DOE Boosts 17 Battery Recycling Projects with $62 Million

Why these projects? Why this approach? The US Department of Energy’s vehicle technology director explains.

April 15, 2024

On March 28, the US Department of Energy (DOE) announced $62 million in funding from the Bipartisan Infrastructure Law (BIL) to fund 17 battery recycling projects designed to both improve the economics of battery recycling and increase consumer participation nationwide.

“Investments in sustainable reduced-cost recycling of consumer batteries are critical to securing the domestic materials supply chain,” the DOE announcement said, citing a projected tenfold increase in demand for lithium-ion batteries for electric vehicles (EV), consumer electronics, and stationary energy storage by 2030.

“Capturing the full battery supply chain—from sourcing critical materials to manufacturing to recycling—puts the US in the driver’s seat as we build our clean energy economy,” stated US Secretary of Energy Jennifer Granholm in the announcement. “With the support of the Investing in America agenda, we are creating a sustainable, circular supply chain that lowers costs for consumers and boosts our global manufacturing competitive edge.”

Why not national?

Spanning the country, these 17 projects (enumerated below) and their DOE backing form an impressive array of battery recycling efforts and increased awareness. DOE’s Vehicle Technology Office (VTO) and Office of Manufacturing and Energy Supply Chains (MESC) are overseeing the funding program.

Why was the effort pointed at state and local and not a national “Only You Can Prevent Forest Fires�” type of program?

“There is a big established ecosystem for recycling traditional lead-acid car batteries, but collecting lithium-ion batteries from consumer electronics remains a nascent effort,” Austin Brown, director of DOE’s Vehicle Technologies Office, told Battery Technology.

“Focusing on state and local projects addresses two specific program goals: increase the overall amount of spent battery feedstock and raise overall process efficiencies,” he said. “By working throughout the battery supply chain from beginning to end, we are looking at these projects to establish best practices and scaleability efforts the entire industry can benefit from.”

Austin Brown, Ph.D., director of DOE’s Vehicle Technologies Office. Credit: DOE

Brown added that the DOE funding project helps the US focus on emerging battery chemistries and materials (and their recyclability) in a strategic fashion. “For example, we’re looking at much less cobalt in the battery supply chain today versus five years ago. The result is better batteries and a stronger supply chain with less reliance on harder-to-source materials.

“On balance, this program represents a really strong offense,” he concludes. “There’s never been a better time to be in batteries.

More on the 17 awarded projects

The 17 projects in what the DOE is calling its 'Consumer Electronics Battery Recycling, Reprocessing, and Battery Collection' funding opportunity are organized under three broad perspectives:

Implementing projects to assist state and local governments to initiate and establish battery collection, sorting, recycling, and reprocessing efforts. Project awardees include:

$2.98 million to Idaho National Laboratory for its project “Comparing strategies to collect battery-containing devices in states with and without electronics recycling laws.”

$4.9 million to Harris County, Texas, together with the Houston Zoo, CORE Design Studio, University of Houston, and Elevate Communications for “ZEEBRA: Zoos Educating on Electronics and Battery Recycling Awareness.”

$1.8 million to Macalaster (MN) College and project partners RECharge Labs, Field Guide Upstream Exhibits, Repowered, and STEM Educational Insights for “The CollectED Project.”[end bullets]

Improving the Economics of Recycling Consumer Electronics Batteries. Project awardees include:

$4.0 million to UHV Technologies Inc., together with project partners Penn State and Purdue Universities for “Low-Cost Modular System for Collecting and Recycling Consumer Batteries from MSW Using Artificial Intelligence.”

$7.0 million to Li Industries Inc. and project partners Argonne National Laboratory and Call2Recycle Stewardship Inc., for “Integrated Automated Sorting and Battery Neutralization to Reduce End-of-Life Logistics Costs for Lithium-Ion Battery Recycling.”

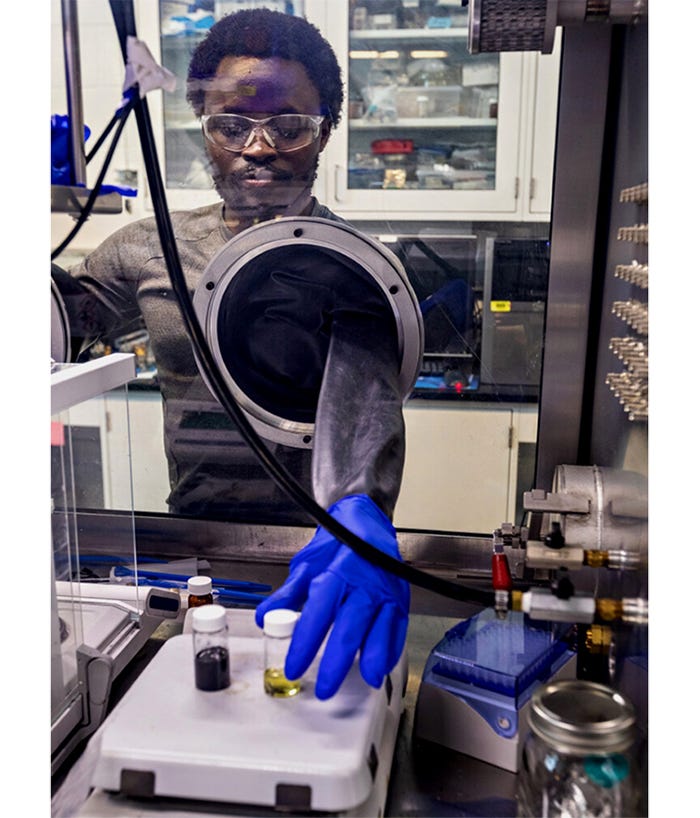

Chemistry researcher Cyrus Kirwa performing redox relithiation as part of NREL battery recycling research. Credit: Werner Slocum / NREL

$5.5 million to Reaction Engineering International together with project partners Bringham Young University, Massachusetts Institute of Technology, and San Rafael (Calif.) Energy Research Center for “A Clean and Affordable Low-Temperature Thermal Method to Preprocess End-of-Life Lithium-Ion Batteries from Consumer Devices.”

$5.2 million to MOLG Inc. together with Virginia Commonwealth University for “Improving Consumer Electronics Battery Recycling.”

State and Local Programs for Consumer Electronics Battery Collection, Recycling, and Reprocessing. Project awardees include:

$2.15 million to the New York City Department of Sanitation together with Veolia ES Technical Solutions, LLC for establishing a Mobile Battery Drop-off program.

$2 million to the Illinois Environmental Protection Agency together with 11 city and county agencies under the title “Recharging Local Battery Collection.”[end bullets]

On March 28, 2024, DOE announced the selection of 11 projects for areas of interest 1 and 2 for $54.5 million in funding, to be administered by the DOE’s Vehicle Technologies Office (VTO), and selection of 6 projects for areas of interest 3 for $7 million in funding, to be administered by the Office of Manufacturing and Energy Supply Chains (MESC).

About the Author(s)

You May Also Like