GM Finds New Nickel Supply for Lithium-Ion Battery Cathodes

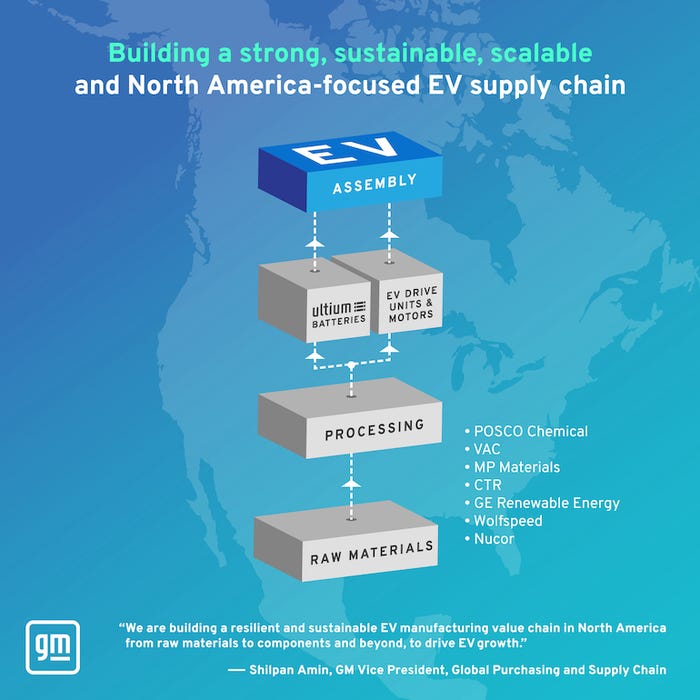

GM’s North America EV supply chain will add a new joint venture with POSCO Chemical in Canada to process nickel cathode active materials.

March 30, 2022

General Motors Co. (GM) and POSCO Chemical of Korea have announced that they are working with the governments of Canada and Quebec to build a new facility in Bécancour, Quebec. The new $400 million facility will produce cathode active material (CAM) for GM’s Ultium lithium-ion batteries.

According to information provided in a POSCO news release, Bécancour is an optimal location for the cathode active material business in North America in terms of raw material, investment, manufacturing technology, and eco-friendliness. Quebec Province has advantages in raw material supply chain and logistics facilities adjacent to mines, and abundant hydro and renewable energy. Canada has significant reserves of nickel, including large deposits in Quebec.

The new facility will supply the Ultium Cells LLC facilities GM and LG Energy Solution are building in Lordstown, Ohio and Spring Hill, Tennessee. Two more U.S.-based Ultium cell plants are planned by mid-decade as GM drives mass adoption of EVs with high-volume Ultium-powered EVs.

GM has developed its Ultium lithium-ion battery to power electric vehicles such as the Chevrolet Silverado EV, GMC HUMMER EV, and Cadillac LYRIQ. POSCO Chemical is a global advanced materials company dedicated to batteries for future mobility. It is producing high-capacity Ni-rich cathode materials and low-expansion anode materials for EV batteries. In addition, POSCO is working on technologies such as NCMA cathode, silicon anode, and materials for solid-state batteries.

Construction on the new facility, which the joint venture will operate, will begin immediately and will create approximately 200 jobs. The site’s construction will allow for future expansion opportunities as GM continues to pursue many potential future EV supply chain projects.

“GM and our supplier partners are creating a new, more secure and more sustainable ecosystem for EVs, built on a foundation of North American resources, technology, and manufacturing expertise,” said Doug Parks, GM executive vice president, Global Product Development, Purchasing and Supply Chain in a GM news release. “Canada is playing an important role in our all-electric future, and we are grateful for the strong support we have received from local, provincial, and national officials to grow a North American-focused EV value chain.”

The Quebec site will process CAM, a key battery material consisting of components like processed nickel, lithium, and other materials representing about 40% of the cost of a battery cell.

“It is so exciting to see GM Canada and Quebec playing a key role in building the emerging ‘mines to mobility’ EV battery ecosystem in North America,” said Scott Bell, president, and managing director, GM Canada. “With this new processing facility in Bécancour, GM will help lead the EV battery supply chain while also launching Canada’s first full EV manufacturing plant in Ingersoll, Ontario, later this year.”

By the end of 2025, GM plans to have the capacity to build 1 million electric vehicles in North America, and the company targets the majority of components by value to be sustainably sourced, processed, or manufactured in North America.

Kevin Clemens is a Senior Editor with Battery Technology.

About the Author(s)

You May Also Like