Coretec’s Silicon Anode Tech Now Under Provisional Patent

Where charging capacities can be up to 10 times higher, much longer-lasting batteries are on their way to reality. The Coretec Group’s CEO and scientists explain.

July 27, 2023

The tagline for Ann Arbor, MI-based The Coretec Group is “Engineering Silicon to Improve Life.” The company’s Endurion battery program aims to develop electric vehicle (EV) batteries with faster charging and much-improved durability compared to current options. And as more players, including emerging public and "stealth mode" companies, work on advancing silicon technology for batteries and other applications, Coretec is taking steps to secure its innovations.

In May, Coretec filed a provisional patent for its proprietary artificial solid electrolyte interfaces (SEIs). These interfaces are designed to improve silicon-based anodes for lithium-ion batteries, leading to higher densities and significantly longer battery life.

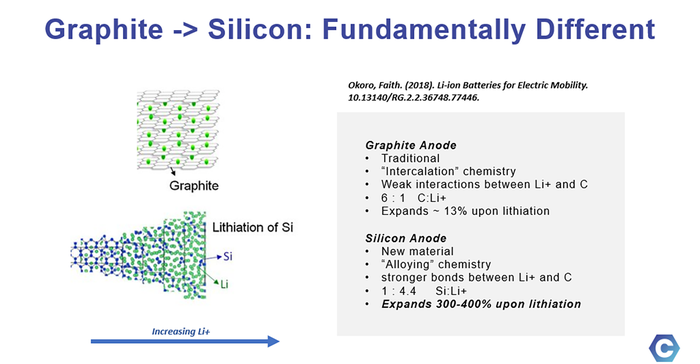

“This provisional patent is intended to protect a process that we believe is unique and possesses significant impact potential in the development of our Endurion program and battery R&D in general,” said Coretec CEO Matt Kappers. “Studies have shown that silicon anodes have the potential to increase battery charge capacity over traditional graphite anodes by as much as 10 times.”

The challenge of pulverized silicon particles

The challenge, Kappers explained at the company’s Ann Arbor headquarters, centers around silicon particles tending to pulverize during charge-and-discharge cycles, decreasing performance.

Coretec Vice President for Partnerships and Innovation Michelle Tokarz reiterated what she told Battery Technology last November: In the initial cycles of a lithium-ion battery, a solid-electrolyte interface (SEI) forms, which plays a crucial role in the battery's performance. This SEI layer acts as a passivating layer and is essential for the proper functioning of the lithium-ion battery.

![]()

“The issue comes when portions of SEI layer material break off the anode active material upon delithiation, irreversibly trapping lithium in the anode during discharge. This occurs because the SEI layer generally does not shrink with the active anode materials. In fact, it buckles and breaks. The more this happens, the more lithium is unavailable for charging/discharging.”

Such “dead lithium” is bound up in this floating SEI material and tends to cause internal resistance in the battery, resulting in poorer performance over time, Tokarz said.

‘Bottom up’ with silicon nanoparticles

At the heart of the Endurion battery program’s approach is the use of silicon nanoparticles. This forms the basis for what Coretec calls a “bottom-up” approach to better batteries.

“We can have precise control over the size, size distribution, and nature of the accompanying artificial SEI layer,” Tokarz said. Others in the industry using silicon nanoparticles largely use particles that have been created using mechanical ball-milling processes. Such methods produce order-of-magnitude larger particles, which can contribute to longer charging times and are less uniform and trickier for the kinds of surface modifications that Coretec is performing.

The Endurion program focuses on developing artificial SEI layers with tailor-made surface chemistries. These custom SEIs facilitate better pathways for lithium-ion and electronic conduction while reducing pulverization. The methods employed involve a limited number of synthetic steps, ensuring that they can be feasibly scaled up for commercial production.

‘Silicon anodes will be key’ to achieving 1000+ Wh/L batteries

Altogether, Coretec’s approach in this provisional patent could bring about battery development methods that may yield improved silicon anodes for lithium-ion and solid-state batteries.

Coretec data supports the claims outlined in the patent filing and indicate that Endurion batteries and this proprietary SEI layer can extend the life of silicon-based anodes and enable improved silicon loadings in lithium-ion batteries for more energy density.

“This patent filing is a major step forward in our Endurion battery program. Our unique approach to an artificial SEI is poised to deliver groundbreaking results, advancing silicon anode technology and making next-generation silicon-based anodes commercially viable,” said Coretec CTO Ramez Elgammal. “Silicon anodes are going to be the key to unlocking the pathway to 1000+ Wh/L batteries necessary for the demands of EVs, and our team is dedicated to further improving their capabilities, creating even more efficient, longer-lasting batteries than previously thought possible.”

About the Author(s)

You May Also Like