Maximizing Battery Production: In-Line Metrology Systems for Efficiency

Discover enhanced efficiency in lithium-ion battery production through in-line control systems. Gain insights from Chuck Blanchette, Product Marketing Manager at Thermo Fisher Scientific.

The demand for lithium-ion batteries (LIBs) has risen drastically in recent years due to the ever-increasing adoption of power technologies in line with clean energy initiatives. LIBs have become a primary energy storage solution in modern society since their initial commercialization in 1991. Their rechargeable nature—due to the reversible movement of highly reactive lithium ions from the anode to cathode during charging and discharging—as well as their high energy, power densities, and long life cycle make LIBs ideal for use in portable electronic devices, electric and hybrid electric vehicles, and grid storage.

For manufacturers, the safety, longevity, and cost-effectiveness of LIBs depend on achieving an optimal thickness and coating uniformity of the cathode, anode, and separator film during production. In battery electrode manufacturing, excessive profile variation throughout the electrode coating process can not only be detrimental to performance but can also reduce product yield, making it essential to employ in-line metrology systems throughout. Chuck Blanchette, product marketing manager at Thermo Fisher Scientific, discusses in-line metrology and control systems to maximize electrode production yield and process efficiency.

The importance of electrode coating thickness

The technology inside every LIB consists of two current collectors, an aluminum cathode and a copper anode, coated on both sides with a thin film of a slurry mixture consisting of carbon, graphite, and binder, or the lithium active material. Electrode coating is a multi-step process: firstly, materials are mixed into a solvent to create a slurry; then, the metal substrate is coated with the slurry and dried to remove excess solvent; and in the final step, coated electrodes undergo calendering, a compaction process which compresses their porous structure to optimize electrochemical performance, before they can be cut to size and assembled into a cell.

Coating techniques for battery electrodes include roll coating – in which the space between two rollers determines coating thickness – and slot die, where a specific fluid volume is dispensed onto the electrode surface. To keep up with growing demands for optimal energy storage solutions, advances in these techniques are geared towards producing thinner coatings for better uniformity, fewer defects, and less waste.

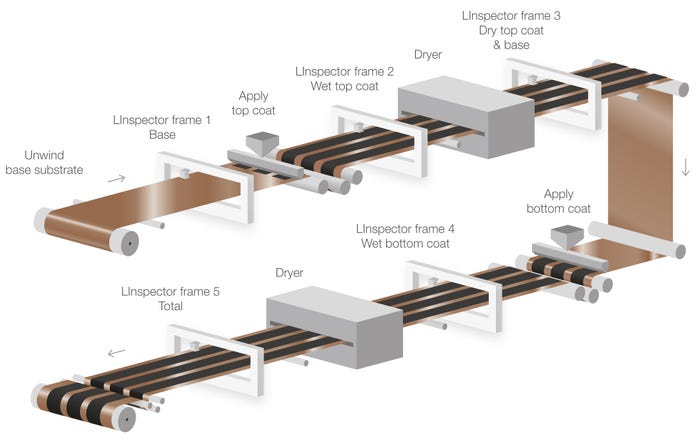

The end-to-end electrode coating process monitored and controlled at all stages. Courtesy of Thermo Fisher Scientific.

It is essential that the electrode is uniformly coated to provide comparable charge storage. This is vital for battery functionality, as an insufficient coating on the anode will not allow it to store the influx of electrons produced by the cathode during charging, leading to lithium-ion plating and possible thermal runaway. In contrast, a shortage of active cathode material can decrease the battery’s energy storage capacity. Since even minor irregularities in electrode coatings can significantly impact the production yield, geometry, and function of LIBs, implementing adequate quality assurance and in-line metrology systems during manufacturing is essential.

Taking charge of electrode coating

Previously, most processes in electrode production lines were performed manually, including machine operators' incremental adjustment of slot die openings. However, it is challenging to manually regulate electrode coating quality and identify production line defects. Developments in the LIB industry inspired scientific leaders to use their metrology knowledge and experience from other industries to advance quality control in battery production. One of these developments was the introduction of in-line thickness and coating weight gauges during electrode production. These systems scan back and forth across moving reels of electrode substrate to monitor the coating thickness in real-time and detect any defects. Three major factors to consider when implementing in-line measurement gauges in LIB manufacturing are sensor selection, scanning speed, and automated feedback loops.

