Battery Tech Blooms in Britain

UK-based developers are pushing the envelope of numerous battery and EV technologies.

October 11, 2022

The strong breeze coming in off the Atlantic carries with it unmistakable scents of global opportunity and continued progress in battery and EV technology—many of which were displayed and discussed in September at the UK pavilion of The Battery Show in Novi.

UK investment in battery and clean tech is in the billions and growing, says Julian Hetherington, director, automotive transformation, at the Advanced Propulsion Centre UK (https://www.apcuk.co.uk/) Collaborating with the UK government and business development agencies like Innovate UK, APC is building on the UK’s longstanding R&D achievement record (the lithium-ion battery originated in research developed at Oxford University) to strengthen the UK battery and clean-tech ecosystem and further support and promote UK technology providers.

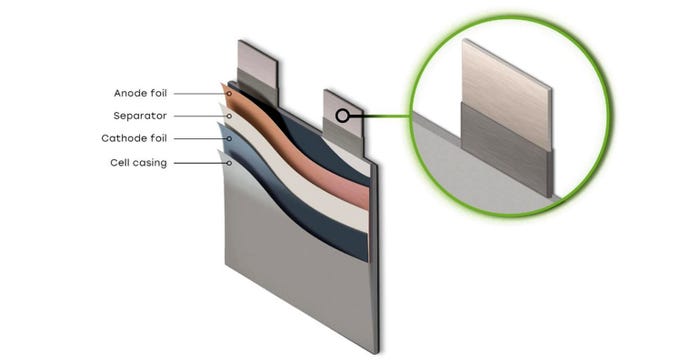

Cheshire’s ABM has a new facility for manufacturing eco-friendly cell tabs for pouch cells. The company was a grantee of Innovate UK and the Advanced Propulsion Centre.

Kieran Hall, CEO, Avocet Battery Materials (www.avocetbattery.com) says ABM, a spinoff of Avocet Precision Materials and a provider of cell tabs for pouch-cell manufacturers, was an Innovate UK grantee and part of their Global Business Innovation Programme. “We had a three-year R&D program to improve tab surface coatings,” he said. With a handful of US clients, Hall describes The Battery Show as a foot in the water for his company but found the response from attendees “amazing.”

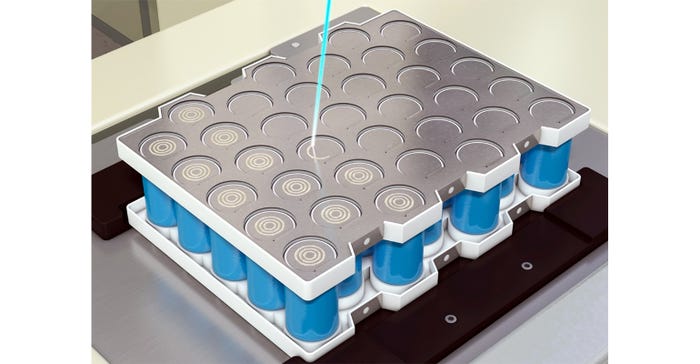

Process technology advances like electron-beam welding from Cambridge Vacuum Engineering (www.camvaceng.com) were also part of the UK pavilion. Technical Sales Manager Tony Slater has a global target for getting the word out on the benefits of EB technology over current laser-welding processes for welding batteries.

For Simon Dowson, managing director at Delta Cosworth (www.cosworth.com), it was his division’s first time at a North American show, although parent Cosworth Group has a strong U.S. engineering presence. “We are the newest addition to the Cosworth Group and are seeking new OEM and Tier One partners interested in cost-effective, high-performance advanced battery systems,” he said.

Umut Genc, CEO and co-founder of Eatron Technologies (www.eatron.com) and its AI-enabled battery management system, BMSTAR, delivers an intelligent, connected platform for OEMs and tiers. “It spans safety, quality, cybersecurity, and other compliance issues with cutting-edge BMS requirements like predictive cell diagnostics and highly accurate remaining-useful-life estimates. He found strong interest from attendees, particularly battery-pack manufacturers. “Projects are booming,” he said.

While many UK stand exhibitors wanted to meet North American potential partners and customers, Electric North East England (www.electricnortheast.co.uk) was promoting North East England’s ecosystem for interested companies. “We’re a small organization with a huge opportunity,” says Michelle Duggan, Inward Investment Manager. There is a strong automotive presence with an established Nissan plant complex, a comprehensive R&D sector, and two of the UK’s planned gigafactories under construction, Envision AESC, (up to 35GWh) and BritishVolt (30GWh).

Shyam Paw heads business development for Helix (www.ehelix.com), which designs and manufactures compact, power-dense electric powertrains for automotive, marine, defense, and commercial customers. “We had very engaging discussions at the show and had to implement a queue for those interested in our tech demonstrations,” he said. “It was very good and very busy.”

While there was a distinctly cutting-edge atmosphere permeating the UK pavilion, not all exhibitors were promoting solutions at scale. Simon Holloway, commercial director at RML Group (www.rmlgroup.com) sought low-volume customers and suppliers. The company has deep roots in motorsport and was responsible for the vehicle design and manufacture of the EV Supercar. “We supply high-performance batteries and EV engineering in low- to medium-volume applications,” he said. “We participate in The Battery Show EU and were quite impressed with the audience at The Battery Show Novi,” he added.

Transense Technologies PLC (www.transense.com) develops and licenses Surface Acoustic Wave (SAW) wireless and passive sensor systems for “really strong application potential in battery and EV systems,” says director Ryan Maughan. It delivers torque, force, temperature, and pressure measurements on rotating components without contact or wires, is insensitive to magnetic fields and has a wide temperature operating range.

Andy Bell, VP Automotive and high-value coatings for TeraView (www.teraview.com) calls his company’s measurement tech for coating density and thickness an “epiphany” for the battery and EV industry. “We can remove significant costs and optimize production with accurate measurements of both cathode & anode electrode coating thickness & density online and in real time,” he says. “North America is the #1 market and there is much more to come,” he says.

About the Author(s)

You May Also Like