The Competitive Advantage of the Connected Battery Factory

Let’s look at Honeywell’s Battery MXP manufacturing execution system (MES).

November 28, 2023

As billion-dollar gigafactories continue to sprout and grow around the world, the process of building batteries and packs at industrial scale grows ever more dynamic. Robots and other process automation applications are appearing more frequently, yet many discrete-based manual operations remain that affect production efficiency.

Late last year, industrial giant Honeywell announced its Manufacturing Excellence Platform (MXP), an integrated Manufacturing Execution System (MES) aimed at capturing production knowledge and realizing efficiency gains for the life sciences industry. Subsequently, at The Battery Show North America this past September, Honeywell showcased its manufacturing excellence platform for battery manufacturers—Battery MXP.

Alec Falzone, who leads the lithium-ion battery effort in the Americas for Honeywell Process Solutions, described the Battery MXP as bringing together technology from across the enterprise to configure and deploy for better battery manufacturing: “Our perspective at Honeywell when it comes to battery manufacturing is to deliver an end-to-end integrated solution—how do I see everything, consolidate everything, and control everything in a single platform.”

“Everything we do boils down to three pillars: safety, quality, and traceability,” he continued: Safety applies both to the battery being produced and the manufacturing environment producing it; quality impacts equally for battery materials, the battery product, and the end-user device; and traceability applies overall. “It all originates in the manufacturing environment,” he said.

Real-time cost-based feedback

In a white paper titled The Connected Future of High-Volume Battery Production, lead author Srirama Hariharan, technical solutions consultant–gigafactories for Honeywell Process Solutions, stated that in a conventional gigafactory, automation levels are low in general compared to more mature industries. As a result, thousands of manual operations are required to produce hundreds of thousands of cells daily under quality-control procedures primarily consisting of after-the-fact tests done offline in a quality laboratory. “Reducing high scrap rates and mitigating the risk of product recalls requires a paradigm shift in how gigafactories manage quality,” he stated.

With a production environment as complex as battery manufacturing, it is essential to view data capture, data management, and analysis from a holistic point of view. Imagine a scenario in a gigafactory coating line, for example, where the operator notices that electrode thickness values are lower than specified. The operator corrects that discrepancy by entering a new setpoint for the relevant parameter. A single process parameter change at a single station—mixing, coating, drying, calendaring, etc.—may constitute a correction, but lacks a view of the bigger picture and can affect both upstream and downstream operations.

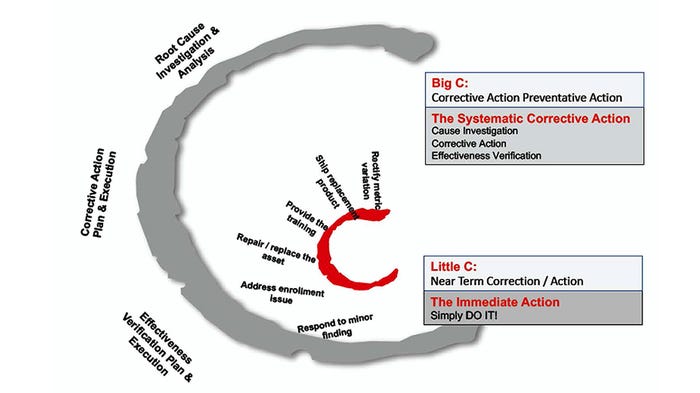

Near-term corrections (little C) drive systemic corrections (big C). Image courtesy Honeywell

“Such near-term corrective actions at a single process station can be thought of as a ‘little C,’ Hariharan noted. “On the other hand, the ‘big C’ represents systematic actions that are corrective and preventive (CAPA) when viewed from the perspective of all processing stations and processes—or perhaps all the similar events that have occurred in the past six months.”

Honeywell’s Manufacturing Excellence Platform with a connected Quality Management System (QMS) tracks production process, identifies deviations and anomalies, and provides real-time “cost-based” feedback, Hariharan concluded. “This helps to reduce quality deviations and the risk of production errors. Manufacturers can improve the efficiency, quality, and safety of their production processes, ultimately leading to increased productivity and profitability. This integrated approach of operational and quality management along with financial cost effectiveness is a key differentiator for gigafactories seeking to be successful in this rapidly expanding global industry.”

KORE control

Falzone pointed to Coeur d’Alene-based KORE Power, a lithium-ion battery developer for e-mobility and energy storage sectors, as an example. Earlier this year, KORE announced it was deploying the Honeywell Battery MXP at its KOREPlex gigafactory in Buckeye, Ariz. The KOREPlex is expected to be operational in early 2025 and will be among the first U.S. gigafactories built independently of an automotive OEM, enabling the facility to supply cells to a wide range of customers, from innovative e-mobility start-ups to utility customers seeking to improve reliability with energy storage projects. The KOREPlex is expected to have an annual production capacity of 12 GWh of high-density lithium-ion cells, with lines committed to both NMC and LFP chemistries.

With continuous closed-loop control, Honeywell’s Battery MXP will enable KORE Power to visualize and control their entire lithium-ion battery (LIB) production process in real-time, from mixing, coating, and assembly to formation and finishing. This centralized approach will allow KORE to reach target capacity faster while improving production yields, safety, and overall traceability.

KORE Power’s KOREPlex in Buckeye, AZ. Image courtesy KORE Power.

The digital Honeywell battery MXP platform lets users scale up their enterprise and achieve steady-state operations with superior yields starting from the first day of operations, the company says. Coupled with production optimization and improved efficiencies, Honeywell’s solution helps reduce consumption, enabling companies to cut their carbon footprint. Additionally, the platform provides online quality management with complete production traceability/genealogy of the cells produced.

“KOREPlex will be one of the first gigafactories utilizing increased automation to integrate end-to-end production verification and quality management for battery cell and module production, helping us increase our capacity through environmentally sustainable production practices,” stated KORE Power CEO Lindsay Gorrill in a press release.

“The future is accelerating,” Falzone added. “Battery MXP offers a way to keep up.”

To learn more about Honeywell lithium-ion battery manufacturing solutions, visit https://process.honeywell.com/us/en/industries/sheet-manufacturing/lithium-ion-batteries.

About the Author(s)

You May Also Like