Chip-on-Cell: Advancing EV Battery Sustainability

Dukosi's Chip-on-Cell tech enhances EV battery safety, efficiency, and traceability through continuous monitoring, transforming the battery value chain.

October 10, 2023

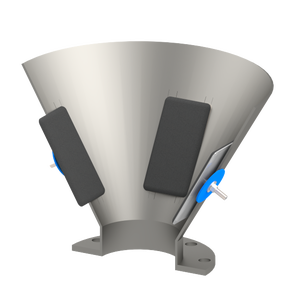

Dukosi Ltd—a company that provides a unique battery monitoring system based on near-field wireless communication and intelligent Chip-on-Cell technology—announced their unique chip-on-cell battery monitoring platform is enabling a circular economy by helping to reduce, reuse, and recycle throughout the battery value chain.

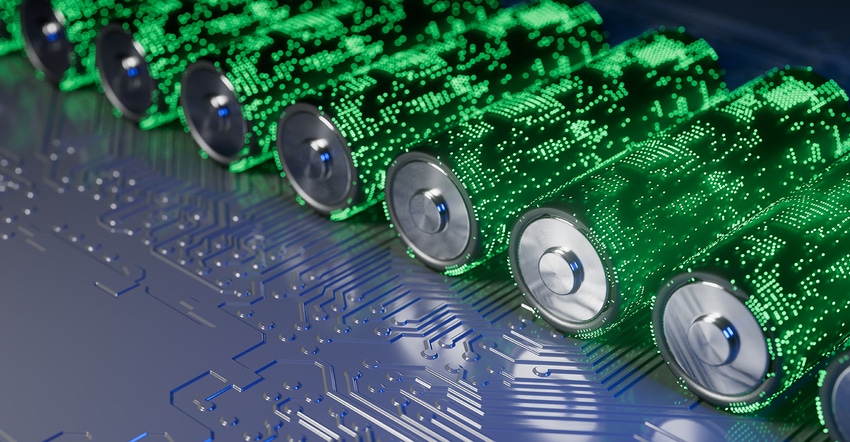

Dukosi’s intelligent chip-on-cell solution transforms the way batteries are designed and monitored. The solution continuously measures cell parameters, such as temperature and voltage, with a chip on every cell. In addition, on-cell storage provides lifetime traceability with a unique ID, materials provenance, and 24/7 data and event logging commencing from the first instant the Cell Monitor IC is installed. This advanced cell monitoring technology provides enhanced safety and performance throughout the battery's life, from first-life applications such as electric vehicles (EV) to second/third-life use in energy storage systems to end-of-life and recycling.

“Consumer adoption of electric vehicles continues to grow as the world moves toward greater electrification and transition to net-zero emissions,” stated Nat Edington, CEO of Dukosi. “Considering the potential of over 100M EV batteries coming to end-of-life in the next decade, designing batteries for sustainability is an economic, social, and environmental imperative. We are already seeing adoption of regulatory requirements for traceability at the battery level, but full traceability can only be achieved at the cell level, the smallest unit of the battery system, to achieve a truly circular economy.”

Dukosi’s patented chip-on-cell technology with lifetime traceability has many advantages over existing battery monitoring solutions, providing higher levels of safety, performance, and efficiency throughout the battery value chain. For example, during cell manufacturing, Dukosi’s Cell Monitor IC captures provenance data and starts 24/7 monitoring and lifetime data logging of the cell’s voltage and temperature from day one, providing a more efficient manufacturing process and shorter test cycles.

For pack builders, the 24/7 cell monitoring and lifetime event logging provides safer cell storage and transport, pack manufacturing and warehouse handling, and improved aging predictions. Moreover, the solution allows a flexible pack design and improved maintenance by replacing the cells that do not meet requirements. For OEMs and battery owners, more granular and accurate data stored on cells can improve battery safety and performance, warranty and liability protection, and better residual value assessment. As provenance and lifetime data, including event logging stays with the cell, battery utilization and safety can be improved in second-life and third-life use, e.g., in energy storage systems, to end-of-life and recycling.

Dukosi will move to volume production of its unique cell monitoring solution based on chip-on-cell technology and contactless communication by the end of the year. This innovative technology enables flexible battery design, optimized battery performance, high safety standards, and lifetime cell traceability—in automotive, stationary energy storage, and industrial applications.

About the Author(s)

You May Also Like