Efficient Electric Vehicle Motor Made Without Rare Earth Magnets From China

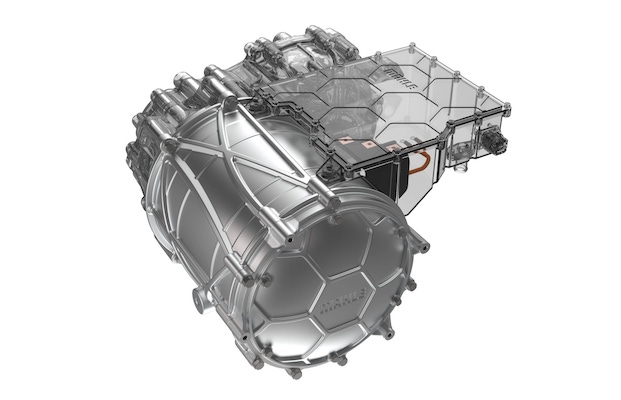

MAHLE has developed an induction EV motor that does away with expensive rare earth permanent magnets.

May 25, 2021

Sure, lithium-ion batteries get all the press when it comes to electric vehicles (EVs), but down in the trenches, doing all the real work is the electric motor. Most electric motors used in EVs use permanent magnets that are made from so-called rare-earth elements like neodymium, dysprosium, or yttrium. Despite their name, rare earth elements aren’t particularly rare, they are just difficult to extract from other minerals. However, 97% of the world’s supply comes from China, which is the only country with the ability to make the supply commercially usable.

It is possible to make electric motors without permanent magnets—BMW, Audi, and Renault for example, have models without magnets and Nikola Tesla conceived of and patented an induction motor without permanent magnets in 1883. Most magnet-free EV motors use some sort of sliding contact to provide electrical energy to the electromagnets located in the spinning rotor of the motor. These contacts can become a source of wear.

Auto supplier MAHLE is working on a slightly different magnet-free electric motor for use in EVs. Rather than permanent magnets, it uses powered electromagnetic coils in its rotor that are energized through contactless induction—there are no electrical contacts on the rotor that can wear out.

“With our new electric motor, we’re living up to our responsibility as a sustainably operating company,” says Michael Frick, Chairman of the MAHLE Management Board (ad interim) and CFO in a company news release. “Dispensing with magnets and therefore the use of rare earth elements offers great potential not only from a geopolitical perspective but also with regard to the responsible use of nature and resources.”

MAHLE claims its motor efficiency is above 95% at almost all operating speeds and torque outputs. “Our magnet-free motor can certainly be described as a breakthrough, because it provides several advantages that have not yet been combined in a product of this type,” says Dr. Martin Berger, Vice President Corporate Research and Advanced Engineering at MAHLE. “As a result, we can offer our customers a product with outstanding efficiency at a comparatively low cost.”

Breakthrough or not, the new motor design is said to be highly scalable—capable of applications as diverse as subcompact cars and giant over-the-road trucks and commercial vehicles. MAHLE has not divulged with which automakers it is working however the new motor is expected to go into production in 2023.

Kevin Clemens is a Senior Editor with Battery Technology.

About the Author(s)

You May Also Like