Will Robots Show the way to Safer, Cheaper, and Faster Battery Recycling?

DOE researchers have demonstrated a safer and faster way to disassemble EV battery packs.

August 19, 2021

One of the biggest questions surrounding the adoption of electric vehicles (EVs) is the recycling of the lithium-ion batteries that power them. At present, because of the limited number of EVs on the road (in the US they make up just 2% of the market), only a small percentage of lithium-ion vehicle batteries are recycled, and the majority of the processes used to do so are not automated.

There are a number of steps involved in vehicle battery recycling—some of which can be considered dangerous. In some cases, there is a need to get through the outer housing of the pack to access battery cells and replace worn or malfunctioning components. More typically, the desire is to completely recycle battery cells within the pack for the recovery of cobalt, lithium, metal foils, and other valuable materials. In both cases, there is a need for safe and efficient handling and disassembly of the EV battery pack.

Robots

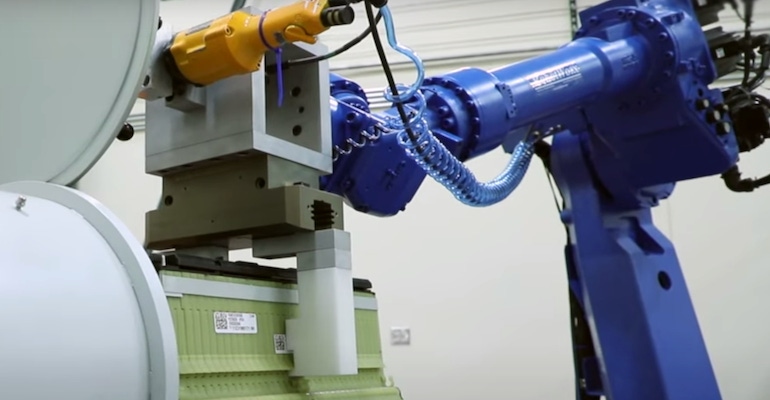

Researchers at the Department of Energy’s Oak Ridge National Laboratory (ORNL) have determined that limiting human interaction is important for both safety and efficiency and they have developed a robotic disassembly system for used EV battery packs to safely and efficiently recycle and reuse critical materials while reducing toxic waste. The robots remove bolts and disassemble the pack even if there is a remaining charge—human operators must discharge used batteries before breaking them down manually. Automated disassembly reduces human exposure to toxic chemicals found inside the batteries and high power levels that are up to the 900-volt level in some newer EVs.

“With our system, when the robot picks up the battery pack and puts it on the production line, it marks the last time a human will touch it until it’s in pieces and parts,” said Tim McIntyre, principal investigator in ORNL’s Electrification and Energy Infrastructures Division in an ORNL news release.

Faster, Safer, Cheaper

The automated system was developed as part of DOE’s Critical Materials Institute, or CMI, and can be easily configured to any type of battery pack. “Automatic disassembly of components containing critical materials not only eliminates labor-intensive manual disassembly but provides for an efficient process to separate the components into higher value streams where the critical materials are concentrated into individual feedstocks for recycle processing,” said CMI Director Tom Lograsso. “This added value is an important part of establishing an economically viable process.”

The researchers follow the same protocol each time: breaking down the used component manually and collecting data on that process to create the robotic tools and controls needed to drive an automated system, said ORNL project team member Jonathan Harter. “Industry is not limited on the amount of batteries they can take into this process. There is a significant backlog already accumulated. The limiting factor is the time it takes to perform the electrical discharge and perform disassembly manually,” Harter said. He estimated that in the time it takes in some processes to disassemble 12 battery stacks by hand, the automated system could handle 100 or more.

According to ORNL, the next step “could be building the process up to commercial scale, and McIntyre’s team also see opportunities to apply the same kind of disassembly system to electric vehicle drive trains for recovery of materials such as rare earth magnets, copper, steel and intact power electronics.” To make recycling more economically feasible, it must be done at high throughput and be flexible enough to process multiple consumer products in a single facility, according to Harter.

“If the electric vehicle market accelerates as expected in the next 10 to 20 years, we will need to address the waste stream issue and view these spent vehicles and batteries as central to the supply chain for manufacturing materials,” Harter said.

Kevin Clemens is a Senior Editor with Battery Technology.

About the Author(s)

You May Also Like