Altilium, Talga Partner for Sustainable UK EV Battery Recycling

Altilium and Talga collaborate to recycle EV batteries, ensuring sustainable anode supply in the UK.

Recycling electric vehicle (EV) batteries is crucial for sustainability, minimizing environmental impact, and conserving valuable resources. It reduces waste, lessens reliance on raw material imports, and mitigates pollution. Recycling also supports the growth of a circular economy, ensuring that materials are reused efficiently and contributing to the long-term viability of EVs and clean energy solutions.

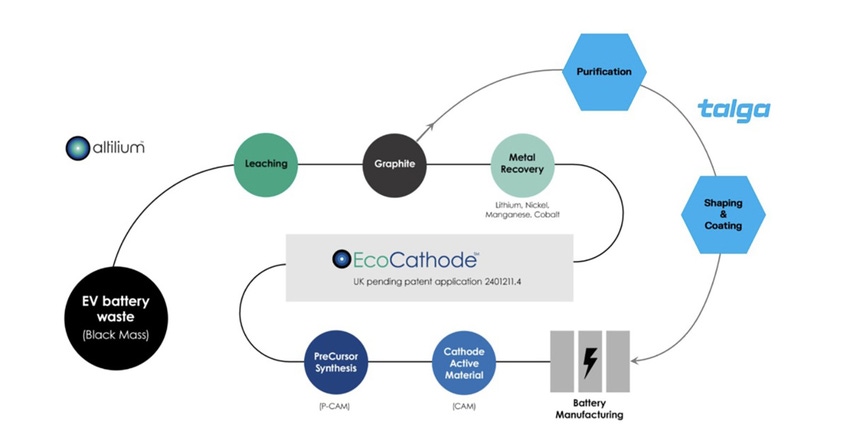

Altilium continues to forge partnerships in pursuit of a battery circular economy, this time teaming up with Talga. This partnership announcement between Altilium and Talga Group Ltd represents a significant milestone in pursuing sustainable technology and a circular economy. This collaboration is poised to address crucial challenges in the EV industry, particularly the sourcing and recycling of critical battery materials.

Graphite, a key component of lithium-ion batteries, has historically been overlooked in recycling efforts. However, innovative solutions are essential with the exponential growth of the EV market and the looming shortfall in graphite supply. By leveraging Altilium's proprietary recycling process and Talga's green anode production technology, the partnership aims to recover and reuse graphite from old EV batteries. This not only reduces waste but also lessens the UK's dependence on imported raw materials, enhancing national resilience and sustainability.

Altilium President and COO Dr Christian Marston stated, “We look forward to working with Talga to build a domestic, sustainable supply chain for low carbon graphite in the UK and leading the shift towards self-sufficiency and energy security.”

The implications of this partnership extend beyond environmental benefits. By optimizing graphite recovery and production, the collaboration contributes to developing a sustainable domestic supply chain for battery materials. This mitigates the risks associated with supply chain disruptions and strengthens the UK's position in emerging green industries.

Talga Group CEO Mr. Martin Phillips stated, “The need to secure a long-term, localized anode supply is crucial for the EV battery market. We are excited to work with Altilium in optimizing the use of recycled graphite in active anode material to enable battery makers and automotive OEMs to reduce their CO2 footprint, and to support the industry’s end-of-life battery recycling targets.”

Moreover, the announcement underscores both companies' commitment to supplying low-carbon battery materials to automotive OEMs and battery manufacturers. As the demand for EVs continues to rise globally, the significance of sustainable battery technologies cannot be overstated. By reducing CO2 emissions from the production process and enabling full battery circularity, Altilium, and Talga are driving the transition towards cleaner, more efficient transportation solutions.

The forecasted growth in UK anode demand for graphite highlights the urgency of such initiatives. With its substantial capacity, Altilium's planned Teesside recycling plant is poised to play a pivotal role in meeting a significant portion of this demand by 2030. Overall, this partnership sets a precedent for industry collaboration in advancing sustainable technology and underscores the critical role of innovation in achieving a greener future.

About the Author(s)

You May Also Like