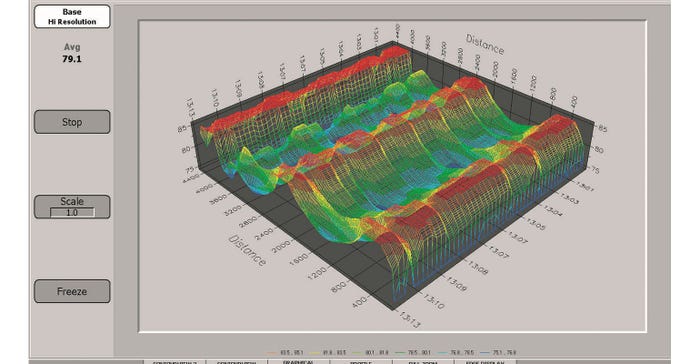

Visualization of measurement data produced by gauging systems to control the electrode coating process. Courtesy of Thermo Fisher Scientific.

Sensor selection

The ability of in-line measurement gauges to precisely detect coating variations depends on several factors, including the properties of their sensors. Various sensor technologies are available for different applications, including beta radiation absorption to control coating weight, confocal laser to measure coating thickness, and infrared emission to identify separator defects. Sensor measurement performance—which is dependent on factors such as resolution, precision, and beam size—is also essential to measure edge defects precisely and reliably during electrode production.

Scanning speed

During measurement, thickness gauges scan perpendicular to the material processing direction, tracing a zig-zag measurement path. Manufacturers need to take this into account when defining scan speed. At slower speeds, gaps in the tracing pattern could result in some defects going undetected, while sensor precision may be reduced at faster speeds. Therefore, scanning speed selection is typically a balancing act between measurement precision and the amount of material measured.

Automated controls

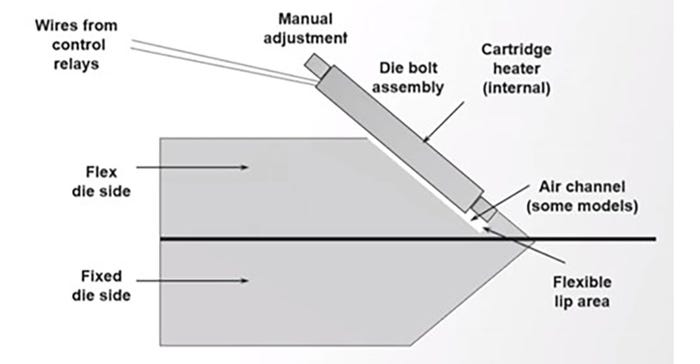

As scanning gauges measure coating thickness and uniformity, the data is fed back into the production process and can be used to optimize the electrode coating process, such as modifying production variables like slurry thickness and volume. In a simple production process, sensor-generated data is made available to machine operators, allowing them to make informed manual adjustments to the coating process. However, automated controls can be used in more advanced production lines to connect process measurement and control. For example, thermal die bolts can control automatic slot dies to increase or reduce the amount of coating dispersed to stay within the required flatness tolerance of the electrode coating. Using system-generated data to automatically adjust the thickness and uniformity of electrode coatings without interruption is known as automatic profile control (APC).

Automated slot dies containing thermal die bolts used in the downstream measurement of electrode coatings. Courtesy of Thermo Fisher Scientific .

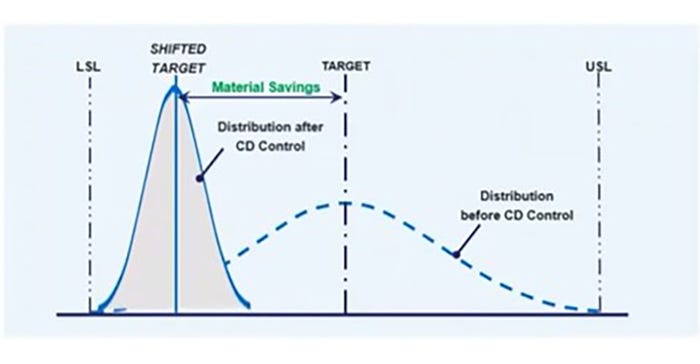

For manufacturers looking to optimize electrode production, implementing APC algorithms increases manufacturing speed and efficiency by eliminating common issues associated with more labor-intensive electrode coating processes, such as high error frequency, delays, and raw material waste. In-line metrology systems also allow for data storage, recall, and analysis so that manufacturers can resolve future issues in production lines and keep up with growing global demands.

APC showing production efficiency and raw material savings. Courtesy of Thermo Fisher Scientific.

Looking to the future

Reaching the full potential of lithium-ion chemistry is a primary focus for battery electrode manufacturers, as the annual global demand for LIBs is projected to have increased elevenfold between 2020 and the end of 2023, reaching over 2,000 GWh. This market growth will be accompanied by increasingly rigorous specifications and quality control procedures. Therefore, in-line metrology systems on electrode production lines will be necessary to ensure the production of high-quality LIBs that can power the way to a sustainable and fossil fuel-free society.

About the Author(s)

You May Also Like