Cobalt-Free Cathodes Eyed for Next-Generation Li Batteries

DoE researchers are working with a new class of materials that are easier to source and offer performance benefits.

April 18, 2021

Lithium-ion batteries typically use cobalt-based cathodes, which are expensive because of the complexity of sourcing the metal material.

Now researchers at the Department of Energy (DoE) have found a cobalt-free alternative that can enhance batteries in other ways, including improvements in charging speed, energy density, and longevity, they said.

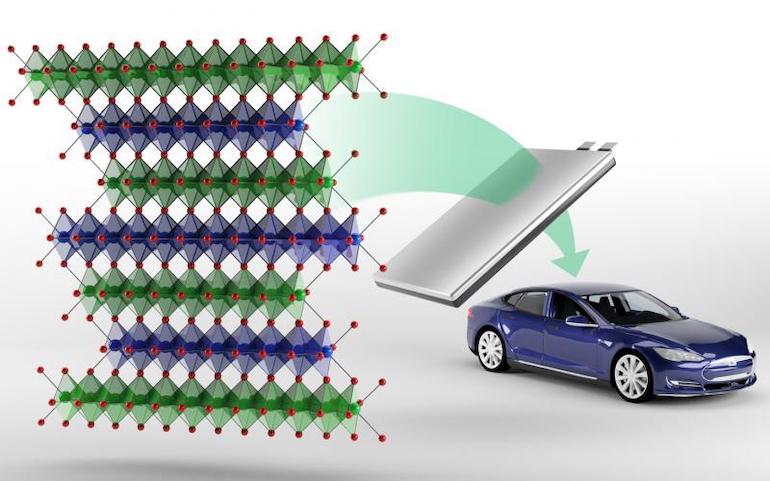

Oak Ridge National Laboratory (ORNL) researchers developed the new family of cathodes, which they said can be used in particular to develop electric vehicle (EV) batteries, as well as to power consumer electronics.

Cathodes are the positive-charged electrodes found in batteries. The new cathode class is called NFA, which stands for nickel-, iron- and aluminum-based cathode; the material itself is a derivative of lithium nickelate.

“Our investigations into the charging and discharging behavior of NFA showed that these cathodes undergo similar electrochemical reactions as cobalt-based cathodes and deliver high enough specific capacities to meet the battery energy density demands,” Ilias Belharouak, ORNL’s scientist leading the NFA research and development, said in a press statement.

Evolving Li Batteries

Researchers are eyeing new solutions for lithium-ion batteries to drive improvements required to power the next generation of portable electronics and EVs. Their investigations include the use of more eco-friendly and easily sourced materials that can drive down costs as well as provide the energy density and ability to withstand more charging cycles without degradation.

EVs have their own specific needs, keeping pace with cars that run on fossil fuels their batteries must be able to hold an ever-increasing amount of charge and energy density safely. With research predicting that more than 100 million electric vehicles will be on the road by 2030, scientists are ramping up their efforts to find new and better materials to meet their energy needs, Belharouak said.

Those materials may not include the now commonly used cobalt, a metal that comprises a significant portion of a lithium-ion battery’s cost because it is rare and largely mined overseas, making it difficult to acquire to produce the cathodes needed for high-volume battery production, he said.

That is why his team is “developing a cathode that has similar or better electrochemical characteristics than cobalt-based cathodes while utilizing lower-cost raw materials,” Belharouak said in a press statement.

‘Material of Choice’

Indeed, scientists long have known that lithium nickelate is a “material of choice” for developing cathodes, but intrinsic structural and electrochemical instabilities have limited its use, he said.

To remedy this, the team used neutron diffraction and Mossbauer spectroscopy, among other techniques, in their examination of NFA’s atomic- and micro-structures and electrochemical properties to optimize the cathodes they developed. Their work gave them insight on how to make the material better-suited to this use, Belharouak said.

“In our research, we replaced some of the nickel with iron and aluminum to enhance the cathode’s stability,” he said in a press statement. “Iron and aluminum are cost-effective, sustainable, and environmentally friendly materials.”

ORNL scientists are in the early stages of testing on their NFA cathodes, but what they have found so far is promising, Belharouak said. Because they have demonstrated that these cathodes perform on par with cobalt, it may be possible to avoid using the rare metal altogether in the future for lithium-ion batteries.

Moreover, the process to manufacture the NFA cathodes can be integrated into existing global cathode manufacturing processes, and they anticipate performance improvements as they continue their investigations, researchers said.

The team published papers on their work in the journals Advanced Materials and the Journal of Power Sources.

Researchers plan to continue to work with the NFA class of cathodes, they said. The next step will be to test the materials in large-format cells to validate the results that they achieved in the lab and further explore the suitability of these cathodes for use in EVs, they said.

Elizabeth Montalbano is a freelance writer who has written about technology and culture for more than 20 years. She has lived and worked as a professional journalist in Phoenix, San Francisco, and New York City. In her free time, she enjoys surfing, traveling, music, yoga, and cooking. She currently resides in a village on the southwest coast of Portugal.

About the Author(s)

You May Also Like