Europe's Battery Industry 'Caught in the Crossfire'

Squeezed by current Chinese dominance and emerging American ambitions, Europe's battery industry finds itself at a critical moment. How EU countries work together will determine its future.

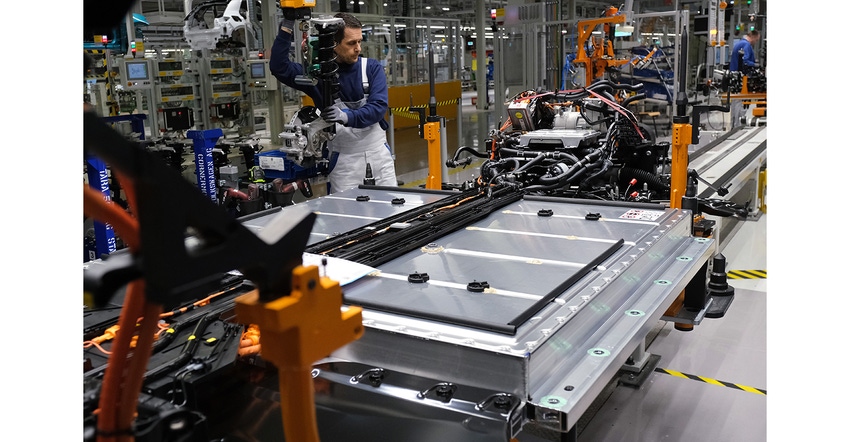

The battery industry in Europe has a lot going for it. The lithium-ion battery industry in Europe is expected to grow by more than USD 40.0 billion in 2031, according to MarketsandMarkets. The analysts cite the International Energy Agency (IEA) to note that electric vehicle sales in Europe experienced a remarkable 65% surge in 2021 compared to the previous year. The European automotive industry stands out for its streamlined production methods that prioritize efficient water and energy utilization. Additionally, the region is making notable progress in the residential sector, particularly in rural electrification projects that rely on battery energy storage systems incorporating lithium-ion batteries. Furthermore, the increasing advancements in electronic devices have fueled a greater uptake of lithium-ion batteries across Europe. Consequently, one can say that the European battery market is thriving.

But there are challenges. Like the rest of the world, the battery industry here is largely dependent on China for the acquisition and processing of required rare metals essential to battery manufacturing, and China also leads the world in battery manufacturing capacity by a wide margin.

And across the Atlantic, the United States has made an aggressive play, through its Inflation Reduction Act (IRA) and Infrastructure Act, to jumpstart its electric transformation by rewarding battery and EV manufacturing within its borders and those of its North American trading partners. Those moves have consequences for Europe: A Transport & Environment (T&E) report released in March warned that more than two-thirds (68%) of lithium-ion battery production planned for Europe has been put at risk of being delayed, scaled down, or canceled because of the US subsidies.

Julia Poliscanova, senior director for vehicles and emobility at T&E, stated at the time, “EU battery manufacturing is caught in the crossfire between America and China. Europe must act or risk losing it all. A green industrial policy focused on batteries with EU-wide support for scaling up production is urgently needed to react to US subsidies and China’s years of dominance.”

How to address these concerns was the topic of many discussions at The Battery Show Europe 2023, held in Stuttgart in late May—not least of which occurred in the opening keynote panel.

“Molecular tourism” and the need for traceability

The global battery materials supply chain is a tangled mess, with unscrupulous players using forced labor—including child labor—to gain an edge on pricing. Beyond that, it’s simply expensive and inefficient. Benedikt Sobotka, CEO of ERG and Co-Chair, Global Battery Alliance, describes the status quo this way:

“Imagine a unit of ore that’s produced in Cornwell,” he said. “It’s shipped to Dar es Salaam, where it’s then shipped to China to a refinery. From the refinery, it gets shipped to Korea��—and gets shipped back to China. Then the Chinese ship it to Japan, and Japan then ships it back to Europe. And from Europe, it ends up in a car in the United States. I call it ‘molecular tourism.’ A unit of, say, cobalt—or lithium for that matter—can travel something like 160,000 km before being put in a car.”

The challenge is, how do you make supply chains clean and transparent?

From 2024, battery makers in Europe will need to disclose the carbon footprint of their batteries and from 2027 comply with a CO2 emissions limit, regulated by the European Union with independent auditors checking compliance. But it would be beneficial for even more information than that readily available.

Global Battery Alliance, which Sobotka co-chairs, offers a solution in the form of the Battery Passport, which will become a mandatory requirement in the EU by 2026.

The Battery Passport will potentially be key to facilitating the rapid scaling of sustainable, circular, and responsible battery value chains to meet the targets of the Paris Agreement. By creating a digital twin of a physical battery, it encompasses a wide range of sustainability and lifecycle criteria. The solution introduces unprecedented levels of transparency to the worldwide battery value chain. It achieves this by gathering, exchanging, consolidating, and reporting reliable data among all stakeholders involved in the lifecycle. This includes information about the origin of materials, the chemical composition of the battery, its manufacturing history, and its overall sustainability performance.

“We put a little [QR code] marker on the back of the car. You can scan it and identify the battery, and you can tell where the materials have come from. And the carbon footprint information can be checked as well,” explained Sobotka.

Maximizing Europe’s own natural resources by simplifying the certification process

Sobotka noted that Europe contains less than 5% of the global mining industry and less than 1% of the raw materials critical to the battery industry. Nonetheless, InnoEnergy Policy Manager Ilka von Dalwigk made the case that it’s in the European battery industry’s interest to maintain and grow the resources it does have. And the way to do so is to improve the complex procedures currently in place to permit mining.

“One of the biggest bottlenecks we have is not the lack of resources but rather a lack in our current permitting processes for getting a mining project off the ground,” she said. “In terms of copper, in terms of nickel, we have resources. But when the mining industry says it’s not even looking at those deposits because the permitting process will be so cumbersome, that means there's something in the system that we need to fix.”

Responding to—and learning from—the US IRA

The impact of the IRA poses a major challenge to Europe—though it has its positive aspects as well, as some noted.

“The launch of the US Inflation Reduction Act really shook up the European ecosystem and a lot has been said--but first, I think we can congratulate the US for this massive climate effort,” von Dalwigk said. “In that respect it’s good news for everybody because it’s really pushing clean technology forward on a global scale.”

She described the IRA as having three components: customer incentives, domestic content requirements, and manufacturing incentives.

“Those latter two parts I think Europe should develop a little bit more strongly,” she said. We need to come up with a financial signal coming from Europe. More can be done to incentivize more sustainable production within Europe.”

Her organization proposes a sustainability premium or bonus for the best-in-class manufacturing projects in Europe. “It would be a kind of manufacturing incentive, and only for the best performers, to have their projects developed in Europe. It could also be coupled with IP development in Europe,” she explained. “It's still just an idea, but we are working on it. And it’s something that would set us a little bit apart and a way to match the IRA.”

Sobotka also noted the power of government money in the IRA.

“The IRA really took off when the US government poured significant subsidies behind it. And the amount of capital and then private capital that was mobilized in the process is pretty dramatic—almost unheard of,” he said. “I mean, you can probably compare it to the Second World War mobilization in the United States. I think we need to get something similar in Europe as well.

“That's one of the challenges with critical materials requirements that are coming to the EU. The announcement is nice—it reads very well, and it's quite solid. But now we actually have to put a regulatory framework in and have the ability to deploy capital to it.”

About the Author(s)

You May Also Like