Toshiba's New Cathode: Advancing Sustainable Energy Solutions

Explore the evolution of lithium-ion batteries with cathode innovations. Toshiba's cobalt-free 5V-class high-potential cathode paves the way for sustainable, high-performance energy storage solutions.

Cathode materials are crucial in various electrochemical devices, from batteries to fuel cells. These materials are integral to the overall performance and efficiency of such systems. In the context of rechargeable batteries, cathode materials are responsible for storing and releasing electrical energy during the charge and discharge cycles. Common cathode materials include metal oxides, such as lithium cobalt oxide (LiCoO2), lithium iron phosphate (LiFePO4), and nickel manganese cobalt oxide (NMC).

The selection of cathode material significantly impacts a battery's energy density, cycle life, and safety. Ongoing research and development efforts are dedicated to identifying and creating new cathode materials with improved properties, addressing the escalating requirements for high-performance and sustainable energy storage solutions. Researchers and companies are actively pushing the boundaries of cathode materials to enhance energy storage systems' efficiency, sustainability, and overall performance.

Among the notable breakthroughs, Toshiba Corporation's recent announcement stands out as a prime example of cutting-edge research, showcasing the potential of emerging technologies in revolutionizing cathode innovations.

Toshiba’s new cobalt-free high-potential cathode material

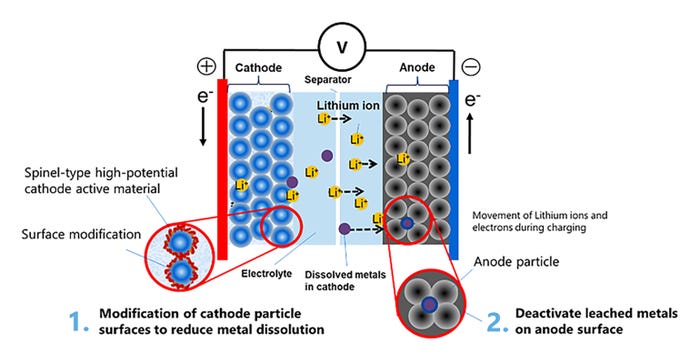

Toshiba successfully prototyped a pouch lithium-ion battery, integrating its innovative cobalt-free 5V-class high-potential cathode with a niobium-titanium oxide (NTO) anode. Toshiba's innovative cathode represents a substantial advancement by markedly reducing gas generation when coupled with a conventional high-conductivity electrolyte.

The company also developed a technology that deactivates the transferred ions on the anode surface. In combination, these technologies successfully suppress gas generation that could diminish battery performance, even with a conventional high-conductivity electrolyte.

The NTO anode—known for its stability and high conductivity—complements the cathode's capabilities, contributing to the battery's exceptional performance. This match-up enables the prototype to achieve a high voltage exceeding 3V, rapid charging to 80% capacity in just 5 minutes, robust power performance, and remarkable lifetime characteristics, even in demanding conditions such as a temperature of 60°C.

Toshiba's newly developed technology. Courtesy of Toshiba

Toshiba's prototype demonstrates the viability of its groundbreaking cathode technology and emphasizes the importance of a holistic approach in optimizing both cathode and anode materials. This successful integration holds promising implications for diverse applications, ranging from power tools and industrial equipment to the burgeoning electric vehicle market, shaping the trajectory of future energy storage solutions.

This new cathode technology boosts the evolution of lithium-ion batteries and addresses critical concerns associated with traditional stabilizing elements like cobalt and nickel. Cobalt poses challenges to cost stability and supply-chain reliability, while the heightened demand for nickel in recent years has led to market price fluctuations. Toshiba's commitment to a cobalt-free cathode with reduced nickel content contributes to sustainability. It underscores the necessity of diversifying and innovating cathode materials for a more secure and cost-effective energy storage future.

About the Author(s)

You May Also Like