6K Energy Secures $50M DOE Award for PlusCAM Battery Material Plant in Jackson, TN

The sustainable battery material production plant is expected to deliver cathode active material more cheaply than China.

6K Energy, a front-runner in sustainable lithium-ion battery materials, has clinched a $50M grant from the US Department of Energy (DOE) for its PlusCAM battery material production facility in Jackson, TN. The investment, part of the more than $200M construction cost, reinforces 6K Energy's commitment to revolutionizing cathode active material (CAM) production with its UniMelt microwave plasma technology.

As 6K Energy President Sam Trinch explained to Battery Technology last year, UniMelt “leapfrogs legacy battery material processing technology with proven 6,000-degree Kelvin microwave plasma technology.” The process can produce multiple chemistries at ultra-high speeds and substantially lower cost, with significantly less environmental impact than traditional processes, Trinch said: “UniMelt can produce battery material using 90% less water, generating zero solid and liquid waste and significantly less energy and CO2 emissions.”

The PlusCAM facility aims to set a new standard for supplying CAM to major automotive OEMs and suppliers, marking a crucial step in reducing reliance on China and enhancing US battery supply chain resilience. With construction underway and full-scale production set for late 2024, the facility will boast industry-leading ESG metrics, aligning with the Bipartisan Infrastructure Law's goals of fostering domestic battery supply chain growth.

China-independent CAM

“The national concern is focused on onshoring battery cells, but it's severely misguided. The most critical item needed to break our reliance on China is CAM. No other production technology, other than UniMelt plasma, is capable of producing CAM with acceptable ESG levels and at costs lower than Asia,” Trinch stated this week. “We are negotiating offtake agreements to commit our PlusCAM capacity, and the $50M grant helps us reach full-scale production beginning in late 2024 to meet our customer's CAM supply requirements.”

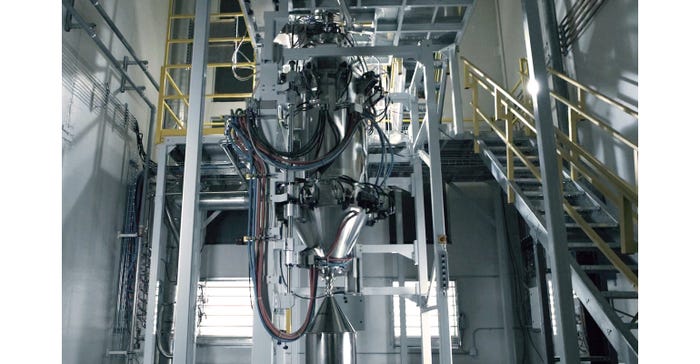

UniMelt microwave plasma technology. (Credit: 6K Energy)

As a first-of-its-kind sustainable production facility, PlusCAM emphasizes 6K Energy's commitment to zero hazardous waste, 90% less water use, lower energy consumption, and fewer carbon emissions than traditional production methods. UniMelt technology, already proven at 6K Energy's sister company, 6K Additive, is ISO 9001 certified, operating at full-scale production in Burgettstown, PA, further bolstering US supply chain independence. The PlusCAM plant, spanning 160,000 sq/ft, will produce multiple cathode active materials, including NMC and LFP chemistries, and is set to employ approximately 230 individuals when at full-scale capacity.

With a commitment to diversity, 6K Energy aims to hire 40% of its workforce from disadvantaged, veteran, disabled, or diverse communities, aligning with the Bipartisan Infrastructure Law and the Justice 40 Initiative. The $50M grant will facilitate construction and workforce development, ensuring a safe work environment, high-value training programs, and a positive working experience in the Jackson, TN facility.

About the Author(s)

You May Also Like