Marposs Unveils Measurement & Inspection Tech for Battery Makers

New battery offerings mark the company’s 60th anniversary in the US.

October 17, 2023

To measure is to know. And there are few industries where the need to know is more critical than in batteries.

In late September, global measurement and inspection technology provider Marposs Corp. welcomed customers and guests to its Auburn Hills, MI, headquarters to mark the company’s 60th anniversary in North America. Technical sessions, executive addresses, and new battery testing equipment highlighted the event.

Scott Lukomski, EV business director at Marposs, addressed the event on emerging inspection and measurement needs and applications in battery production.

There are a lot of them. In electrode manufacturing, for example, the Marposs Chromatic Confocal Sensors supply non-contact measurement for foil thickness consistency.

In coating and drying, Marposs MeSys has ultrasonic measurement for confirming density and thickness.

In calendaring, slitting, and separation, Marposs laser- and camera-based measurement equipment are used for dimensional control. Depending on production needs, technologies can be combined for overall process control efficiency, he said.

Leak testing is another area where Marposs is applying its expertise. During electrolyte filling and before sealing, some battery manufacturers also add an inert gas like helium into the cell. In this condition, a test with helium as tracer gas in a vacuum chamber can be performed to identify leaks and confirm seals.

Marposs describes its new Leak B-Tracer as an adaptable, easily retooled semi-automatic work station that can handle leak testing for cylindrical, prismatic, or pouch cells before or after formation and degassing. In addition, the Marposs PROVASET T3 or TM3 modules can be configured for pressure-decay testing completed battery modules for IP 67/68 compliance for protection against dust, liquids, and humidity.

Combined dimensional measuring and electrical testing

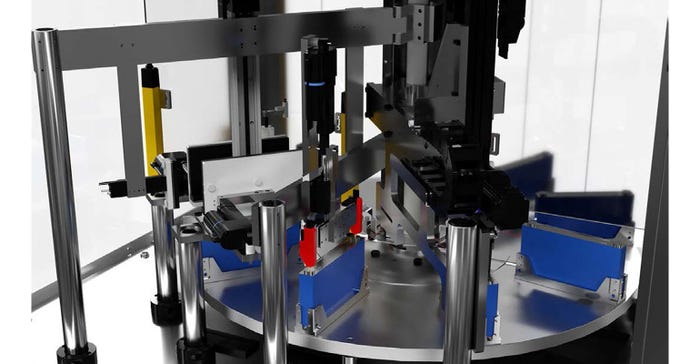

Also new on the Marposs showroom floor was the ES Elettrosystem for automated electrical testing of prismatic cells. Suitable for beginning-of-line or end-of-line testing in pilot lines, the ES can offer a multi-point contact station for measuring cell dimensions; selectable electrical tests including open-circuit voltage (OCV), alternating current internal resistance (ACIR), direct current internal resistance (DCIR), and electrochemical impedance spectroscopy (EIS); and an available station for marking or other necessary testing.

Reference nests on the ES turntable are configurable to accommodate different prismatic cell sizes and can incorporate preferred graphic codes (QR, Datamatrix, or barcode) for cell identification and test traceability. Light curtains protect the operator side and the ES can be configured for manual or automated loading scenarios. Production estimates come in at 600 to 700 cells per shift depending on cell configuration.

Go where the work Is

In 2022, Marposs, founded in Bentivoglio (Bologna), Italy, by Mario Possati in 1952, celebrated its 70th birthday in business supplying measurement and inspection technology to a wide array of manufacturing industries. As it was a first principle of Mr. Possati to put gauging and inspection on the shop floor, the idea was to "go where the work is." In 1962, the company established its first sales and service operation outside Italy in Weinstadt, Germany, near Stuttgart, and the US office in automotive-focused Michigan in 1963. The company’s scope is now truly global, operating in 25 countries with agents and distributors in a dozen more.

Acquisitions also figure in Marposs’s international growth. This year alone, the company announced it added Silicon Valley-based Solarius Development Inc., a designer and maker of precision non-contact surface inspection, visualization, measurement, and analysis equipment. In April, Marposs acquired MeSys GmbH, a German company specializing in non-contact, radiation-free measurement systems for very thin and flexible flat materials.

The company also exhibited at The Battery Show North America in September. More information on battery metrology solutions from Marposs is available at marposs.com.

About the Author(s)

You May Also Like