Sponsored By

Market Analysis

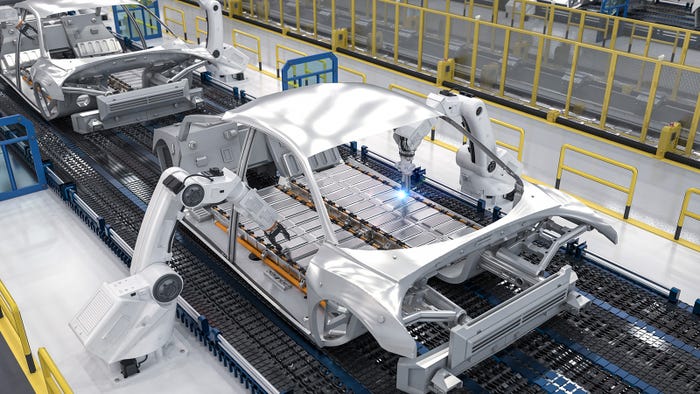

Tesla Cybertruck final assembly

Automotive & Mobility

Tesla Accelerates Plans for Entry-Level EVs, Robotaxis & IA-Powered RobotsTesla Accelerates Plans for Entry-Level EVs, Robotaxis & IA-Powered Robots

Q1 earnings call ties 4680 cell production to Cybertruck; underlines CEO Musk’s vision of Tesla as 'not a car company.'

Sign up for the Weekly Current newsletter.

.jpg?width=300&auto=webp&quality=80&disable=upscale)

.jpg?width=300&auto=webp&quality=80&disable=upscale)

.jpg?width=300&auto=webp&quality=80&disable=upscale)