Are Batteries the Barrier to Better Consumer Devices?

Yes, says battery maker Enovix, but solutions are coming.

July 18, 2023

Dr. Raj Talluri, president and CEO of Fremont, CA-based battery maker Enovix, has substantial career credentials in the world of high-tech mobile devices. After receiving his Ph.D. in electrical engineering from The University of Texas at Austin in 1993, he spent 16 years in various engineering and business management divisions at Texas Instruments, nine years as a general manager and senior vice president at Qualcomm, and nearly five years as senior vice president and general manager of the mobile business unit at Micron Technology. All this before becoming being named Enovix president and CEO last December.

This hands-on participation in the continuing performance improvements in mobile devices along with the central importance of battery architecture and potential chemistry advances makes for an exciting and robust business scenario. “We believe our battery architecture or “mechanical design” enables multiple advantages over current designs including the ability to enable a 100% active silicon anode, significant safety advantages with our BrakeFlow safety system, and exceptional thermal performance enabling fast charge and reduced thermal gradients,” Talluri told this reporter. “We believe this gives us a significant advantage and our batteries are up to double the energy density compared to those on the market today.”

Lithium-ion density improvements have been meager

Are consumer electronics companies demanding more from their battery suppliers? “I’ve written about this topic a lot,” Talluri replied. Li-ion batteries power nearly all mobile devices today, but increases in Li-ion battery energy density have been meager year over year — about 4% annually from 1991 to 2022. “Our technology-related experiences are being held back due to a lack of advancements in Li-ion batteries,” particularly as device processing power, memory capacity, and mobile phone camera resolution continue advancing, he said.

Talluri cites Qualcomm’s early (circa 2012) Snapdragon chipsets having a 1GHz clock speed with a single-core CPU design. Today, it’s been published that the multi-core Snapdragon 8 Gen 2 has gone from 1GHz to 3.19GHz over 11 years, an 11% average annual increase.

Apple released its 8GB iPhone version in 2007, he continues. In 2021, Apple announced its iPhone 13 Pro had an option of 1TB of storage. “Over 14 years, that’s about a 41% average annual increase,” he said.

The camera sensors in mobile phones have improved substantially over the last 20+ years. “In 2000, we saw one of the first 0.3-megapixel cameras in a phone. By comparison, today you can purchase a smartphone with stated resolutions of up to 200-megapixels—a 33% average annual increase,” he reports.

Cellular networks advance

Finally, Talluri suggests looking at cellular network advancements. A 2G network, launched in 1991, gave us basic smartphone capability (averaging about 0.2 Mbps) and introduced phones like the Nokia 3210 “candy bar phone.” In 2019, 5G was launched in South Korea—with an average download speed of about 169.46 Mbps. That’s an average annual increase of 27%,” he noted.

“The battery has clearly held back our mobile experiences—and it’s a problem I’m excited to help solve,” Talluri said. “Enovix has developed a next-generation battery that is designed to power the mobile technologies of the future. Imagine being able to use your smartphone to its full potential. Our batteries have an increased capacity of up to double compared to many batteries in leading commercial consumer devices in the market today. And we’re just getting started.”

Differentiated technology and customer momentum

In an April 2023 presentation to investors, Enovix outlined what it calls the company’s differentiated battery technology:

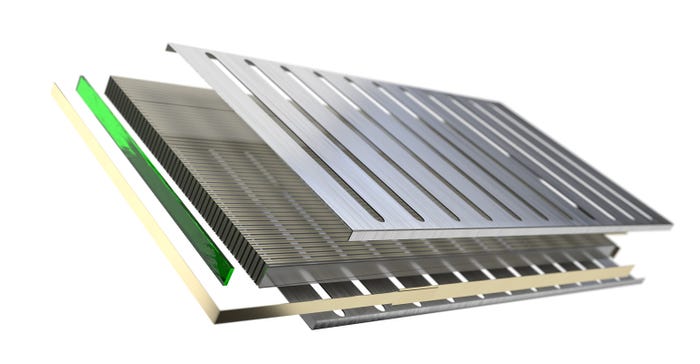

A patented battery architecture featuring a 100% active silicon anode that can store more than twice the lithium in the anode compared to graphite.

A “completely reimagined” battery architecture—throwing out the more than 100-year-old “jelly roll,” where long strips of anode, separator, and cathode are wound together in jelly-roll form, and replacing it with a precise, laser-patterned design where strips of anodes, separators, and cathodes are stacked. The results are improved packing efficiency of the active material inside the battery, enabling exceptional thermal performance and abuse tolerance, as well as accommodating the 100% active silicon anode.

Capacity retention of approximately 88% over 1500 cycles and projected 10-year calendar life based on high-temperature testing performance for its electric vehicle test cells using NMC cathodes coupled with the company’s 100% active silicon nodes.

An additional layer of safety inside the cell with the company’s patented BrakeFlow system. If an internal short does occur, with BrakeFlow incorporated, instead of a sudden catastrophic release of energy the battery is designed to discharge slowly and safely.

Substantial growth in active design wins of $718M reported in the first quarter of 2023.

“We announced our next node, EX1.5, in January,” Talluri said. “Our work on EX1.5 has included demonstrating energy density of more than 1,000 Wh/l (when adjusted to a cell-phone-size cell). We also continue to work on enhanced cycle life, a key requirement for smartphones and laptops.”

Enovix enlists

Progress continues for Enovix batteries not only in design but in scaling up manufacturing for a massive consumer electronics marketplace. In June, the company announced it has already achieved its second-quarter forecast of 18,000 units manufactured out of its Fab1 location in Fremont, and expects to exceed its quarterly guidance for the number of units produced. For the full-year 2023, the company continues to expect to produce 180,000 cells for customers from Fab1 to support broad qualification activities and customer products. Enovix previously announced it will begin high-volume manufacturing at its Fab2 location in Penang, Malaysia, next year. When fully ramped, the Gen2 Autoline 1 in Fab2 will have the capacity to produce more than nine million batteries annually.

Also announced in June was the progression of Enovix’s US Army program, with a commitment to producing commercial cells for use within U.S. Army soldier’s central power source, called the Conformal Wearable Battery (CWB). This agreement progresses this program to the next critical step towards full volume production. Created by Inventus Power, the CWB powers vital communications equipment and other devices. The Enovix cell has the potential to nearly double the energy density of the current CWB cells, which could result in substantial operational advantages including longer-lasting and lighter battery packs.

Seems as if the battery barrier may be breaking down.

About the Author(s)

You May Also Like