GROB Systems: EV Ramp-up Goes Faster Than OEMs Had Expected

The manufacturing systems developer’s eMobility account director describes OEM and supply chain pressures and solutions.

Germany-based GROB Systems has manufacturing capabilities in the United States, Germany, Brazil, China, and Italy, with years of experience in the EV and battery fields. The company, which will be exhibiting at the EV Tech Expo in Novi, Michigan, September 13th–15th, 2022, has a unique perspective on the EV revolution and the changes it is bringing to the supply chain. Drew Steele, GROB Systems Accounts Director, e-Mobility, spoke to Battery Technology about what EV makers and their suppliers are facing.

What are the current manufacturing and production challenges facing battery and EV production?

Steele: With the rapidly emerging technologies for EV, finding qualified labor and dealing with supply chain issues have become challenges for the assembly automation industry. In addition to that, customer workforces are having to learn new, developing technologies on the fly, resulting in working with product designs that are still in flux.

How is the transition from traditional gasoline-powered automobiles to EVs affecting production and assembly from your perspective?

Steele: There is a huge demand for new capital expenditures as automotive suppliers switch from ICE [internal combustion engines] to EV, causing a monumental shift in an industry that wasn’t quite prepared for it yet.

This is in turn causing a huge demand for materials, creating supply chain issues, and driving up costs not only at the materials and component level, but also at the systems level. Current geopolitical issues that influence commodity prices such as gas and oil are influencing the migration to EV as well. The CAFE and emissions mandates and Executive Orders pushing for banning of ICE based vehicles by 2035 are forcing automotive OEMs to move faster than previously planned.

In the past, technology capabilities were the limiting factor in achieving the CAFE requirements. Now the issue is capacity and availability, not only from the raw material aspect but also the capital equipment side.

How is GROB Systems answering these challenges?

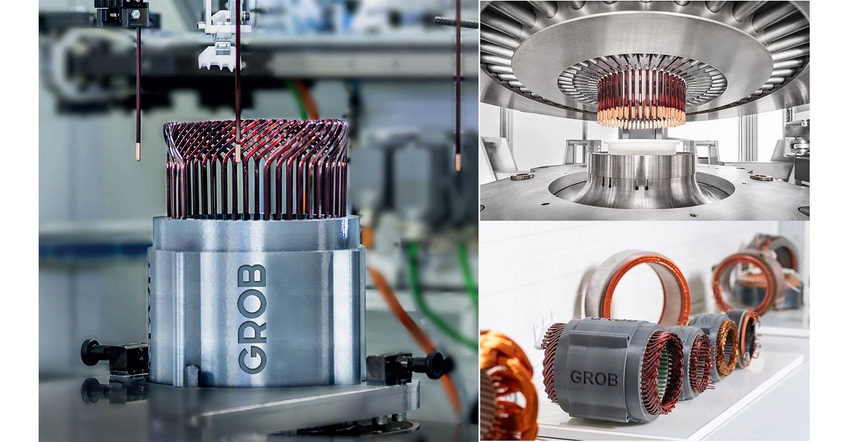

Steele: As a capital equipment supplier, GROB is doing several things to meet the industry changes and demand by increasing capacity and hiring staff in several markets, including Europe, North America, and India. GROB in Germany has developed prototyping capabilities for hairpin stators which it has replicated in China, and is currently doing the same for North America, as well as expanding technical abilities by developing battery cell manufacturing capabilities.

How is Industry 4.0 technology changing what your customers expect from you?

Steele: GROB has developed some applications for direct support of equipment for customers. With these apps, customers can remotely monitor key aspects of equipment, contact service support, order spares and much more.

Finally, what will the company be highlighting at its booth at The Battery Show and EV Tech Expo?

Steele: We will be exhibiting a wide range of solutions for electric vehicle motor components, machining and production, battery and fuel cell assembly, and more. Booth highlights will include examples of key EV parts made on GROB equipment such as stators, hairpin samples and batteries, and videos featuring GROB technology/ capabilities. For example, we’ll be featuring some battery cell assembly technology with a focus on key areas such as Z-fold and lamination stacking. In addition, experts will be on hand to discuss attendee manufacturing needs and applications.

About the Author(s)

You May Also Like