New Solutions for Mitigating Degradation in Lithium-Ion Batteries

Chemically stabilizing a cathode and applying a graphene coating can improve lithium-ion battery longevity.

April 24, 2021

One of the key problems researchers aim to solve to make lithium-ion batteries (LIBs) more viable long-term for future applications is their relatively fast process of degradation. This not only means they currently can only sustain their power density for a short lifetime, but also that they have the potential for catching fire or even exploding when they get too hot.

A team of researchers from universities in both the United States and China have new insights into how to solve this problem by studying the root of where it occurs in batteries and finding ways to mitigate it through chemistry.

“Most of the degradation mechanisms in LIBs occur at the electrode surfaces that are in contact with the electrolyte,” said Mark Hersam, a professor of materials science and engineering at Northwestern University. “We sought to understand the chemistry at these surfaces and then develop strategies for minimizing degradation.”

Specifically, the team focused on the battery’s cathode, the negatively charged electrode in a device, developing two ways to improve its performance and long-term stability.

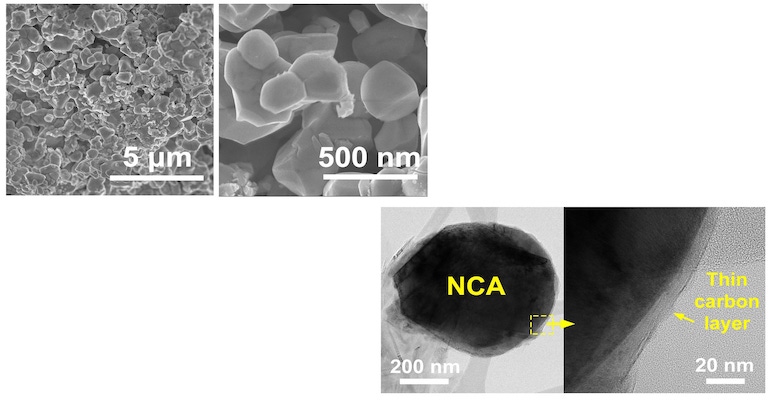

Working with nickel-rich lithium-ion battery cathodes, the team took a two-step approach to their work. First, they realized that the cathode surfaces needed to be prepared by suitable annealing, a process that heats cathode nanoparticles to remove surface impurities. It is only after this process that they then applied an atomically thin graphene coating to lock in the cathode structure, researchers said.

Building a Better Device

Researchers used graphene-coated nickel, cobalt, aluminum (NCA) nanoparticles to develop the cathodes, which they said showed superior electrochemical properties—among them, low impedance, high rate performance, high volumetric energy and power densities, and long cycling lifetimes, they said.

The graphene coating of the cathode also acted as a barrier between the electrode surface and the electrolyte, preventing premature degradation at the problematic contact point, researchers said.

While the researchers previously thought the graphene coating alone would be enough to improve performance, their results demonstrated that pre-annealing the cathode materials to optimize their surface chemistry also is a key factor in improving performance, they said.

The team published a paper on its work in the Journal of Vacuum Science and Technology A. In addition to researchers at Northwestern University, scientists from Sejong University and Clemson University also worked on the project.

Method Versatility

Though the team worked with a specific type of cathode, Hersam said the process the team used also can work with other energy storage electrodes, such as sodium-ion or magnesium-ion batteries, that incorporate nanostructured materials possessing high surface area.

“Our approach can also be applied to improve the performance of anodes in LIBs and related energy storage technologies,” he said in a press statement. “Ultimately, you need to optimize both the anode and cathode to achieve the best possible battery performance.”

Indeed, Hersam said the work can inform future research into the development of high-performance, nanoparticle-based batteries for a variety of applications that require electrodes that deliver high energy density without compromising cell lifetimes.

These include everything from EVs to consumer electronics to more large-scale, grid-level energy storage for renewable energy sources such as wind and solar, he said.

Elizabeth Montalbano is a freelance writer who has written about technology and culture for more than 20 years. She has lived and worked as a professional journalist in Phoenix, San Francisco, and New York City. In her free time, she enjoys surfing, traveling, music, yoga, and cooking. She currently resides in a village on the southwest coast of Portugal.

About the Author(s)

You May Also Like