hold promise for local supply of bio-based PP within a timeframe of several years.

About the Author(s)

You May Also Like