Why is Tesla Using Dry Battery Electrode Technology?

Dry battery electrode technology is becoming a trending topic in the EV industry. Let’s delve into the benefits this technology can offer, especially for EV batteries.

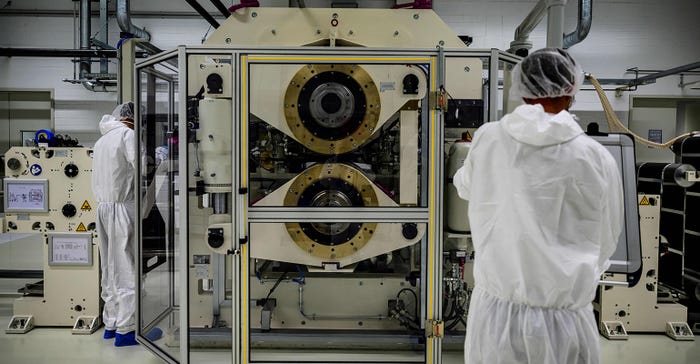

The manufacturing process—producing the electrodes and assembling the different components—makes up approximately 24% of the total cost of a battery cell. For the last three decades, batteries have been manufactured using the same processes and technologies. But recently, cell manufacturers have started to research for alternative cell manufacturing processes—such as dry battery electrode technology—that could optimize the process even more due to high demand for batteries.

But what is dry battery electrode technology?

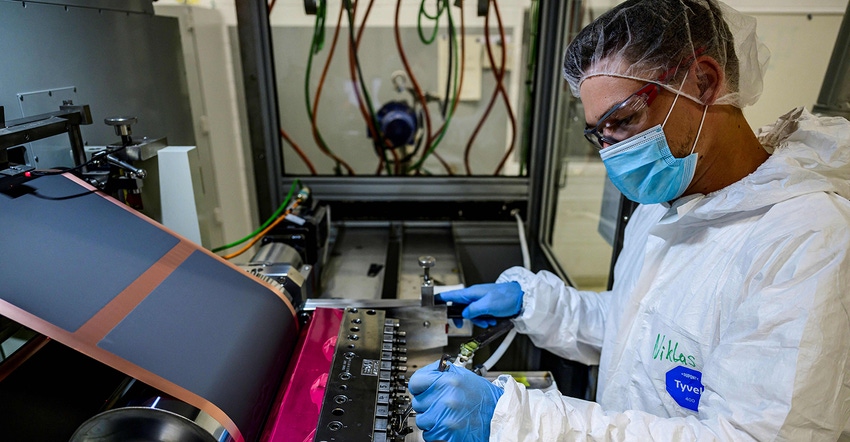

Dry battery electrode (DBE) technology is a groundbreaking and solventless method for manufacturing batteries. Unlike the traditional wet coating method, dry electrode coating process applies a dry mixture of active materials and conductive additives to the electrode substrate using a precision dispensing system.

Tesla has been actively exploring the use of dry battery electrode (DBE) technology in its battery production since acquiring Maxwell Technologies for more than $200M in 2019. According to Maxwell’s published white paper titled “Dry Electrode Coating Technology,” the technology is comprised of three steps: dry powder mixing; powder to film formation; and ) film to current collector lamination—all executed in a solventless fashion.

Tesla has been developing its own DBE technology , and the company has filed several patents related to this technology. According to the United States Patent and Trademark Office (USPTO), Tesla applied for patent related to DBE two years ago, but it was only available early this year in January. Tesla filed a patent (US 11541846 B2) tittle “Compositions and methods for dry electrode films including microparticulate non-fibrillizable binders.” The patent relates to energy storage devices, and specifically to materials and methods for dry electrode films including microparticulate non-fibrillizable binders.

Benefits of dry battery electrode technology

The adoption of this DBE technology could do more than just simplify the future of manufacturing EV batteries, due to the following advantages:

1.Environmentaly friendly: DBE eliminates the need for solvents and other chemicals used in traditional wet coating methods, which are hazardous to the environment and human health. Eliminating the slurry process (electrode materials dispersed in an organic solvent) can also reduce the energy consumption during manufacturing.

2.Improved performance: DBE can improve the performance of EV batteries by allowing more precise and uniform coating of electrodes, resulting in higher energy density, longer driving range, and faster charging times.

3.Enhanced safety: DBE improves the safety of EV batteries by reducing the risk of short circuit and other safety hazards since it is less prone to leakage or overheating.

4.Scalability: DBE is easy scalable and it hast enormous potential for large-scale EV battery production.

5.Reduced cost: DBE is more cost-effective than wet coating methods. Therefore, it can lower the cost of EV battery production and save labor time.

6.Longer lifespan: DBE can result in a longer lifespan for EV batteries, reducing the need for replacements and cost of ownership.

Based on the later advantages, dry electrode coating technology is a valuable technology for the EV industry. It is scalable and can accommodate current lithium ion battery chemistry and even have a potential use for solid-state batteries (SSB). But on the other hand, DBE is a technology in its infancy and manufacturers will likely face many challenges when they start scaling up the DBE technology.

About the Author(s)

You May Also Like